Optical Position Measuring Device

A measuring device and optical technology, applied in the direction of measuring device, using optical device, using optical device to transmit sensing components, etc., can solve the problems of using reflective integral measuring tools in the indexing period, and achieve the effect of high insensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

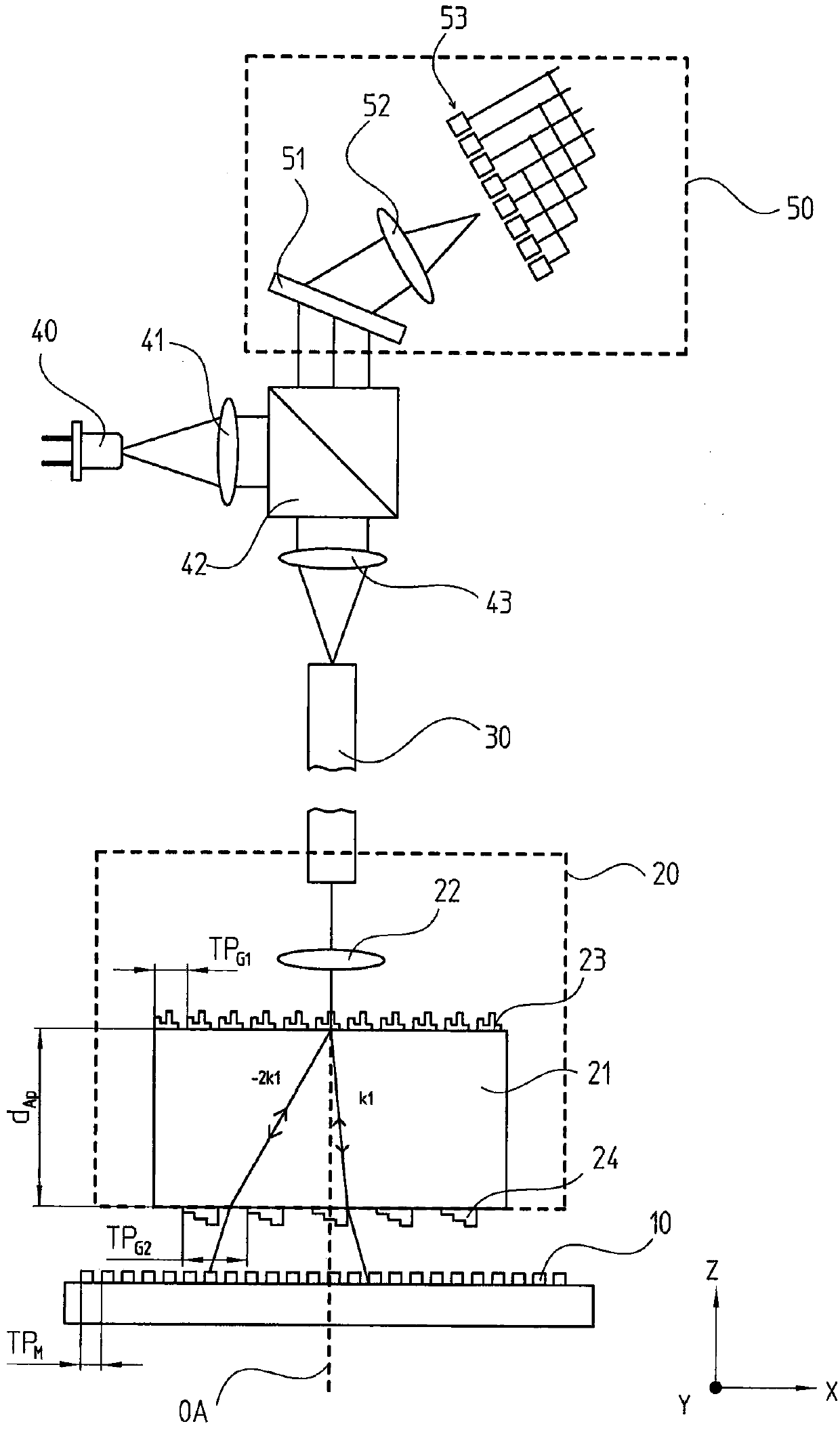

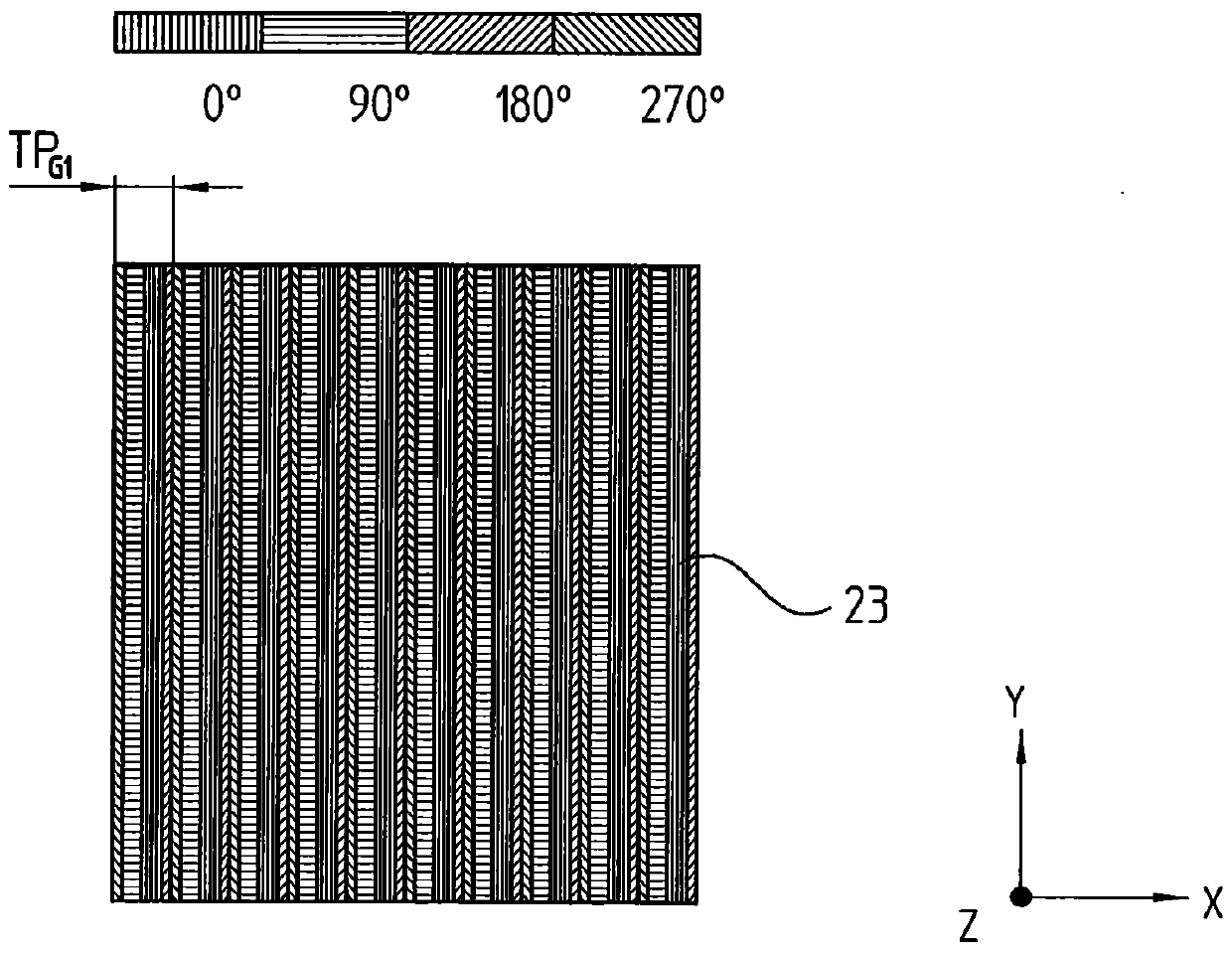

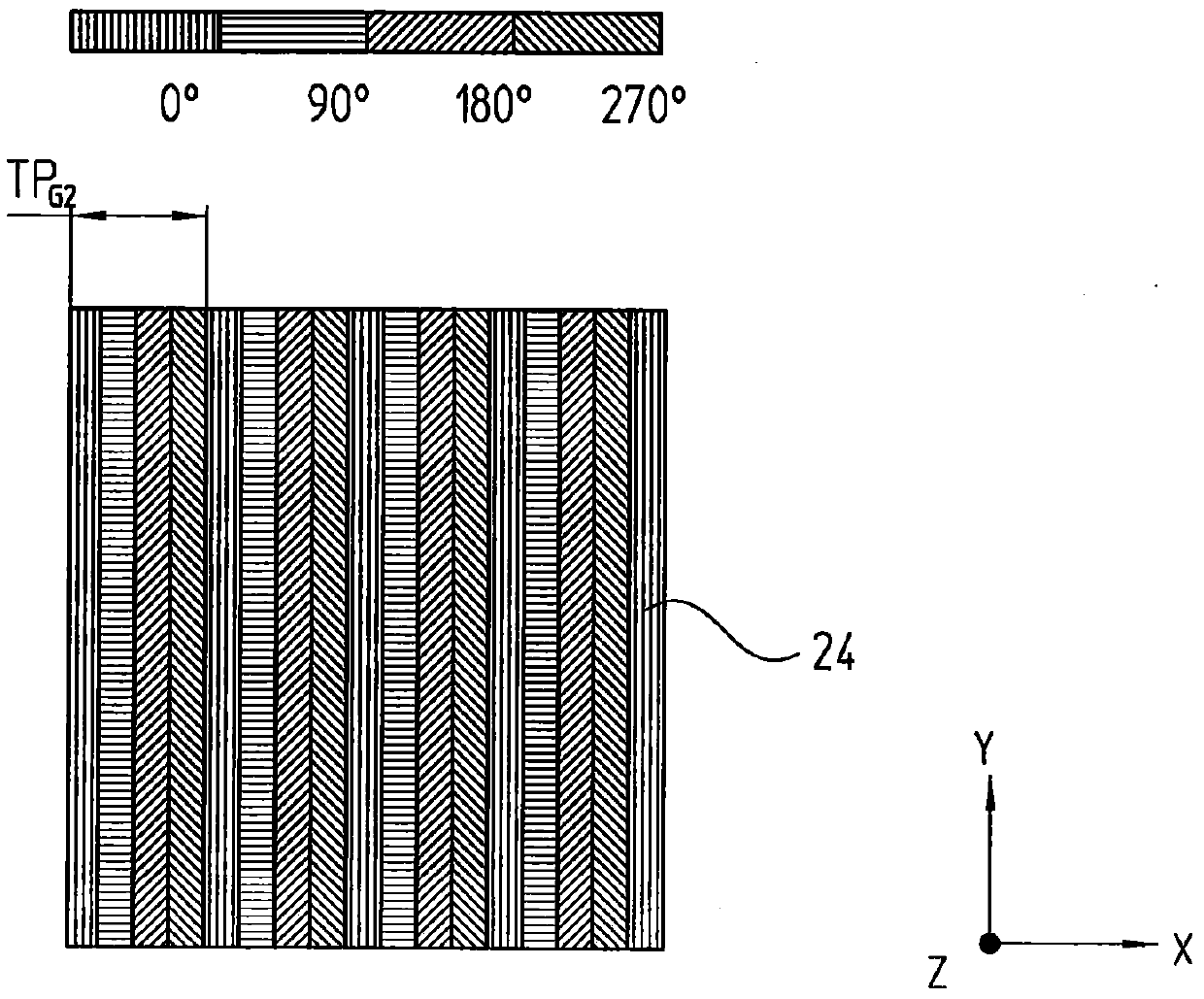

[0045] According to attached figure 1 , 2a and 2b A first embodiment of the position-measuring device according to the invention is explained below.

[0046]The optical position measuring device of the exemplary embodiment shown comprises a linear reflective measuring standard 10 which is arranged displaceably relative to a fiber optic scanning head 20 at least in a given measuring direction x. In this case, the reflective measuring standard 10 can be arranged stationary and the fiber optic scanning head 20 can be arranged movable or the reflective measuring standard 10 can be arranged movable and the fiber optic scanning head 20 can be arranged stationary. Reflective measuring standard 10 and fiber optic scanning head 20 are connected to two—not shown—objects which are movable relative to one another in measuring direction x and whose relative positions can be determined relative to one another. This involves two components of the machine that are movable relative to one ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com