A kind of high stiffness and thermal insulation food packaging film processing method and its product

A technology of food packaging film and processing method, applied in transportation and packaging, chemical instruments and methods, packaging, etc., can solve the problems of heat insulation, poor sealing, damage to packaging film, short shelf life, etc. Excellent performance, enhanced overall strength, and clear display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

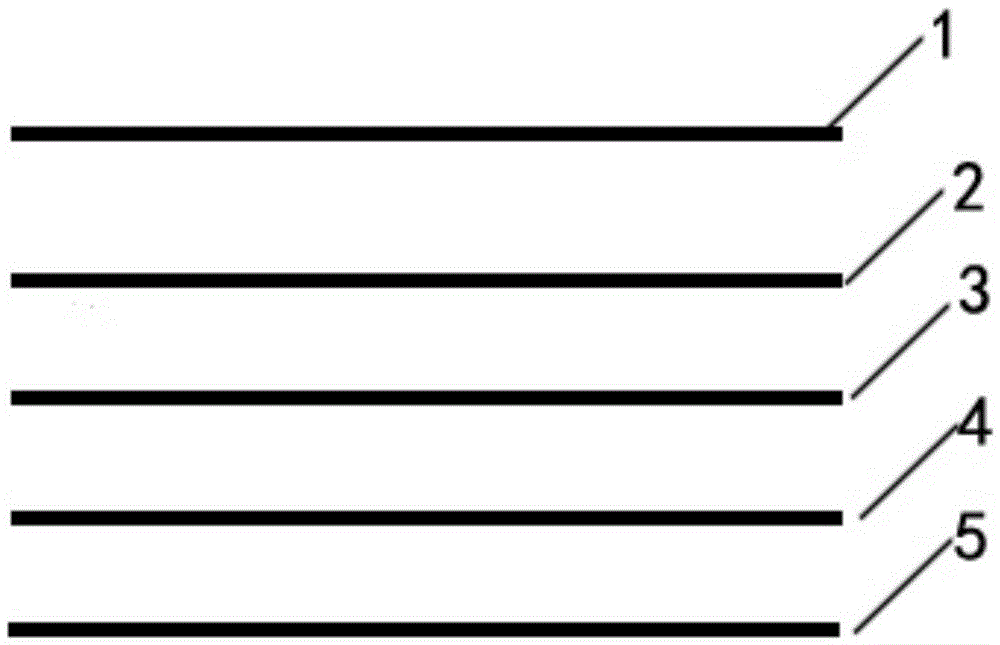

[0026] The high-stiffness heat-insulating food packaging film includes the following composite layers, and the following composite layers are processed into a high-stiffness heat-insulating food packaging film through upper and lower double-roll extrusion, wherein the upper and lower double-roll extrusion The control nip pressure in the composite area is 100-120kN / m; the hot air drying temperature in the rear section is 60-80°C, and the moisture in the drying area is controlled to be 9-15% relative to the total mass of the packaging film. The composite layers of each layer are, see figure 1 :

[0027] (1) The first layer of composite layer 1, choose corona pretreatment, the thickness is 12-18μm PET film, the bottom surface of the PET film is printed with patterns and sizing, the sizing amount is 8-10g / m 2 , the curing amount is 3-5g / m 2 ;

[0028] (2) The second layer of composite layer 2, choose food grade wrapping paper, food grade wrapping paper quantitative 40-60g / m 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com