Composite soft magnetic material and production method therefor

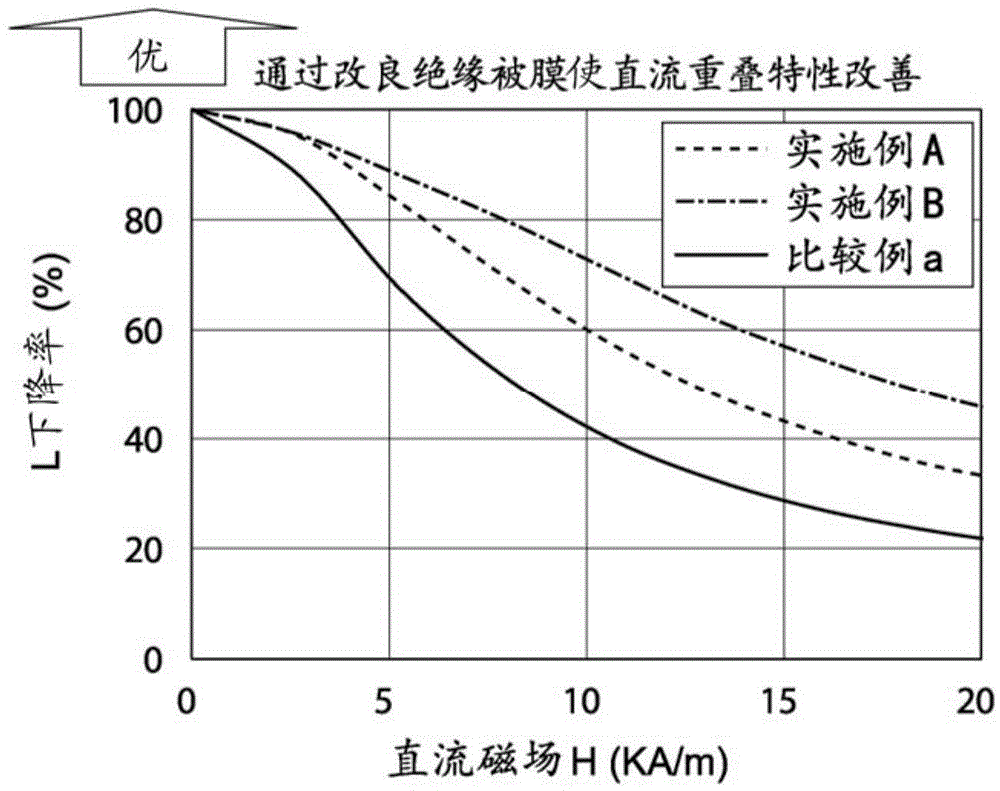

A soft magnetic composite material, soft magnetic powder technology, applied in inductor/transformer/magnet manufacturing, inorganic material magnetism, transportation and packaging, etc., can solve the problems of DC superposition characteristics deterioration, soft magnetic characteristics deterioration, silicone resin damage and other problems , to achieve good DC superposition characteristics, suppress eddy current loss, and have no thickness segregation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] As the soft magnetic powder, water-atomized pure iron powder (manufactured by Japan Hoganus Co., Ltd. S110i) with an average particle diameter of about 50 μm that has been subjected to phosphate coating treatment is used. As the silicone resin, tolyl-based (KR resin manufactured by Shin-Etsu Chemical Co., Ltd.) was used. In addition, as an inorganic insulating powder, use a specific surface area of 170 to 180m 2 / g and a hydrophobic silica powder (manufactured by Japan Aerosil Co., Ltd. R974) with an average particle diameter of about 12 nm.

[0051] First, the soft magnetic powder and the silicone resin of 0.7% by mass (the amount of the solute from which the solvent has been removed) are uniformly mixed with the soft magnetic powder, and dried at 50° C. for 5 hours while stirring, and then the used Silicone resin coated soft magnetic powder coating powder.

[0052] Next, the coating powder and 0.5% by mass of inorganic insulating powder relative to the soft magnet...

Embodiment 2

[0056] The timing of mixing inorganic insulating powder and its influence on the density, specific resistance and magnetic permeability of the sample were investigated. The same raw materials as in Example 1 were used as raw materials, and the conditions were the same as in Example 1 unless explicitly stated.

Embodiment C

[0058] First, soft magnetic powder and 0.7% by mass of silicone resin relative to the soft magnetic powder were uniformly mixed and dried while stirring to obtain a coated powder in which the soft magnetic powder was coated with the silicone resin.

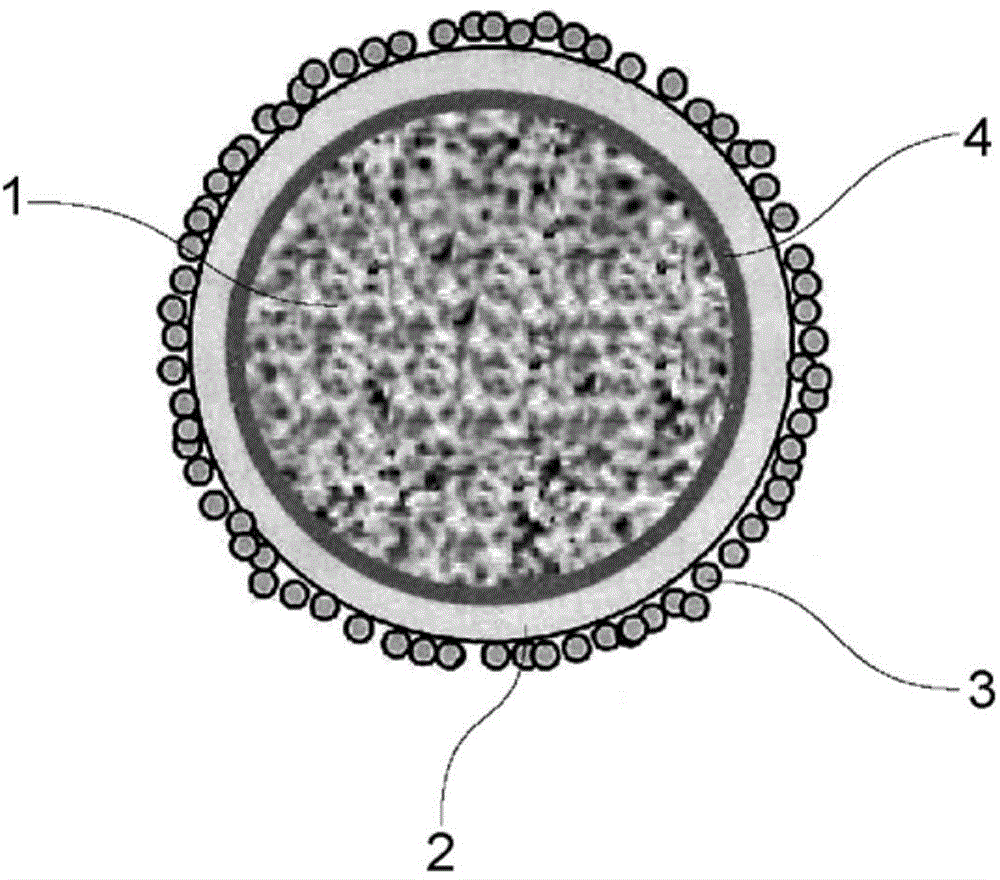

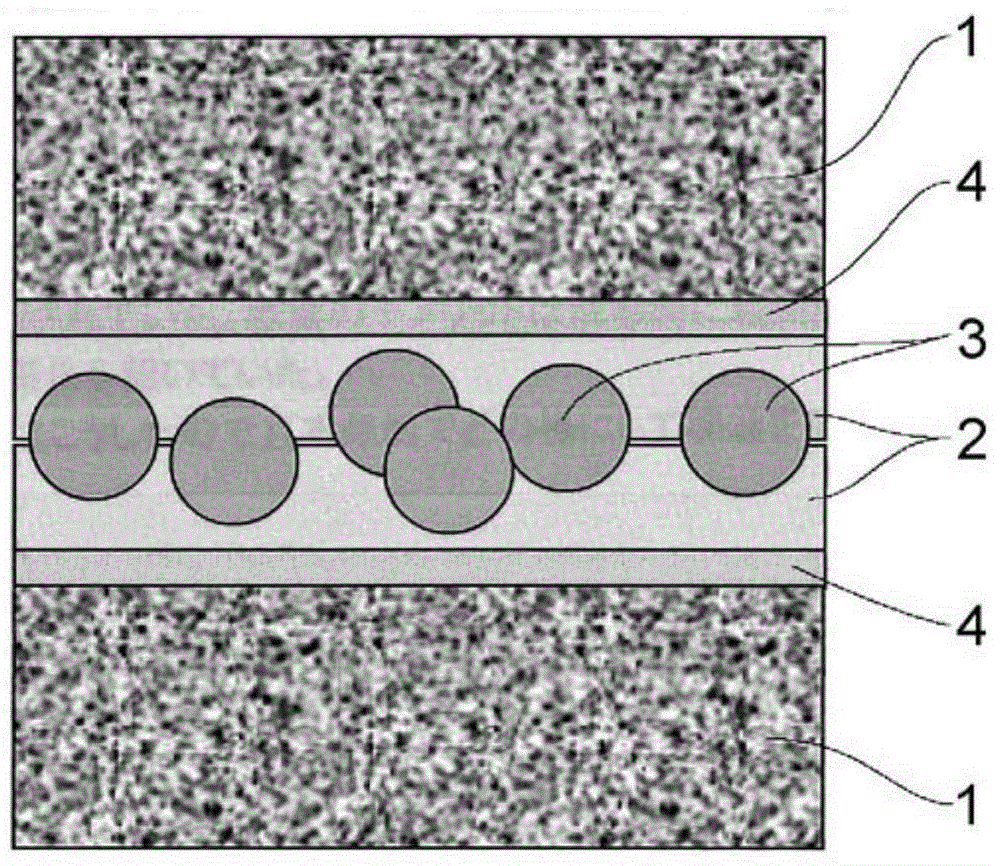

[0059] Next, the coating powder and 0.5% by mass of inorganic insulating powder relative to the soft magnetic powder were uniformly mixed. The powder at this time, such as Figure 4 As shown in (a), the inorganic insulating powder adheres to the outside of the silicone resin coated with the soft magnetic powder.

[0060] Further, add 0.8% by mass of lubricant relative to the soft magnetic powder, and the mixture is molded at a molding pressure of 8t / cm 2 or 12t / cm 2 After molding, firing was carried out for 30 minutes in a nitrogen atmosphere at 620°C.

[0061] Through the above operations, prepare respectively A ring-shaped sample was wound with a coil (the number of coils N=50 turns), and the inductance was measured by usin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com