Catalyst for ammonia synthesis and ammonia decomposition

A catalyst, ammonia decomposition technology, applied in the direction of physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, ammonia compound, etc., can solve problems such as inability to realize industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

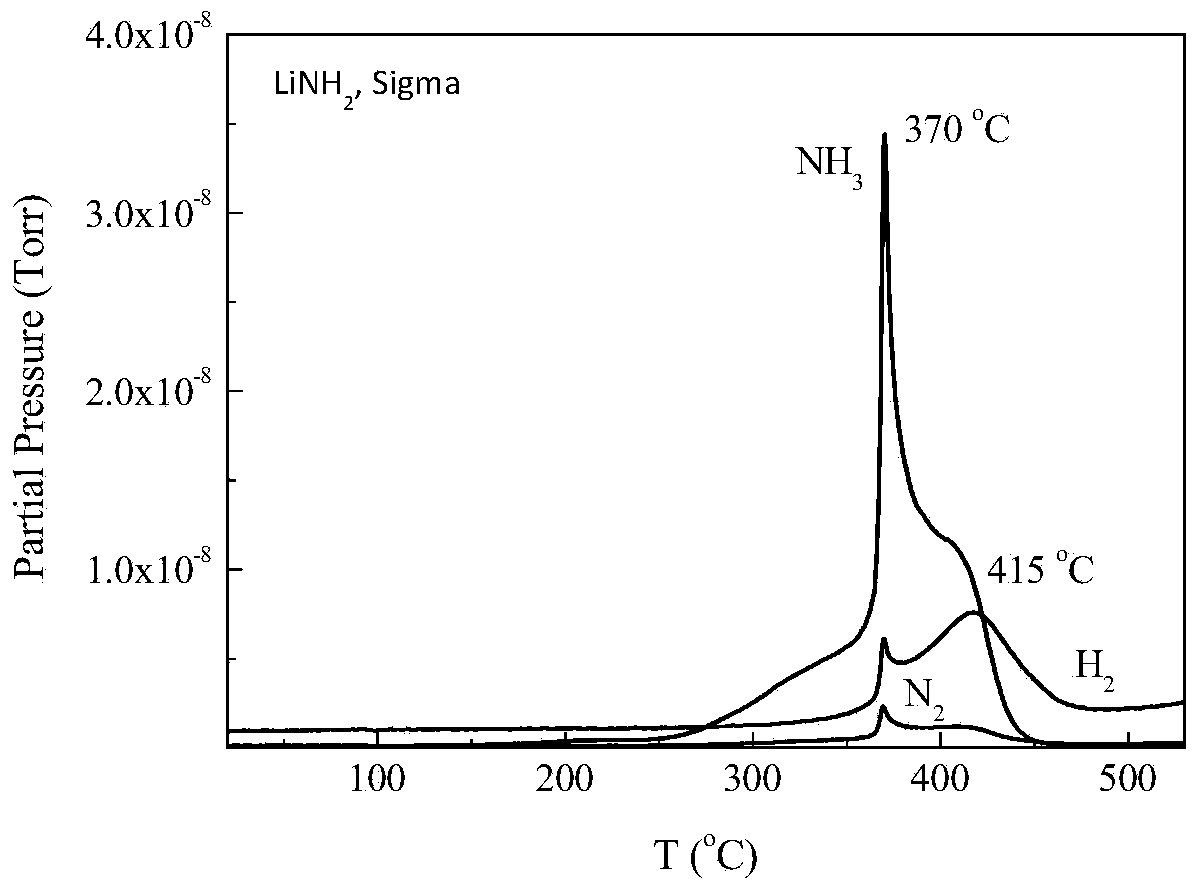

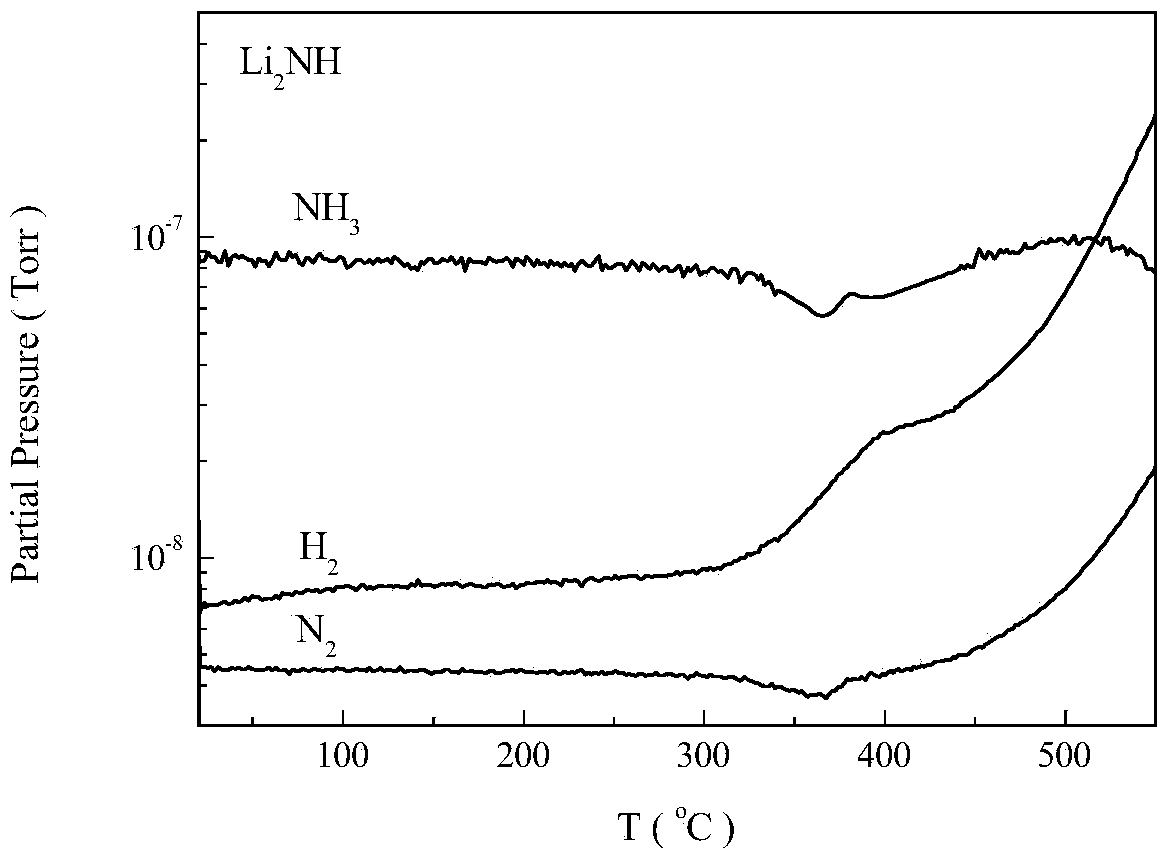

Image

Examples

Embodiment 1

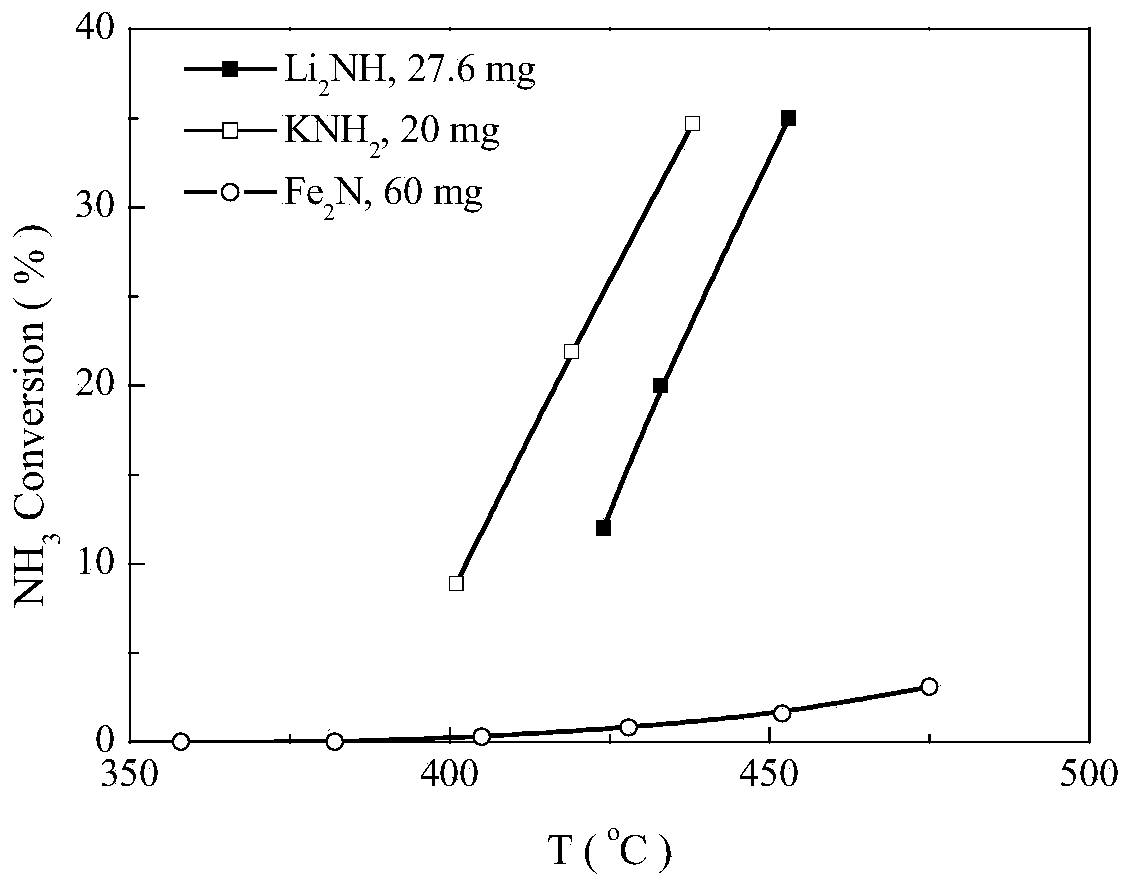

[0021] In an argon glove box, accurately weigh the lithium imide (Li 2 NH) 0.0300g, placed in a fixed-bed stainless steel reactor. The sample was heated to 400° C. in an argon atmosphere, and the argon flow rate was 30 mL / min. Cut into 5%NH after 20 minutes 3 / Ar mixed gas, the reaction gas flow rate was controlled at 1.8L / h and 3.6L / h, and samples were taken for analysis after 30 minutes. Test results such as image 3 shown. The conversion rate of ammonia gas increases approximately linearly with the increase of temperature, and the conversion rate of ammonia gas reaches 35% at 450 degrees.

Embodiment 2

[0023] In an argon glove box, accurately weigh potassium amide (KNH 2 ) 0.0300g, placed in a fixed-bed stainless steel reactor. The sample is heated to 400 degrees in an argon atmosphere, and cut into 5% NH after 20 minutes 3 / Ar mixed gas, the reaction gas flow rate was controlled at 1.8L / h and 3.6L / h, and samples were taken for analysis after 30 minutes. Test results such as image 3 shown. The ammonia conversion rate increases approximately linearly with the increase of temperature. At the same reaction temperature, its activity is slightly higher than that of lithium imide, and the conversion rate of ammonia can reach 35% at 440 degrees.

Embodiment 3

[0025] In an argon glove box, accurately weigh iron nitride (Fe 2 N) 1.0000g, and lithium amide (LiNH 2) 0.7300g, placed in a self-made stainless steel ball mill jar. After closing the ball milling tank, put it into a planetary ball mill (Fischt PM400), and the ball milling condition is 200rpm ball milling for 5 hours. The obtained sample Fe 2 N / LiNH 2 (molar ratio 0.5:2).

[0026] In an argon glove box, accurately weigh Fe 2 N / LiNH 2 (Molar ratio 0.5:2) 0.0350g, placed in a fixed-bed stainless steel reactor. The sample was in a reaction atmosphere (5%NH 3 / Ar mixed gas) to the desired temperature, the reaction gas flow rate was controlled at 1.8L / h and 3.6L / h, and samples were taken for analysis after 30 minutes. Test results such as Figure 4 shown. The conversion rate of ammonia gas increases gradually with the increase of temperature. When the temperature is 380 degrees, the conversion rate of ammonia gas can reach 22%. When the temperature is higher than 380 deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com