Extraction method for bioactive collagen

A technology of biological activity and extraction method, applied in the field of biological active collagen extraction, can solve problems such as insufficient hydrolysis, and achieve the effect of reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

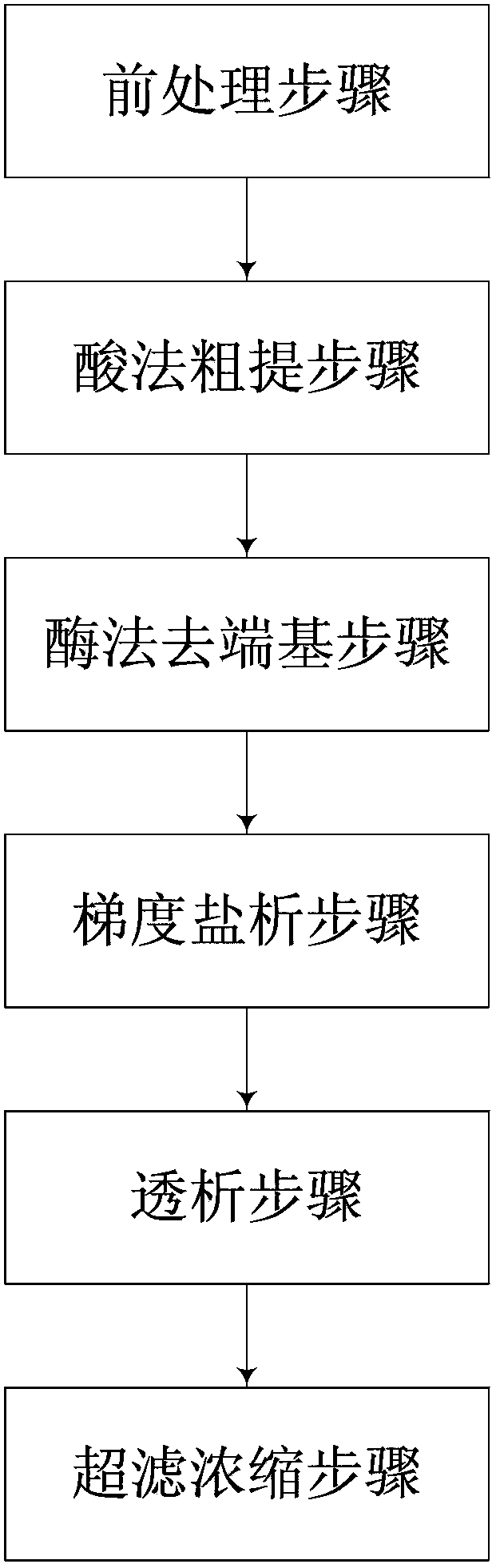

Method used

Image

Examples

Embodiment 1

[0049] (1) In the pretreatment step, the fresh beef Achilles tendon is washed with cooling pure water and cut into small pieces, and the cells in the animal tissue are removed by using the decellularization method. The specific method is to use a sodium chloride solution with a mass percentage of 10% Soak and stir for 2 hours, then use ultrasonic treatment for 0.5 hours, then soak and stir with 0.3% sodium dodecylsulfonate solution for 2 hours, then soak and stir with 5% sodium chloride solution for 2 hours, and then use ultrasonic Treat for 0.5 hours, then soak and stir for 2 hours with 0.2% sodium dodecylsulfonate solution by mass percentage, and finally wash with cooling pure water, put it into a tissue grinder and pound into tissue debris, and the tissue debris After cleaning and filtering the scraps, soak them in 1.5% sodium hydroxide solution for 2 hours, wash and filter again, and put the tissue scraps for use;

[0050] (2) Rough extraction by acid method, take 1 part b...

Embodiment 2

[0056] (1) The pretreatment step is to wash the fresh cowhide with cooling pure water and cut it into small pieces, and use the decellularization method to remove the cells in the animal tissue. The specific method is to soak and stir with 5% sodium chloride solution 2 hours, then ultrasonic treatment for 1 hour, then immerse and stir with 0.2% sodium dodecylsulfonate solution for 3 hours, then soak and stir with 1% sodium chloride solution for 2 hours, and then use ultrasonic treatment for 1 hour hours, then soak and stir with 0.05% sodium dodecylsulfonate solution by mass percentage for 2 to 3 hours, and finally wash with cooling pure water, put it into a tissue masher and mash it into tissue debris, and the tissue debris After the scraps are cleaned and filtered, they are soaked in 0.1% sodium hydroxide solution for 4 hours, washed and filtered again, and the tissue scraps are used for later use;

[0057] (2) Rough extraction by acid method, take 1 part by weight of filtere...

Embodiment 3

[0063] (1) The pretreatment step is to wash the fresh pigskin with cooling pure water and cut it into small pieces, and use the decellularization method to remove the cells in the animal tissue. The specific method is, for example, soak it in a 7% sodium chloride solution by mass Stir for 1.5 hours, then use ultrasonic treatment for 0.8 hours, then soak and stir with 0.25% sodium dodecylsulfonate solution for 2.5 hours, then soak and stir with 2.5% sodium chloride solution for 1.5 hours, and then use ultrasonic treatment 0.8 hours, then soaked and stirred for 2.5 hours with 0.1% sodium dodecylsulfonate solution by mass percentage, and finally washed with cooling pure water, put into a tissue grinder and smashed into tissue debris, the tissue debris After cleaning and filtering, soak in 0.12% sodium hydroxide solution for 3 hours, wash and filter again, and set aside tissue debris;

[0064] (2) Rough extraction by acid method, take 1 part by weight of filtered tissue debris in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com