Alkaline anion exchange membrane fuel cell failure membrane electrode recovery and regeneration method

An alkaline anion, fuel cell technology, applied in fuel cell parts, fuel cell disposal/recycling, fuel cell and other directions, to achieve the effect of simple method, extended running time and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

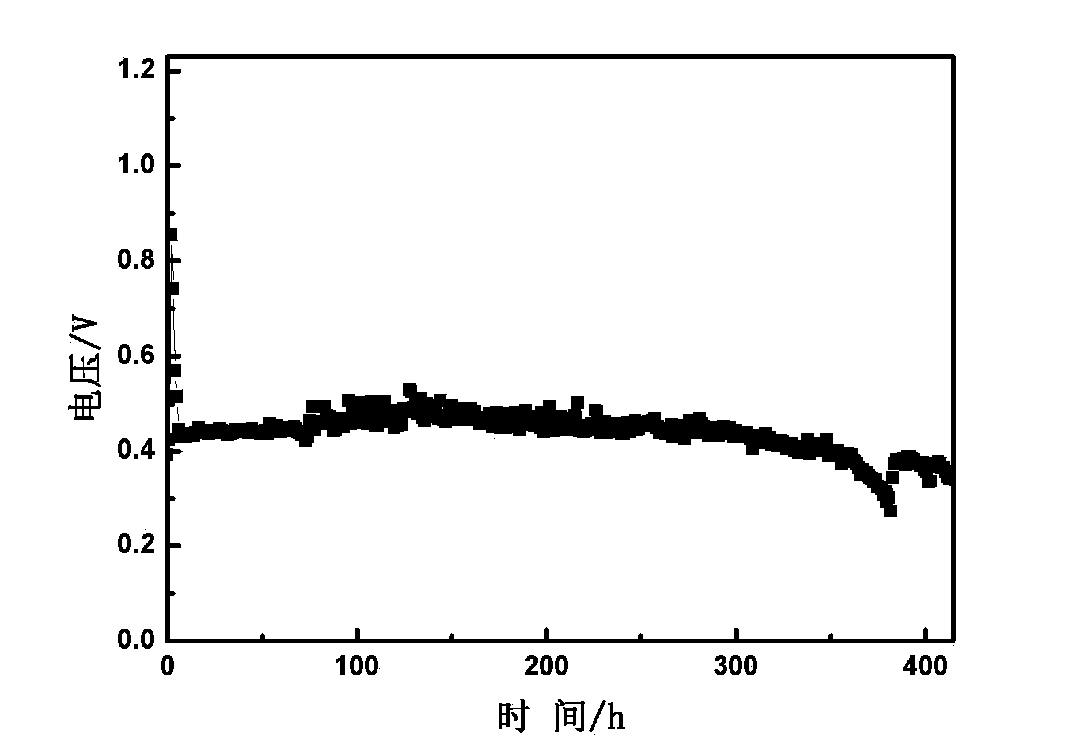

Embodiment 1

[0021] Constant current 100mA / cm under working temperature of 50°C and 100%RH humidification 2 For the alkaline anion exchange membrane electrode that fails after 383 hours of continuous operation, use 0.5mol / L potassium hydroxide (KOH) alkaline solution for anion exchange treatment for 1 hour to make the anion conduction of the alkaline anion exchange membrane and anion exchange resin The capacity is restored, and then rinsed repeatedly with deionized water for 3 to 5 times and soaked for 90 minutes to remove the residual lye on the surface. Finally, the treated membrane electrode was reassembled into the battery, and then operated under the aforementioned conditions. After the above-mentioned treatment method, the performance of the membrane electrode is restored and regenerated, and it can continue to operate. See figure 1 .

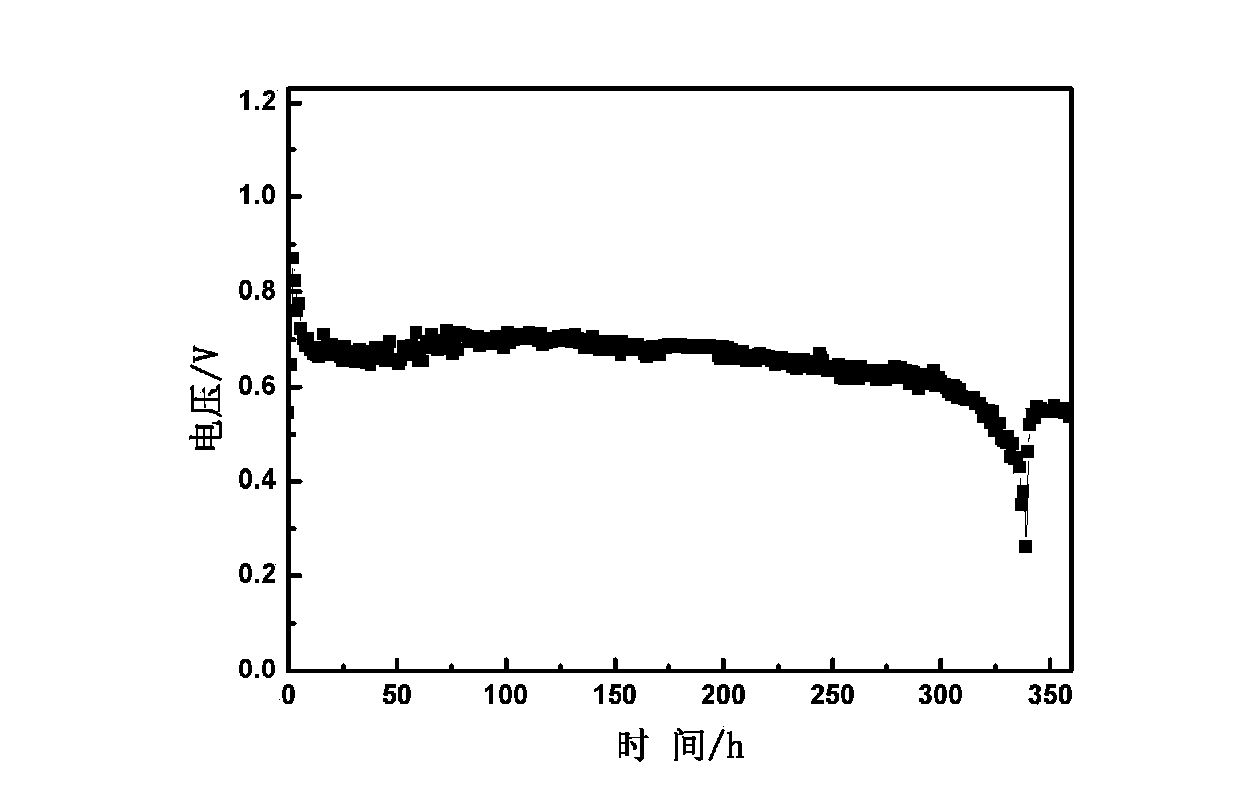

Embodiment 2

[0023] Constant current 100mA / cm under working temperature of 50°C and 100%RH humidification 2 For the alkaline anion exchange membrane electrode that fails after 339 hours of continuous operation, use 1mol / L potassium hydroxide (KOH) alkaline solution for anion exchange treatment for 0.5 hours to improve the anion conductivity of the alkaline anion exchange membrane and anion exchange resin. After being recovered, rinse repeatedly with deionized water for 3 to 5 times and soak for 120 minutes to remove the residual lye on the surface. Finally, reassemble the battery with the treated membrane electrode and operate it under the aforementioned conditions. With the aforementioned treatment method, the performance of the membrane electrode can be recovered and regenerated, and the operation can continue. See figure 2 .

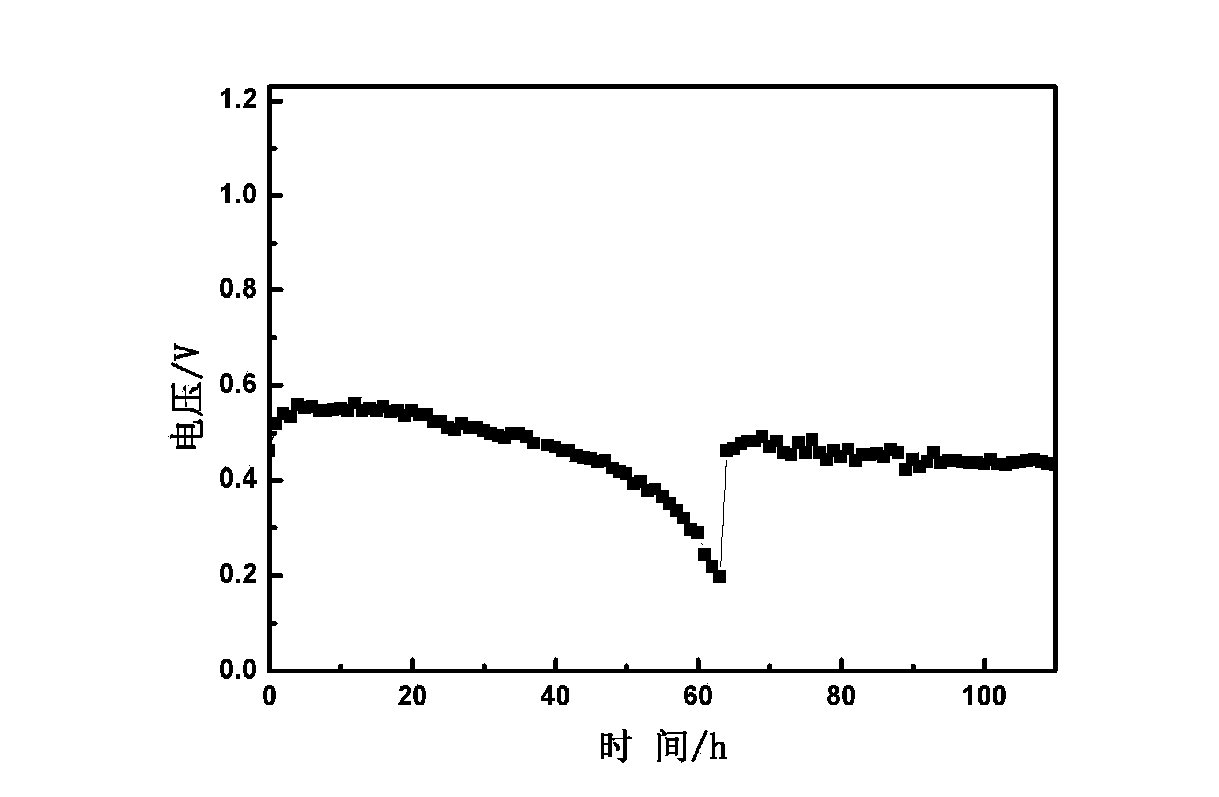

Embodiment 3

[0025] Constant current 100mA / cm under working temperature of 50°C and 100%RH humidification 2 The basic anion exchange membrane electrode that has been continuously operated for 64 hours is used for anion exchange treatment with 1mol / L sodium hydroxide (NaOH) alkaline solution for 0.5 hours, so that the anion conductivity of the alkaline anion exchange membrane and anion exchange resin can be improved. After recovery, rinse repeatedly with deionized water for 3 to 5 times and soak for 120 minutes to remove the residual lye on the surface. Finally, reassemble the battery with the treated membrane electrode and operate it under the aforementioned conditions. Treatment method, the performance of the membrane electrode is restored and regenerated, and can continue to operate. For the recovery of the battery voltage, see image 3 , see the impedance test results before and after treatment Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com