Preparation method of ponkan dietary fiber

A dietary fiber and soluble dietary fiber technology, which is applied in food preparation, food drying, food extraction, etc., can solve the problems of discarding, unreported, and low comprehensive utilization rate of citrus peel residues, and achieves changing composition and structure, shortening Effect of extraction time, promotion of dissolution and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

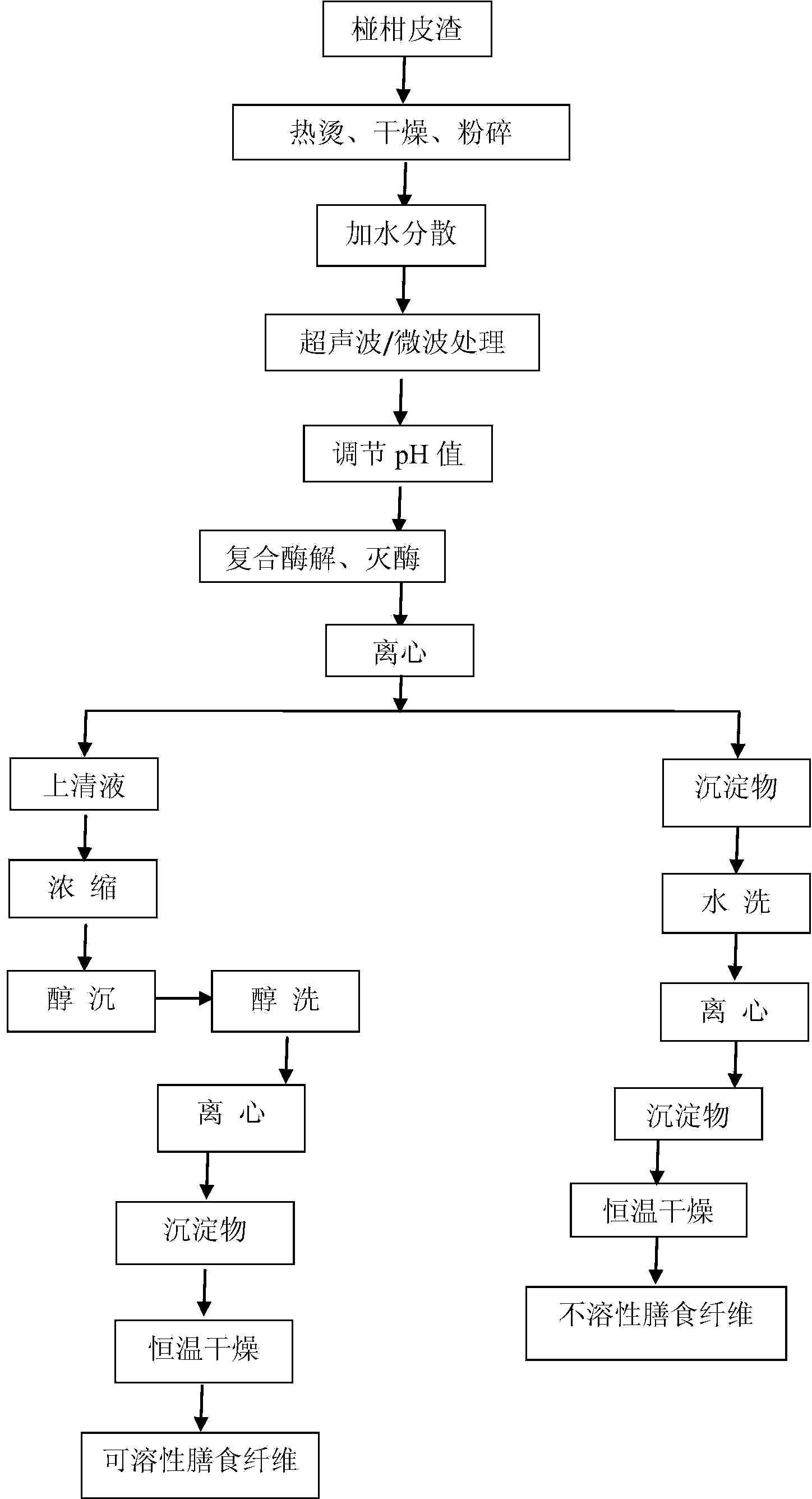

Method used

Image

Examples

Embodiment 1

[0040] (1) Pretreatment of raw materials: the ponkan peel residue obtained after the washed fresh ponkan fruit was squeezed was subjected to blanching treatment, the blanching temperature was 95° C., and the blanching time was 1.5 min. After blanching, the obtained ponkan peel residue was put into an electric constant temperature blast drying oven at 60°C for 36 hours to dry for 36 hours. The water content was 5%, and it was crushed to 80 mesh to obtain pretreated ponkan peel residue powder.

[0041] (2) Add water to disperse: add water to disperse the pulverized ponkan peel residue after step (1), the solid-to-liquid ratio is 1g: 3mL, stir evenly, and make a dispersion liquid;

[0042] (3) Ultrasonic-assisted water extraction: in step (2), the dispersion liquid is placed in an ultrasonic extraction device, the extraction temperature is 55°C, the solid-to-liquid ratio is 1g-15mL, the extraction time is 30min, and the ultrasonic power is 500W. The duty ratio is 1:2, extract twi...

Embodiment 2

[0052] (1) Pretreatment of raw materials: the ponkan peel residue obtained after the washed fresh ponkan fruit was squeezed for a blanching treatment, the blanching temperature was 90° C., and the blanching time was 2 minutes. After blanching, the obtained ponkan peel residue was put into an electric constant temperature blast drying oven at 60°C for 36 hours to dry for 36 hours. The water content was 5%, and it was crushed to 80 mesh to obtain pretreated ponkan peel residue powder.

[0053] (2) Add water to disperse: add water to disperse the pulverized ponkan peel residue after step (1), the solid-to-liquid ratio is 1g: 5mL, stir evenly, and make a dispersion liquid;

[0054] (3) Ultrasonic-assisted water extraction: in step (2), the dispersion liquid is placed in an ultrasonic extraction device, the extraction temperature is 70°C, the solid-to-liquid ratio is 1g-25mL, the extraction time is 40min, and the ultrasonic power is 450W. The duty ratio is 1:2, extract twice to obt...

Embodiment 3

[0064] (1) Pretreatment of raw materials: The ponkan peel residue obtained after the washed fresh ponkan fruit was squeezed was subjected to blanching treatment, the blanching temperature was 85° C., and the blanching time was 3 minutes. After blanching, the obtained ponkan peel residue was put into an electric constant temperature blast drying oven at 60°C for 36 hours to dry for 36 hours. The water content was 5%, and it was crushed to 80 mesh to obtain pretreated ponkan peel residue powder.

[0065] (2) Add water to disperse: add water to disperse the pulverized ponkan peel residue after step (1), the solid-to-liquid ratio is 1g: 4mL, stir evenly, and make a dispersion liquid;

[0066] (3) Microwave-assisted water extraction: in step (2), the dispersion liquid is placed in a microwave extraction device, the extraction temperature is 80°C, the solid-to-liquid ratio is 1g-15mL, the extraction time is 8min, and the microwave power is 650W. Extract 2 times to obtain the extract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Water holding capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com