Novel integration technology of aquaculture facility

A technology of aquaculture and new technology, applied in fish farming, application, animal husbandry and other directions, can solve the problems of high cost, unsafe, long total wiring distance, etc., and achieve the effect of reducing energy consumption and increasing oxygen quantitatively.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

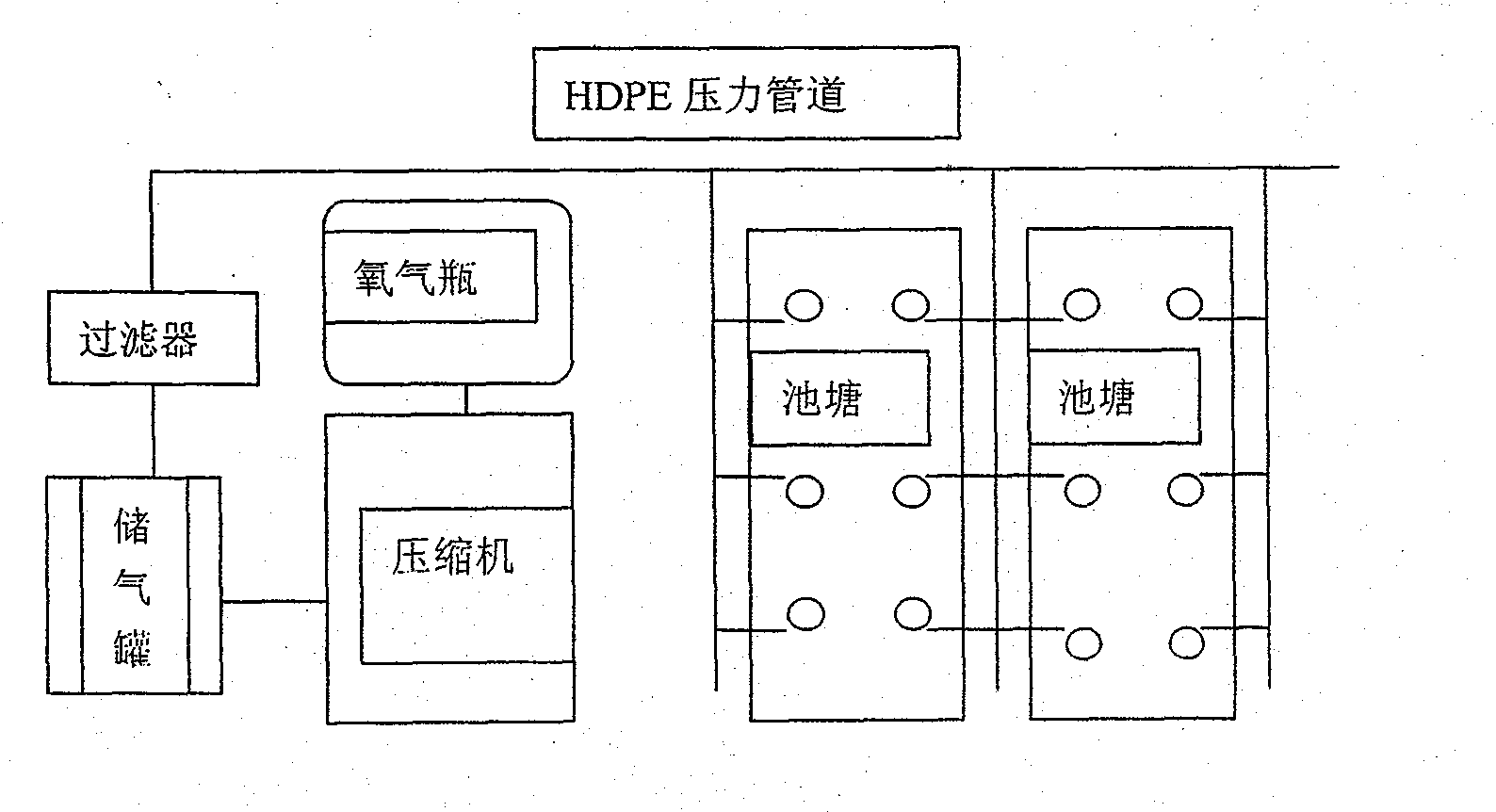

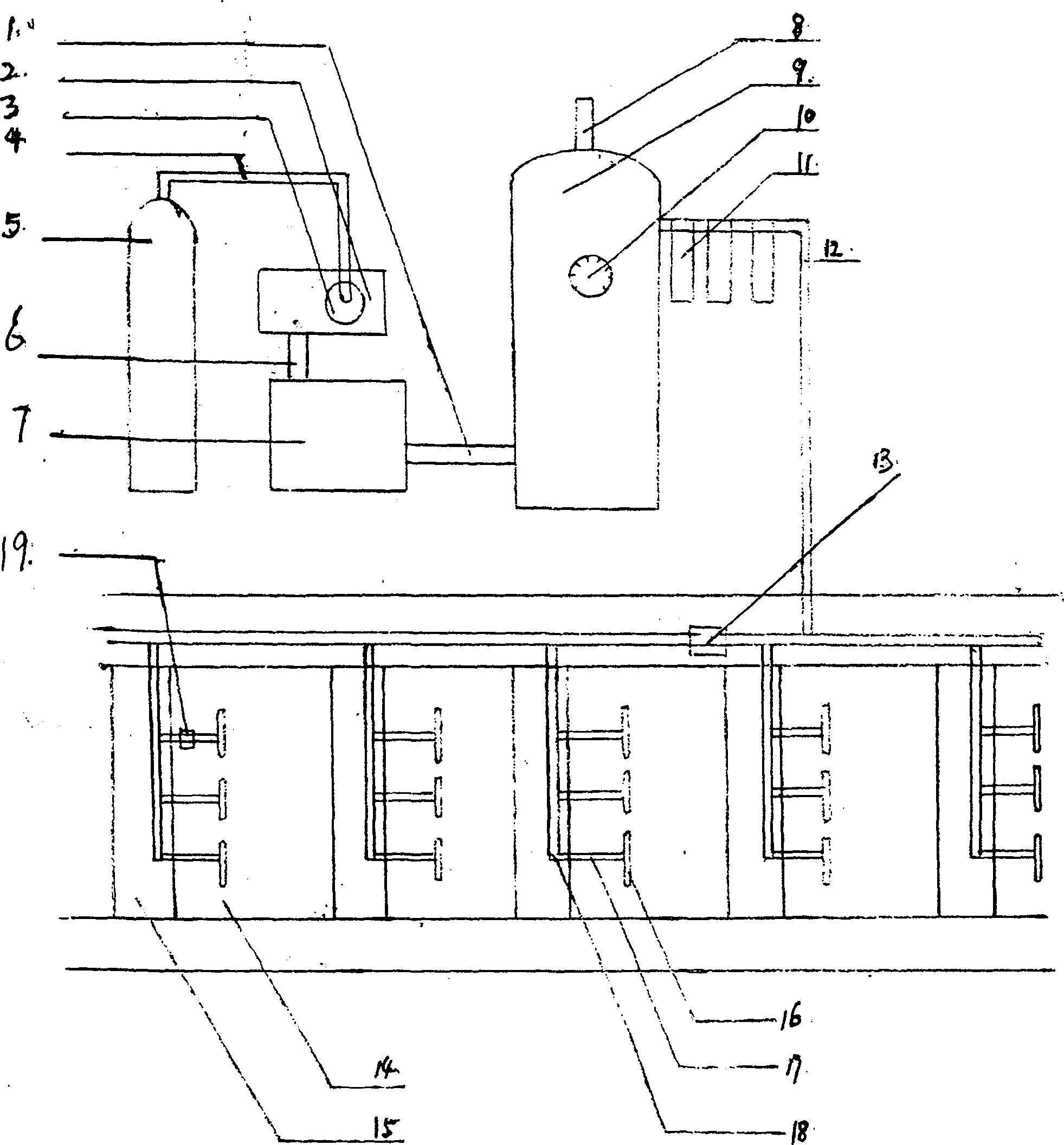

[0008] The implementation scheme of the new technology for aquaculture facilities integration of the present invention is to adopt a screw pump (screw air compressor) to match a high-pressure gas storage tank, add a pure oxygen cylinder, adjust the oxygen content of the supplied gas, and create a high-pressure gas source (0.8MPa), and the gas passes through The output of the three-stage air filter is filtered, and the high-density polyethylene (High Density Polyethylene, referred to as "HDPE" for short, with a pressure resistance of 1.6MPa) is applied to the high-pressure pipeline for long-distance oxygenation of multiple breeding ponds. One pond has multiple air heads. Installation, using the multi-head gas shunt technology, setting up the oxygen increasing head to promote the water circulation, realizing the uniform distribution of dissolved oxygen in the pond to achieve the effect of increasing oxygen, so that the aquaculture production can proceed smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com