boiler burner

A burner and boiler technology, which is applied to burners, combustion methods, combustion types, etc., can solve problems such as difficulty in ignition stability and burnout performance, unreasonable air distribution of burners, and low theoretical combustion maximum temperature of combustion air. To achieve excellent flame stability and burnout performance and anti-slagging performance, to ensure safe, stable and efficient operation, and the effect of a good aerodynamic field in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

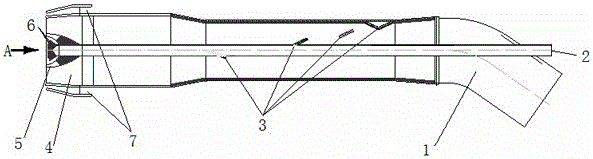

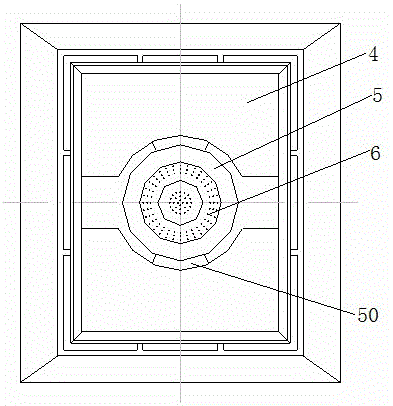

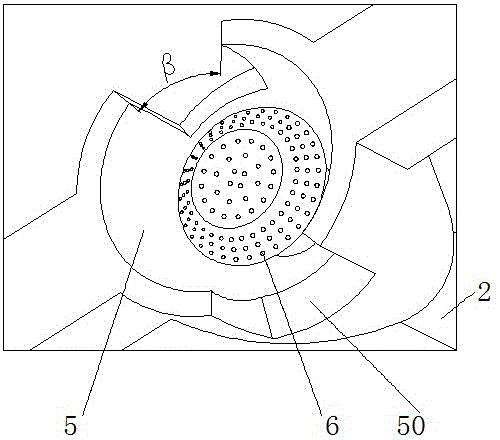

[0029] like figure 1 , figure 2 , image 3 and Figure 4As shown, the once-through burner for a boiler of the present invention includes a burner body 8, a primary air duct 1 and a pulverized coal concentrator 3 arranged in the burner body 8, and a combustion stabilizer 5 is arranged inside the burner outlet 4, and also Including an oxygen injection pipe 2 coaxial with the center line of the primary air pipe 1, the outlet of the oxygen injection pipe 2 adopts a jet hole type structure, and the oxygen injection hole 6 of the oxygen injection pipe 2 is arranged in the stable combustion body 5, and the oxygen injection The front end of the pipe 2 is connected with the combustion stabilizing body 5, and the rear end of the oxygen injection pipe 2 is connected with a translational drive mechanism, which is to adjust the oxygen injection along the direction of the centerline of the oxygen injection pipe 2 within the set adjustment stroke The position of the pipe 2 and the stabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com