Tin-iron composite steel pipe

A composite steel pipe and tin-iron technology, applied in tubular components, lighting and heating equipment, heat exchange equipment, etc., can solve the problems of less than 2 years of service life, poor dew point corrosion resistance, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific implementation

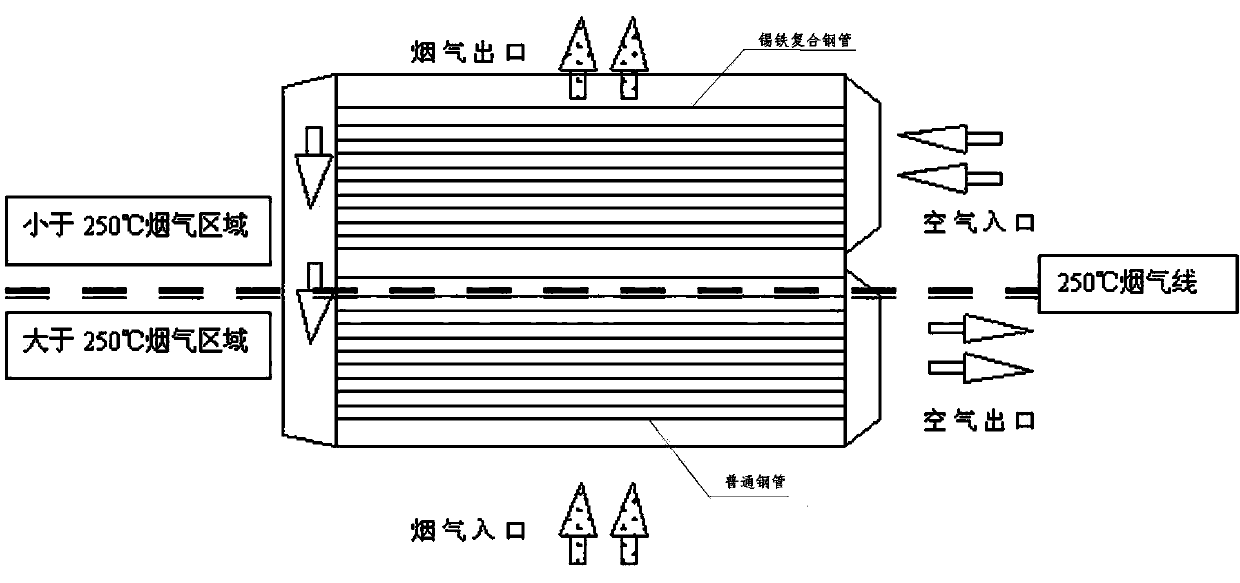

[0015] figure 1 It is the main structure diagram of the air preheater or economizer: the air pipe pass, the flue gas passes the shell pass, the part above the 250℃ temperature line inside the equipment is tin-iron composite steel pipe, and the rest are ordinary steel pipes;

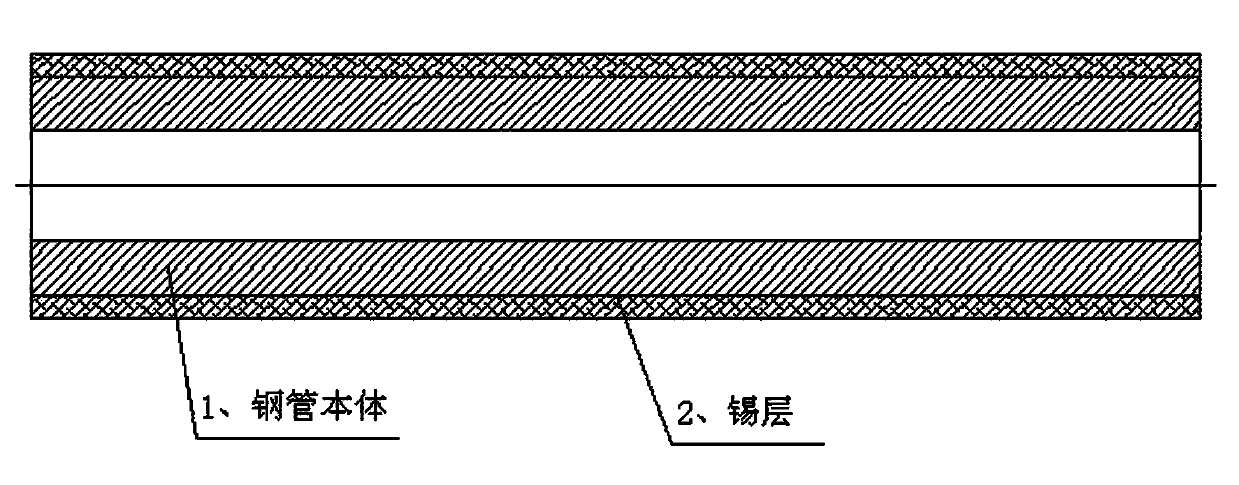

[0016] figure 2 It is a structural drawing of tin-iron composite steel pipe. The outer layer is a tin layer with a thickness of about 0.8-1.5mm, and the inner layer is a steel pipe, usually a seamless steel pipe, made of 45# steel with a thickness of 3-5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com