Architectural engineering construction device based on 3D printing technology and application method

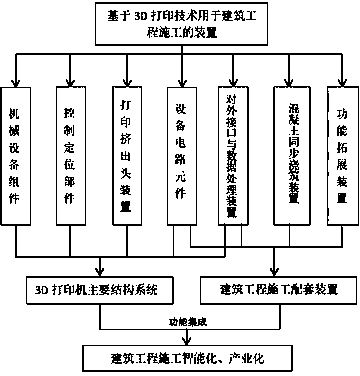

A kind of construction engineering and 3D printing technology, which is applied in the direction of construction, building structure, and building material processing, etc., can solve the problems of being greatly affected by the climate environment and the large demand for labor, so as to reduce labor input, reduce labor force, and ensure construction The effect of quality and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

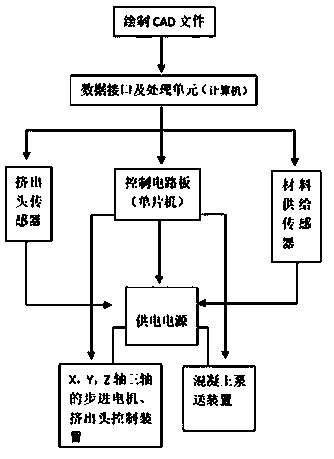

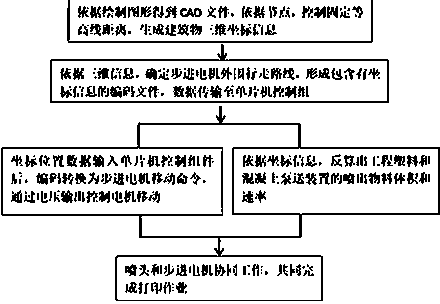

Method used

Image

Examples

Embodiment

[0037] Such as Figure 4 Shown: During the construction process of the construction project, the upper main structure (beams, slabs, columns) of the building to be "printed" is located in the middle of the two X-axis movement control axles 2 . In the process of 3D printing of templates, the printing of space objects is realized through the movement and positioning of three coordinate axes, and the movement and positioning of different axes are the result of the synergy of the corresponding guide rails, wheel shafts and motor control devices. Among them, the movement in the X-axis direction is realized by two guide rails 1 and two stepper motors 7; the movement in the Y-axis direction is realized by a guide rail 4 and a stepper motor 6; the movement in the Z-axis direction is realized by two guide rails 3 and two stepper motors 5 to achieve. Extrusion head 8 for formwork making and its control device 10, discharge port 9 for concrete discharge and pouring, concrete pump 11 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com