A kind of food waste sorting and screening process

A food waste and sieving technology, applied in the direction of solid waste removal, etc., can solve the problems of food waste easy to deteriorate and smell, the distribution of food waste is scattered, and the utilization rate is less than 40%, so as to improve the utilization value and save The effect of low resource and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

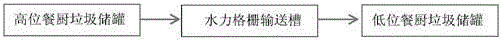

[0025] 1. One-stage sieving, the process flow is as follows: figure 1 shown.

[0026] The collected food waste is put into the high-level food waste storage tank by the bucket elevator, and discharged into the hydraulic grid conveying tank from the sewage outlet at the bottom of the storage tank. The upper end of the hydraulic grid conveying tank is a receiving hopper, and there are cleaning teeth in the receiving hopper The rake tore apart the plastic bags and food boxes wrapped in some garbage, exposing the garbage and facilitating recycling; the hydraulic grid conveying trough is inclined at 25 degrees, and the garbage moves downward with the water flow from the high-end hopper, and passes through the large, medium and small three-layer grids. Barriers, so that food packaging bags, food boxes, chopsticks, fish, meat and bones are intercepted; relatively soft materials are conveyed into the low-level kitchen waste storage tanks, and food packaging bags are manually sorted an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com