Energy-saving running method suitable for OPGW (optical fiber composite overhead ground wire) cable of 220kV electric transmission line

A technology for transmission lines and operation methods, applied in the installation of optical fibers/cables, etc., can solve the problems of small resistance, power loss, and frequent broken strand faults in the outer layer of the optical cable, so as to achieve small power loss, reduce the probability of lightning strikes, The effect of reducing the difference in electrical performance of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

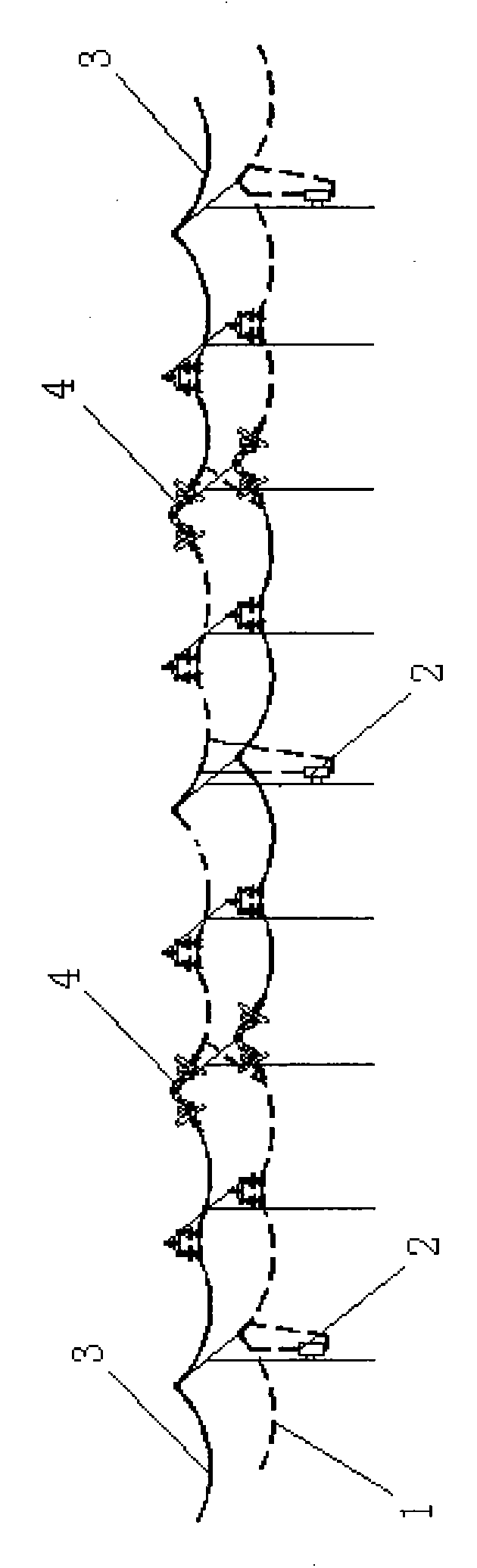

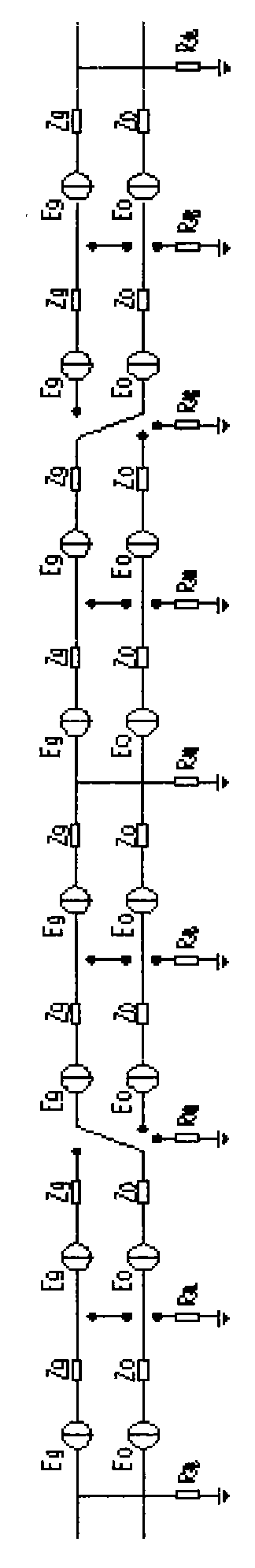

[0013] refer to Figure 1-2 In the present invention, the OPGW optical cable 1 is insulated from the straight tower through the ground wire insulator in the unit of the disk, and the connection point of each disk is used as the grounding point 2 to be grounded, and the whole line of the OPGW optical cable 1 is kept continuous. Transpose the OPGW optical cable 1 and the ground wire 3 on the tower 4, and fix the OPGW optical cable 1 with the OPGW optical cable insulation down-lead clamp at the transposition, so that the OPGW optical cable 1 and the tower head are kept insulated. Line 3 is directly grounded.

[0014] The grounding point 2 of the OPGW optical cable 1 of the present invention is selected at the joint of the optical cable, and the transposition point between the OPGW optical cable 1 and the ground wire 3 should be selected on any tension tower 4 other than the joint of the optical cable, and the insulating type optical cable is used to lead down the clamp The OPGW ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com