Novolac resin and epoxy resin composition using the same

A novolac resin and epoxy resin technology, applied in the field of online phenolic resin, can solve the problems of heat resistance, combustion resistance, solubility, etc., and achieve the effect of improving heat resistance, combustion resistance, and excellent solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

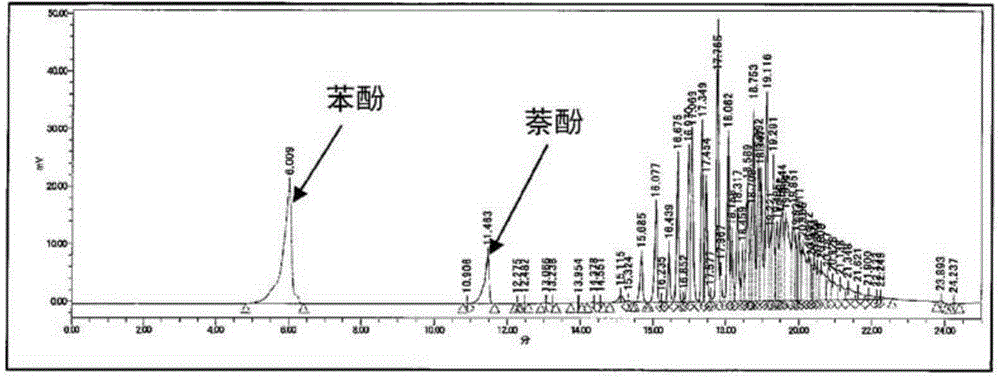

[0147] Add phenol 188.0g (2.0 mole) and α-naphthol 123.4g (0.9 mole) in the capacity of 1000mL glass flask that possesses thermometer, feeding / distillation outlet, cooler and stirrer, be heated up to inner temperature under nitrogen flow. 60°C, thereby dissolving the raw material. Add 179.3 g (0.7 mol) of 4,4'-bis(chloromethyl)biphenyl, react at an internal temperature of 60°C to 100°C for 4 hours, and then react at 165°C for 3 hours, and then pass the decompression-steam Work up to remove unreacted components of the starting material.

[0148] The softening point of the obtained novolac resin is 113 DEG C, and the hydroxyl equivalent is 263g / eq, the ratio of the unit of the general formula (2) measured by HPLC and the unit of the general formula (3) [general formula (2) Unit / unit of general formula (3)] was 30 / 70, and the ratio of the component represented by general formula (4) was 15%. The evaluation of the solubility of this novolak resin was judged to be ◯.

[0149] In...

Embodiment 2

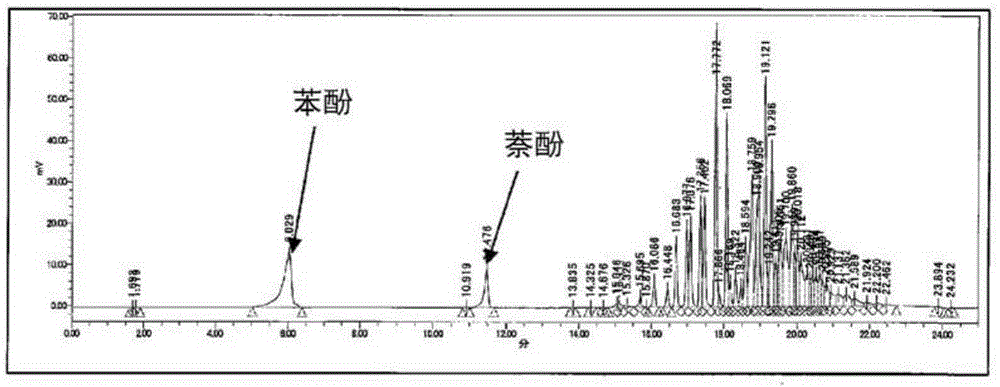

[0152] Add phenol 84.6g (0.9 mol) and α-naphthol 129.6g (0.9 mol) in the glass flask of 1000mL in the capacity that possesses thermometer, feeding / distillation outlet, cooler and stirrer, be heated up to inner temperature under nitrogen stream. 60°C, thereby dissolving the raw material. Add 180.7 g (0.7 mol) of 4,4'-bis(chloromethyl)biphenyl, react at an internal temperature of 60°C to 100°C for 4 hours, and then react at 165°C for 3 hours, and then pass the decompression-steam Work up to remove unreacted components of the starting material.

[0153] The softening point of the obtained novolac resin is 131 DEG C, and the hydroxyl equivalent is 256g / eq, and the ratio of the unit of the general formula (2) and the unit of the general formula (3) measured by HPLC [of the general formula (2) Unit / unit of general formula (3)] was 20 / 80, and the ratio of the component represented by general formula (4) was 18%. The evaluation of the solubility of this novolak resin was judged to b...

Embodiment 3

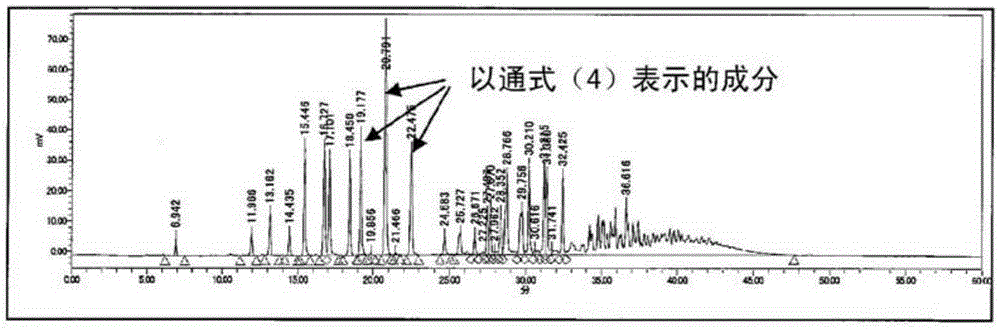

[0157] Add phenol 94.0g (1.0 mole) and α-naphthol 144.0g (1.0 mole) in the capacity of 1000mL glass flask equipped with thermometer, feeding / distillation outlet, cooler and stirrer, be heated up to internal temperature under nitrogen stream. 60°C, thereby dissolving the raw material. Add 161.9 g (0.7 mol) of 4,4'-bis(chloromethyl)biphenyl, react at an internal temperature of 60°C to 100°C for 4 hours, and then react at 165°C for 3 hours, and then pass the decompression-steam Work up to remove unreacted components of the starting material.

[0158] The obtained novolak resin had a softening point of 117° C., a hydroxyl equivalent of 247 g / eq, and a ratio of the component represented by the general formula (4) measured by HPLC was 24%. The evaluation judgment of the solubility of this novolak resin was Δ.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com