A kind of preparation method of attapulgite-based MQ silicone resin

A technology of organosilicon and attapulgite, which is applied in the field of preparation of attapulgite-based MQ silicone resin, to achieve the effects of strong adsorption performance, high heat resistance and large surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

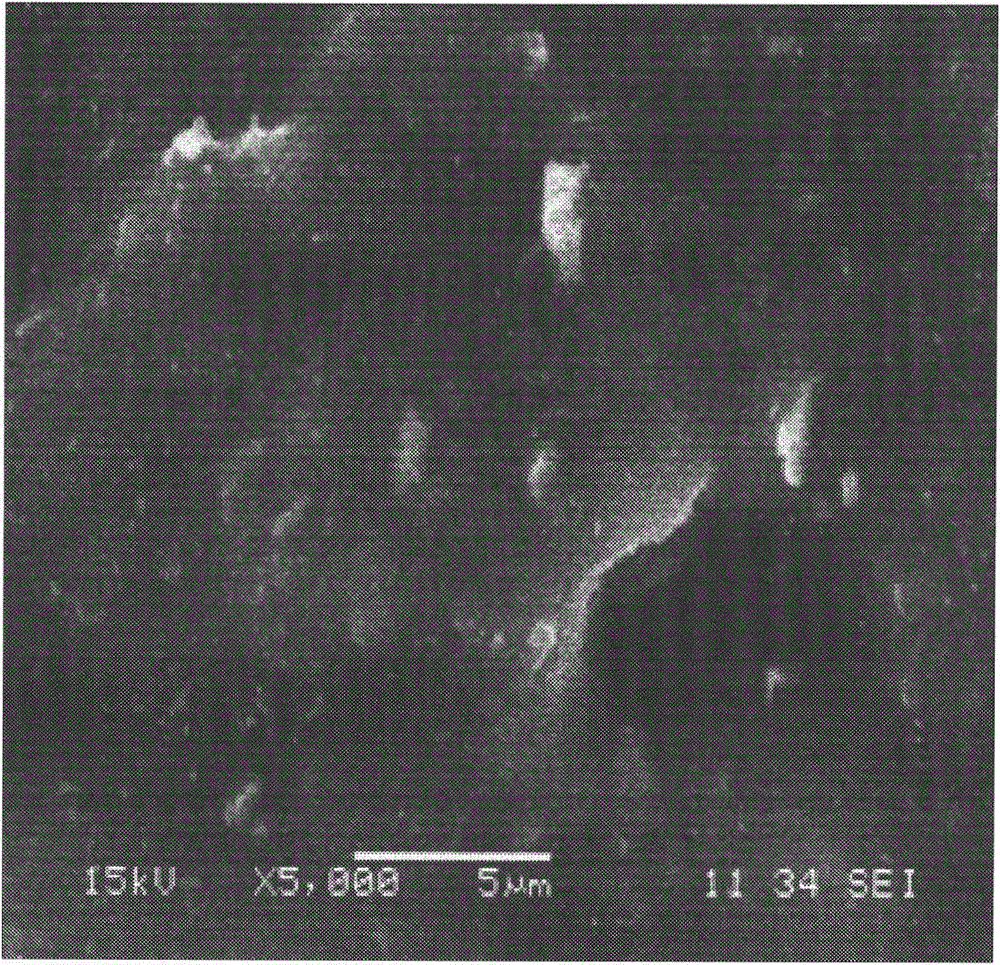

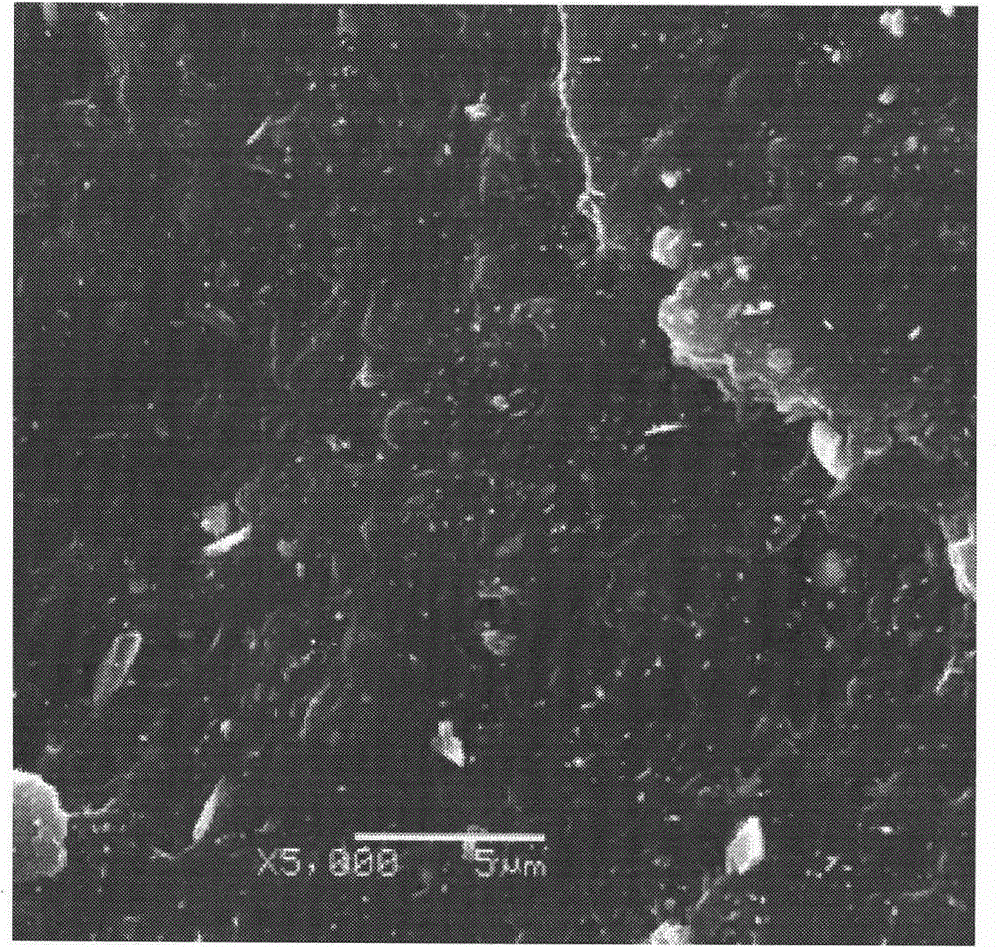

Image

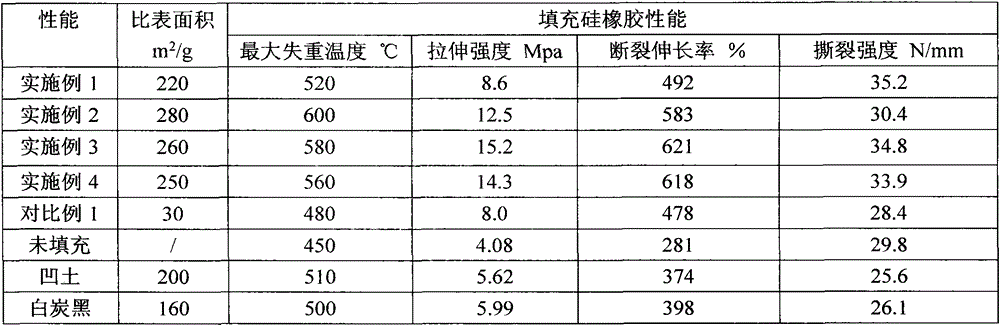

Examples

Embodiment 1

[0028] 1. Preparation of fibrous nano silica and water glass mixture: disperse attapulgite into sodium hydroxide solution, stir at 100°C for 24 hours to prepare fibrous nano silica and water glass mixture, in which sodium hydroxide The concentration of the solution is 20mol / L, and the mass ratio of attapulgite to sodium hydroxide solution is 0.05:1;

[0029] 2. Preparation of attapulgite-based MQ silicone resin dispersion: under constant stirring, add the mixture of fibrous nano-silica and water glass to concentrated hydrochloric acid, adjust the pH value to 0.5, hydrolyze for 1 min, and then add hexamethyl di Ethanol solution of siloxane, co-hydrolyzed for 120min, the mass ratio of hexamethyldisiloxane and attapulgite initially added was 1:1, and the co-hydrolysis temperature was controlled at 100°C to obtain attapulgite-based MQ silicone resin dispersion ;

[0030] 3. Post-treatment: extract with toluene, take the upper oil layer, wash until neutral and then dry at 120°C to...

Embodiment 2

[0032] 1. Preparation of the mixture of fibrous nano-silica and water glass: disperse attapulgite into potassium hydroxide solution, stir at 20°C for 0.5h to prepare a mixture of fibrous nano-silica and water glass, in which The concentration of potassium solution is 0.5mol / L, and the mass ratio of attapulgite to potassium hydroxide solution is 0.25:1;

[0033] 2. Preparation of attapulgite-based MQ silicone resin dispersion: under constant stirring, add a mixture of fibrous nano-silica and water glass to concentrated hydrochloric acid, adjust the pH value to 5, hydrolyze for 60 minutes, and then add trimethyl chloride The methanol solution of silane was co-hydrolyzed for 1 min, the mass ratio of trimethylchlorosilane to initially added attapulgite was 0.01:1, and the co-hydrolysis temperature was controlled at 20°C to obtain an attapulgite-based MQ silicone resin dispersion;

[0034] 3. Post-treatment: extract with xylene, take the upper oil layer, wash until neutral and then...

Embodiment 3

[0036] 1. Preparation of the mixture of fibrous nano-silica and water glass: disperse attapulgite into sodium hydroxide and stir at 80°C for 4 hours to prepare a mixture of fibrous nano-silica and water glass, in which the sodium hydroxide solution The concentration is 10mol / L, and the mass ratio of attapulgite to lye is 0.1:1;

[0037] 2. Preparation of attapulgite-based MQ silicone resin dispersion: under constant stirring, add the mixture of fibrous nano-silica and water glass to concentrated hydrochloric acid, adjust the pH value to 2, hydrolyze for 15 minutes, and then add γ-aminopropyl The absolute ethanol solution of γ-aminopropyltriethoxysilane was hydrolyzed for 60 minutes. The mass ratio of γ-aminopropyltriethoxysilane to the initially added attapulgite was 0.1:1, and the cohydrolysis temperature was controlled at 80°C to obtain attapulgite Earth-based MQ silicone resin dispersion;

[0038] 3. Post-processing: extract with silicone oil, take the upper oil layer, was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com