Method for preparing wave-shaped junction surface metal laminated plate through laser cladding

A technology of laser cladding and joint surface, which is applied in the direction of metal material coating process and coating, and can solve problems such as cracks and differences in physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

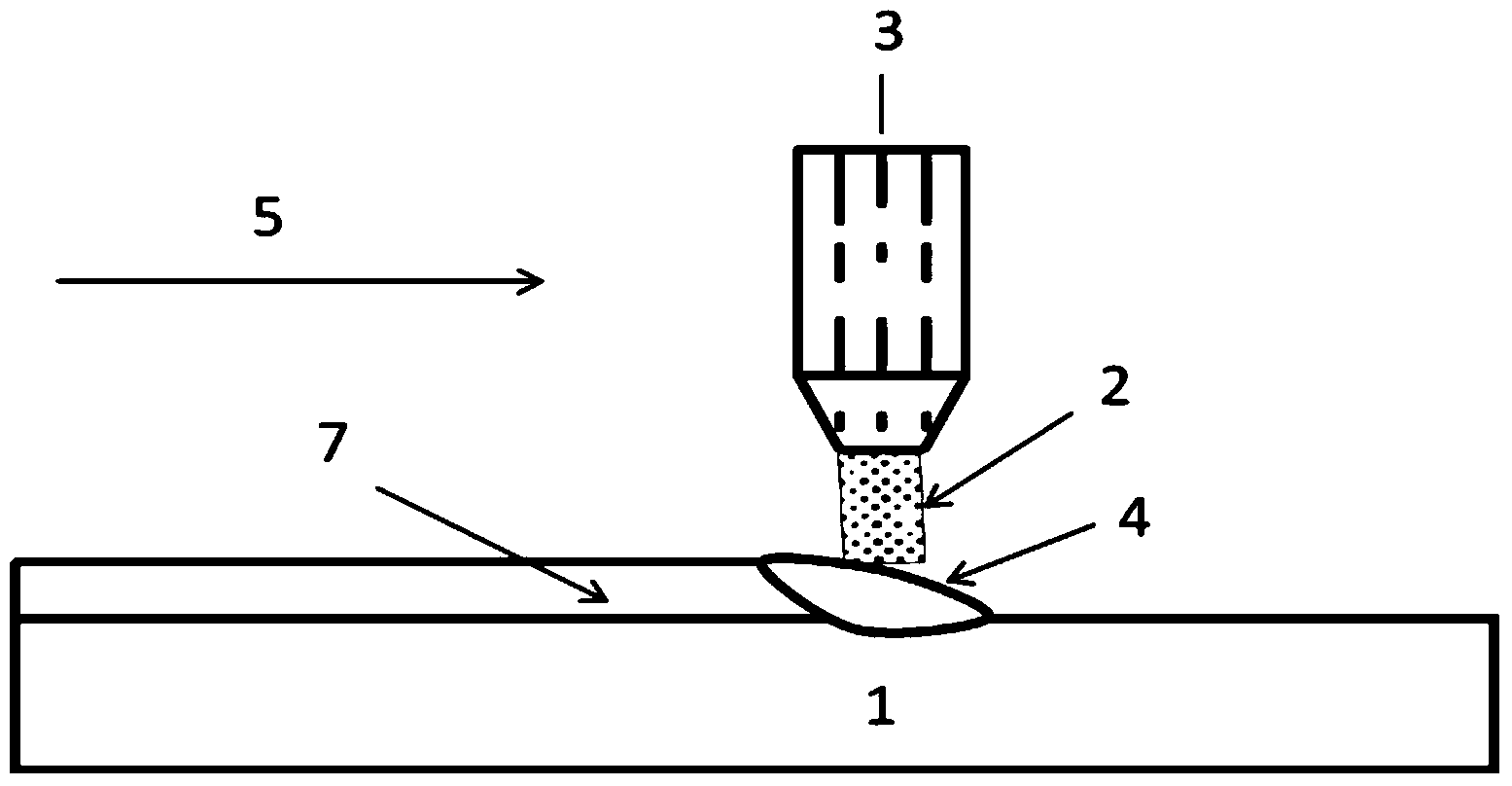

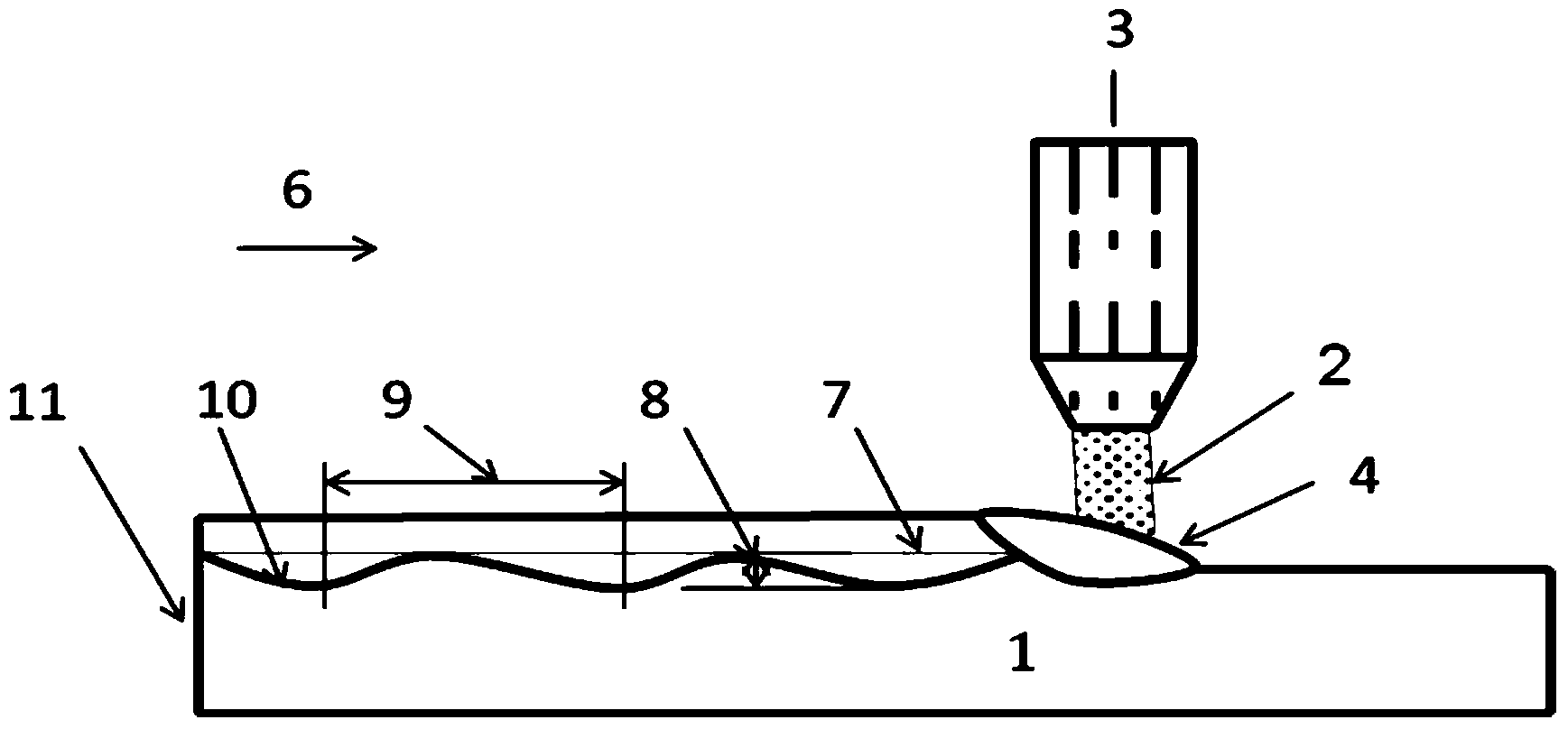

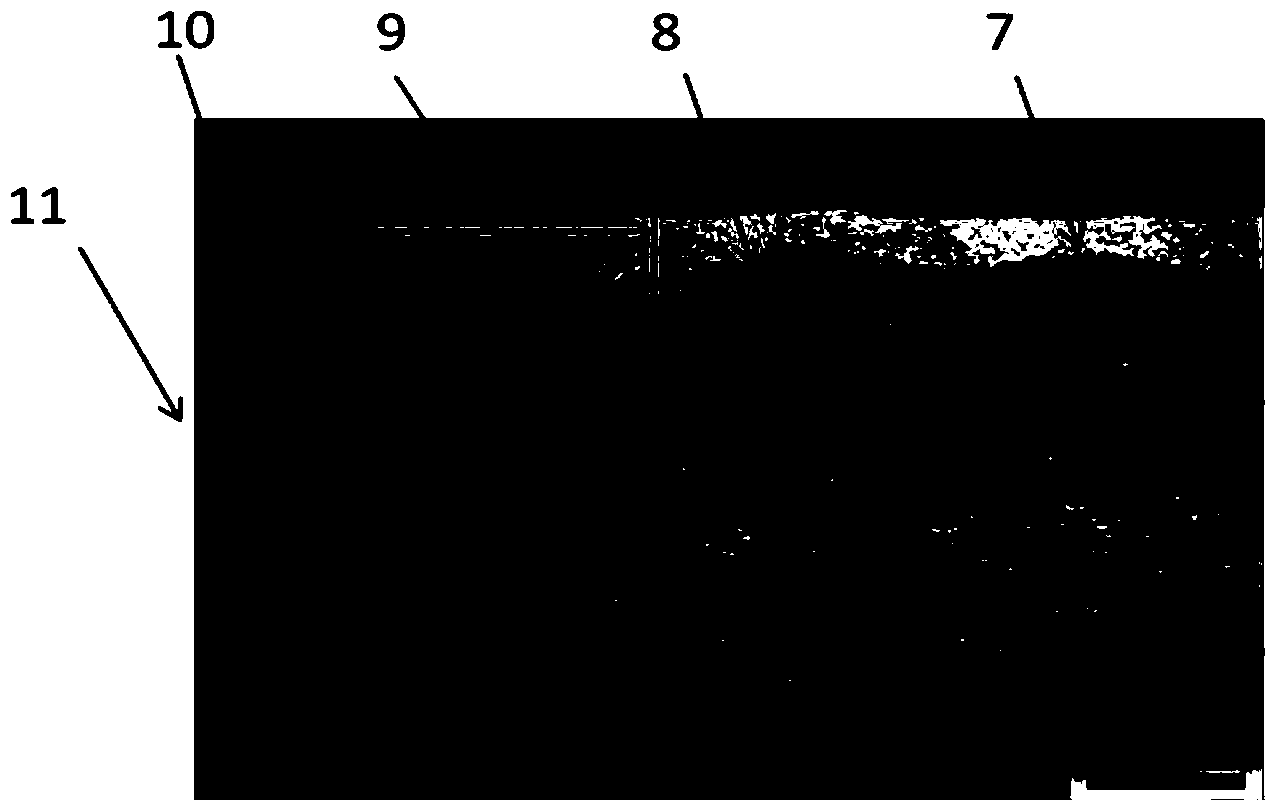

[0015] Before laser cladding, the composite surface of the carbon steel plate is ground to reveal a fresh, flat and clean processed surface, which is beneficial to the mutual diffusion between the two metal atoms during the cladding process and realizes metallurgical bonding. At the same time, the 304 stainless steel powder is dried to improve the fluidity of the powder, and argon is used as the protective gas. A continuous Nd:YAG solid-state laser is used, the power is 550-640W, the scanning speed is 300-500mm / min, the powder feeding amount is 2g / min, the overlap coefficient is 0.3, and the spot diameter is 2mm. Place the carbon steel substrate 1 on the laser processing workbench, turn on the laser beam 3 to irradiate the surface of the plate carbon steel substrate 1, and at the same time convey the coating stainless steel powder 2 coaxially and synchronously, and irradiate and heat the high energy density laser beam 3 to make the coating The surface of the layer powder 2 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com