A kind of active calcium phosphate production method capable of continuous operation

A technology of activated calcium phosphate and its production method, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as low labor efficiency, low activity, and difficulty in controlling product particle size, and achieve the effect of controllable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

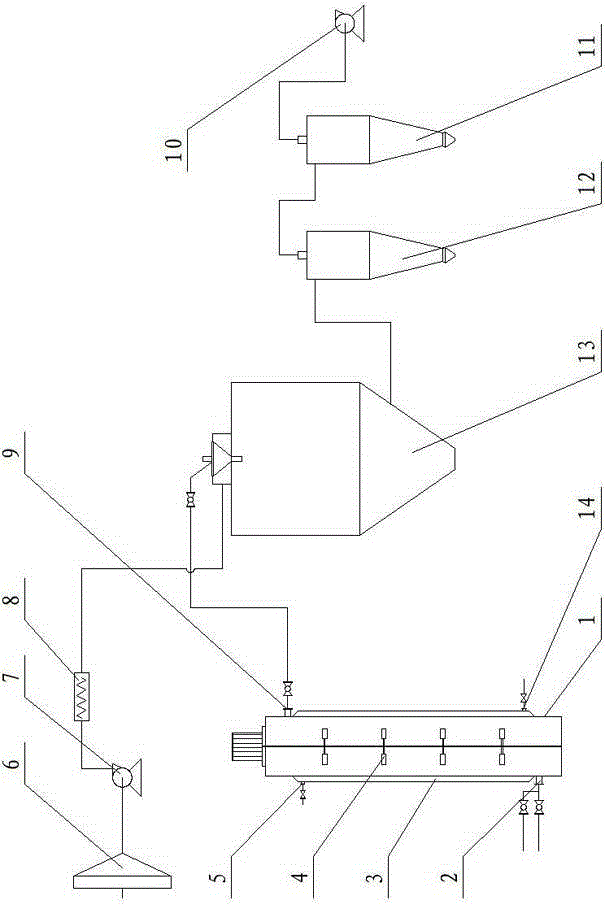

[0027] A method for continuously operating active calcium phosphate production, comprising the following production steps, (1) preparation of raw materials: Ca(OH) with a mass percentage content greater than or equal to 98% 2 Add water and mix according to the ratio of 0.7-0.8:1, and prepare Ca(OH) with a concentration of 40%-45%. 2 Slurry; (2) Reaction: adopt the tubular reactor 1 with stirring to carry out continuous production, and the above-mentioned Ca(OH) 2 Slurry and phosphoric acid with a concentration of 65% are continuously and uninterruptedly added to the inside of tubular reactor 1 in a ratio of 1.8:1 by mass ratio, and the feed flow rate is adjusted so that Ca(OH) 2The residence time of the slurry and phosphoric acid in the tubular reactor is controlled between 15 and 20 minutes. At the same time, the reaction temperature in the tubular reactor 1 is controlled to be 50°C-60°C, the pressure is 1-2MP, and the pH is 7 ~8, and the neutralization reaction is carried o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com