Array structure fabric surface and preparing method and application thereof

An array-structured, textured technology for end-product manufacturing, chemical instruments and methods, sustainable manufacturing/processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] Preparation method of cone array textured surface

[0088] The present invention also provides a method for preparing the textured surface of the column array structure and the textured surface of the cone array structure of the present invention. Generally, a method for preparing a textured surface of a pillar array structure includes:

[0089] (a) providing a semiconductor substrate;

[0090] (b) laying a layer of polymer microsphere monolayer film on at least one main surface of the substrate, and etching the polymer microspheres in the monolayer film to form an etched The substrate of the etched polymer microsphere monolayer film;

[0091] (c) performing metal coating treatment on the substrate obtained in the previous step, thereby forming a metal thin film layer covering the upper surface of the etched polymer microspheres and covering at least part of the main surface of the substrate, so that The metal thin film layer contains a catalytic component for metal ...

Embodiment

[0118] Preparation process description

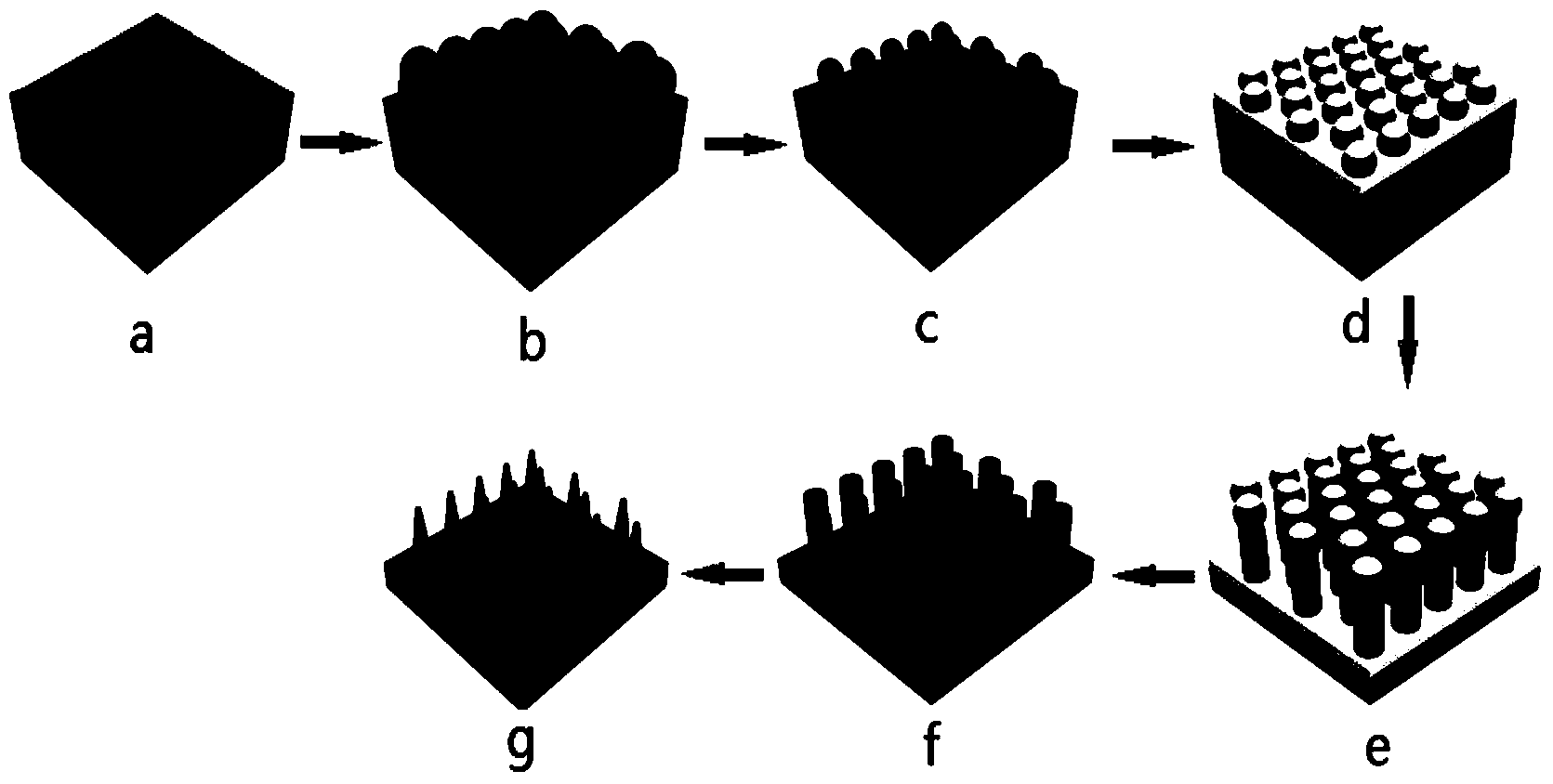

[0119] figure 1 It is the basic flow chart of the specific preparation of the pile array joint pile surface and the cone array structure pile surface in the present invention. like figure 1 As shown, the preparation process is as follows:

[0120] (1) The substrate is cleaned and ready for use, such as figure 1 a shown in .

[0121] (2) Using the drift method in the self-assembly technology to form the polymer nanosphere array, and then laying it on the substrate, the size of the polymer nanosphere can be selected from 50nm to 1000nm, such as figure 1 b shown.

[0122] (3) After the polymer nanosphere array is etched by the reactive ion etching system (RIE), the array period remains unchanged, and the diameter of the nanosphere particles in the array can be selectively regulated, such as figure 1 c shown.

[0123] (4) Using methods such as thermal evaporation, electron beam evaporation or sputtering figure 1 The surface of the s...

preparation Embodiment 1

[0128] figure 2 — Figure 4 It is a related diagram of an embodiment of the preparation method of the textured surface of the column array structure and the textured surface of the cone array structure of the present invention. This example uses a self-assembled periodic array of 300 nm diameter polystyrene spheres (PS spheres) to prepare a pillar array structured texture and a cone array structured texture.

[0129] This example uses a c-Si (single crystal silicon) sheet with a thickness of 625 μm (100) crystal plane, the resistivity is 1-10 Ωcm, and the area is 2×2 cm. Using acetone, alcohol, and deionized water, the silicon substrate was cleaned in an ultrasonic cleaning apparatus in sequence, and the time for each cleaning step was 5-10 minutes; the drift method in self-assembly was used to complete the PS ball with a diameter of 300 nm. Self-assembly on the surface of deionized water to form a layer of small spherical film arranged in an orderly period, the film shows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Vertical height | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com