High mixing amount iron tailing sand high intensity concrete and preparation method thereof

A technology of iron tailings and concrete, which is applied to concrete, the preparation of the concrete, and the field of high-strength concrete with a large amount of iron tailings, which can solve the problems of no specific guidance plan, less utilization of iron tailings, and discharge of iron tailings and other issues, to achieve the effect of saving natural sand resources, improving cohesion, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

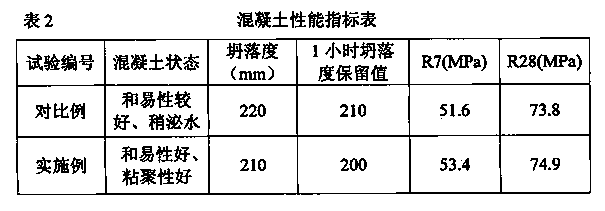

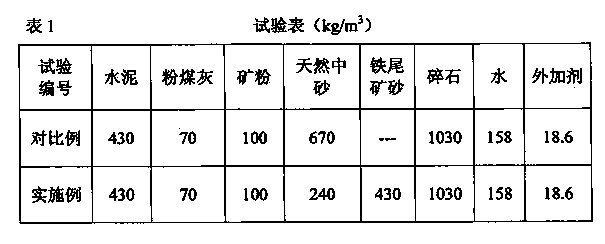

Embodiment 1

[0013]

[0014]

[0015] From the analysis of the above test results, when the proportion of iron tailings sand replacing natural medium sand is appropriate, and compound admixtures are added, the working performance of concrete can be significantly improved, mainly manifested in the better cohesion of concrete, bleeding and segregation. The phenomenon is reduced, the water retention is enhanced, and the addition of iron tailings has no effect on the strength of the concrete.

Embodiment 2

[0016] Embodiment 2: The high-strength concrete with large amount of iron tailings sand is made from the raw materials of the following components: mixed sand, cement, fly ash, mineral powder, crushed stone, water, composite admixture, each component The weight ratio is a conventional ratio, in which the mixed sand is iron tailings and natural middle sand (natural sand), and the weight percentage of iron tailings replacing natural middle sand is 60%~70% of the total weight of iron tailings in the mixed sand. % (choose 60% or 70%), the fineness modulus of the iron tailings is 1.9~2.6. The above composite admixture is made of polycarboxylic acid high-efficiency water reducer and polyether polyol in a weight ratio of 1:1. ~100,000 polyether polyol), polycarboxylate high-efficiency water reducer is a commodity sold in the market, its solid content can be 10%~15%, and the water reducing rate can be 25%~30%. The weight percentage of the composite admixture in the cementitious mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com