Method for simulating biaxial test of braided composite material and determining material performance parameters by using finite element method

A composite material and material performance technology, which is applied in the field of biaxial test parameter determination of braided composite materials, can solve problems such as large differences in data, and achieve the effects of simple operation, strong repeatability, and comprehensive mechanical response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

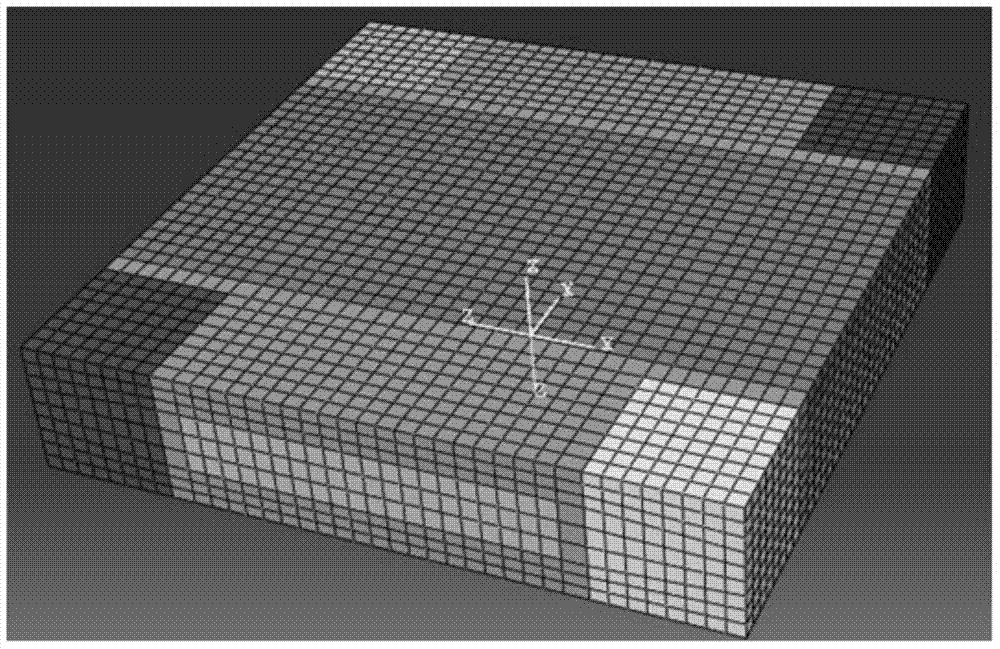

[0025] Specific Embodiment 1: This embodiment provides a method for simulating the biaxial test of braided composite materials to determine material performance parameters using the finite element method. This method needs to complete different forms of biaxial tests, and requires a polarizing microscope and a nanoindenter. The finite element software Abaqus and certain programming ability are required, which includes the following steps:

[0026] 1. Use a polarizing microscope to observe the braided composite material, use its periodicity to determine its smallest representative volume unit, and accurately measure the size and spatial distribution of the fiber bundles and matrix in several representative volume units , taking its average value;

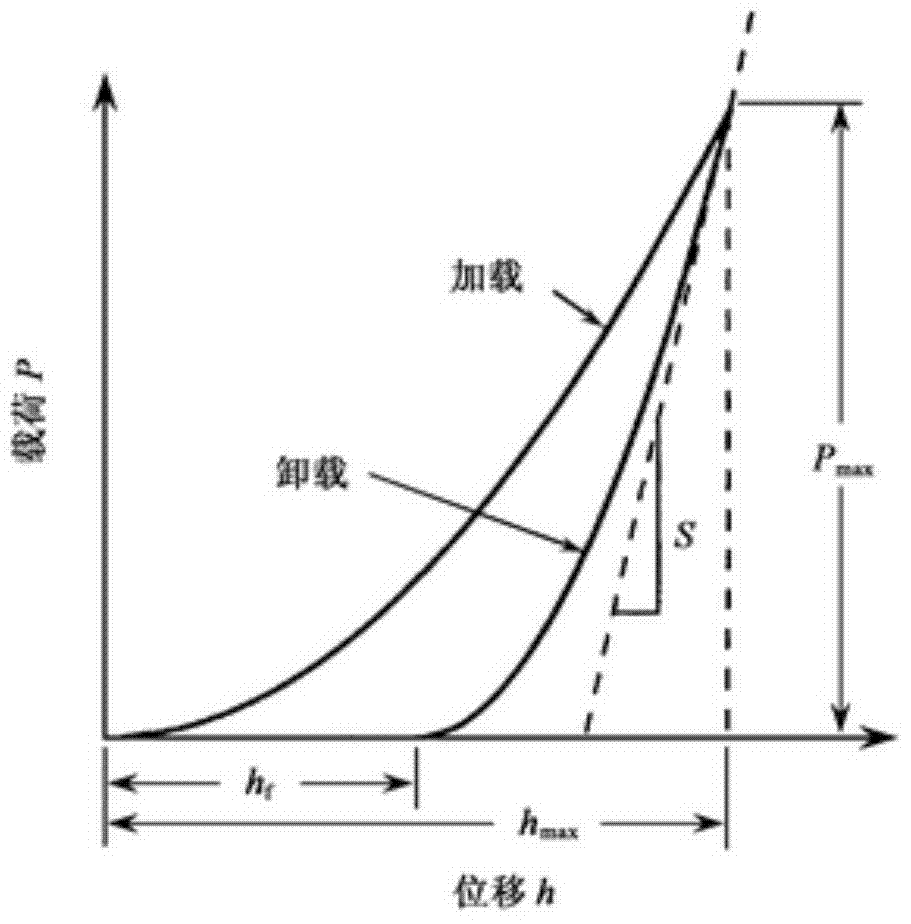

[0027] 2. After the braided composite material is roughly ground to the shape required by the nano-indenter, use nano-indentation technology to determine the transverse modulus E of the fiber bundle at different positions of the samp...

specific Embodiment approach 2

[0047] Specific implementation mode 2: In this implementation mode, a two-way compression experiment with a three-way orthogonal braided C / C composite material with a load ratio of 1:1 is taken as an example for specific description:

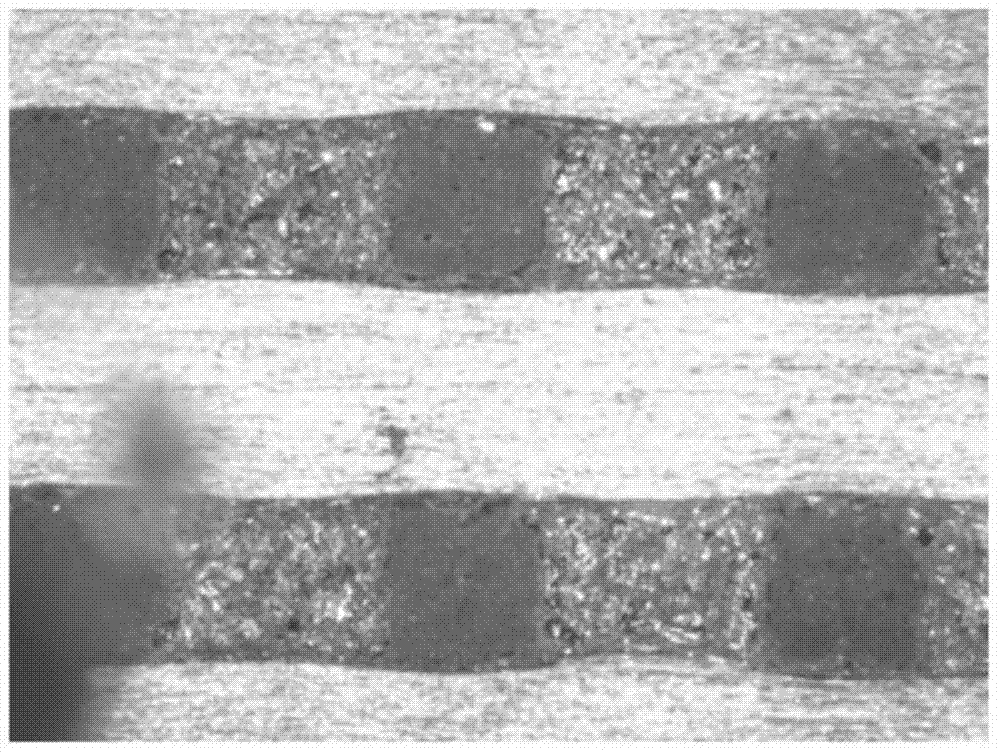

[0048] 1. Using a polarizing microscope to observe the internal microstructure of the material, it can be clearly observed that the fibers inside the material are regularly distributed, which are orthogonally distributed in the X, Y, and Z directions. The darkest area is the matrix. Carefully identify its periodicity and select Representative volume unit, and measure key dimension data within the volume unit, such as figure 1 shown;

[0049] 2. After grinding the material to the shape required by the nano-indenter, perform polishing treatment, and then conduct indentation tests on the fiber and the matrix on the nano-indenter in the direction perpendicular to the fiber bundle, and obtain a schematic diagram of the load-depth curve , according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com