Preparation method of narrow molecular weight distribution polysiloxane

A technology of narrow molecular weight distribution and polysiloxane, which is applied in the field of preparation of narrow molecular weight distribution polysiloxane and narrow molecular weight distribution polysiloxane, which can solve the problems of wide molecular weight distribution and achieve adjustable reaction temperature and short reaction time. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of the narrow molecular weight distribution polysiloxane in the embodiment of the present invention, its step is: add VD to the ampule bottle of 20ml 3 Monomer 1.6ml solvent monomer, then add 1.4ml of freshly distilled tetrahydrofuran, stir for about 20min, keep the temperature in an ice-water bath at a constant temperature, add 0.46ml of n-butyllithium solution, and after the predetermined reaction time is reached, precipitate out the polymer with anhydrous ice methanol things.

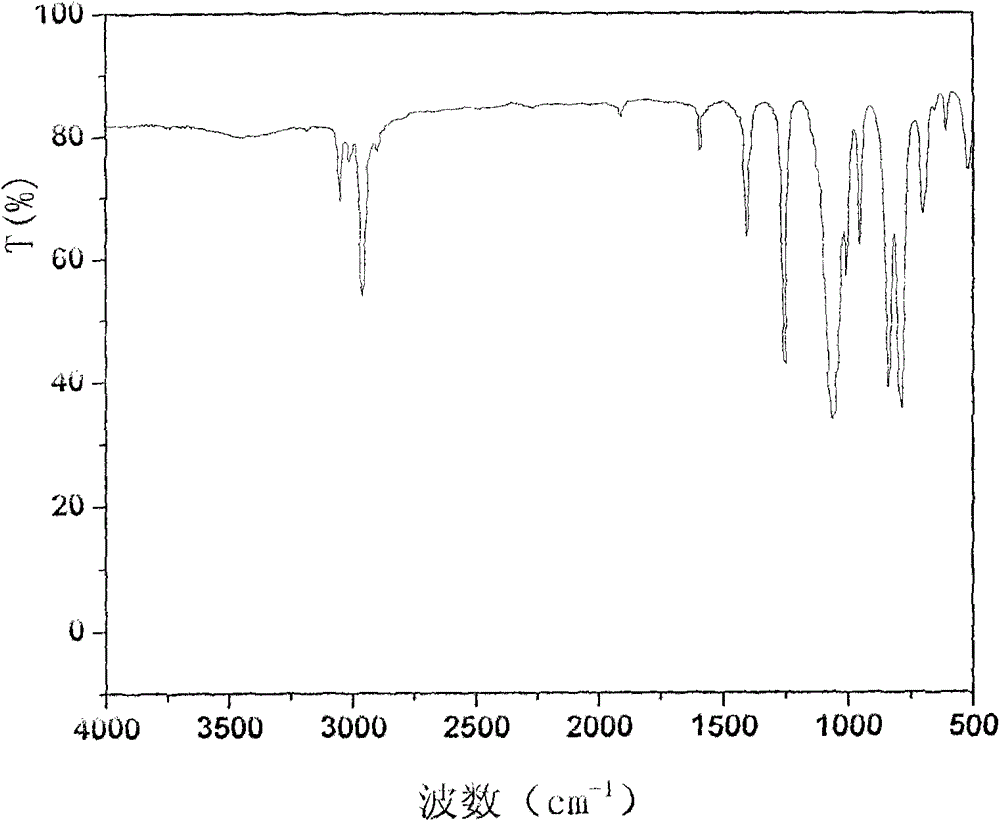

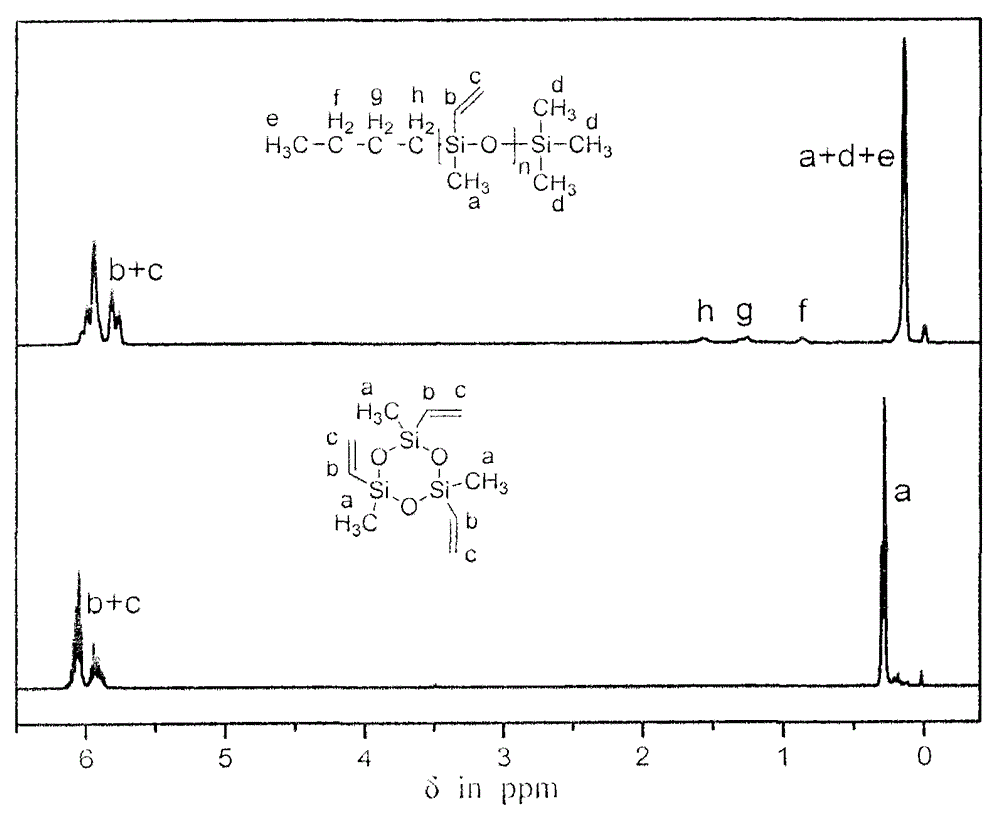

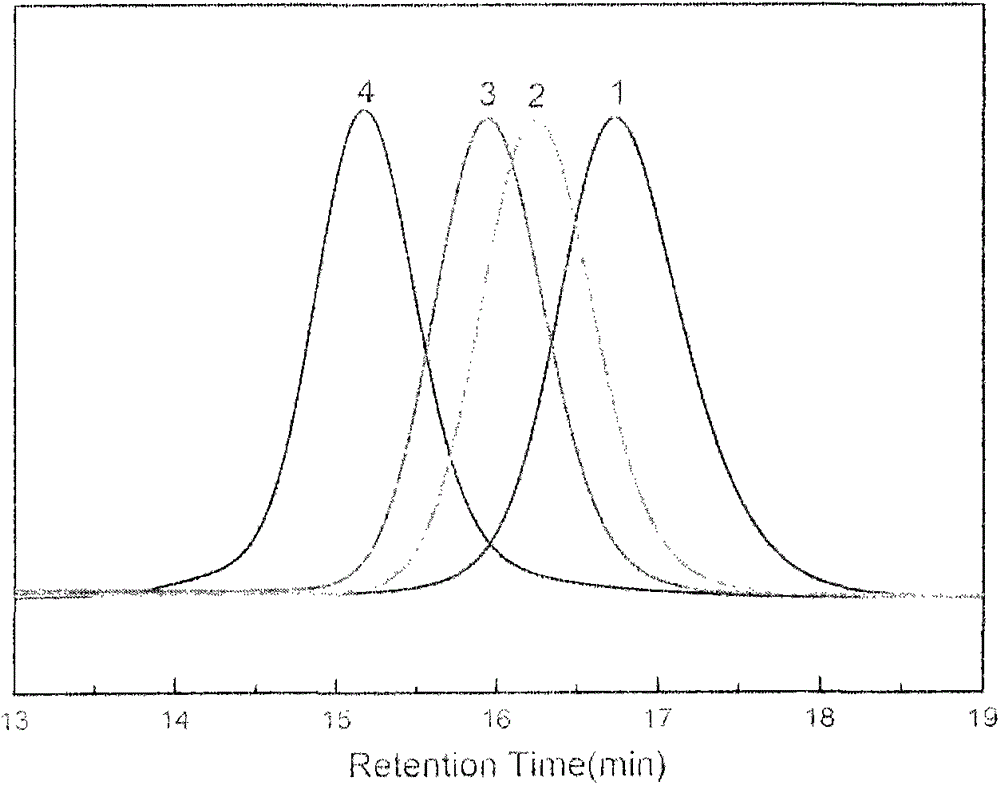

[0021] figure 1 It is the FT-IR spectrum of the narrow molecular weight distribution polysiloxane in Example 1 of the present invention. figure 2 It is the NMR image of the narrow molecular weight distribution polysiloxane in Example 1 of the present invention. image 3 The curve marked as 1 is the GPC / RI diagram of the narrow molecular weight distribution polysiloxane in the examples of the present invention. Figure 4 The curve marked as 1 in the middle is the GPC / ...

Embodiment 2

[0024] The preparation method of the narrow molecular weight distribution polysiloxane in the embodiment of the present invention, its step is: add VD to the ampule bottle of 20ml 3 Monomer 1.6ml solvent monomer, then add 1.4ml freshly distilled tetrahydrofuran, stir for about 20min, keep the temperature in an ice-water bath at a constant temperature, add 0.31ml of n-butyllithium solution, after the predetermined reaction time is reached, precipitate out the polymer with anhydrous ice methanol things.

[0025] image 3 The curve marked as 2 is the GPC / R1 graph of the narrow molecular weight distribution polysiloxane in the examples of the present invention. Figure 4 The curve marked as 2 in the middle is the GPC / LS chart of the narrow molecular weight distribution polysiloxane in the embodiment of the present invention.

[0026] After testing, the prepared polysiloxane has a molecular weight of 10000 and a distribution of 1.06.

Embodiment 3

[0028] The preparation method of the narrow molecular weight distribution polysiloxane in the embodiment of the present invention, its step is: add VD to the ampule bottle of 20ml 3 Monomer 1.6ml solvent monomer, then add 1.4ml freshly distilled tetrahydrofuran, stir for about 20min, keep the temperature in an ice-water bath at a constant temperature, add 0.25ml of n-butyllithium solution, after the predetermined reaction time is reached, precipitate out the polymer with anhydrous ice methanol thing.

[0029] image 3 The curve marked as 3 is the GPC / RI diagram of the narrow molecular weight distribution polysiloxane in the examples of the present invention. Figure 4 The curve marked as 3 is the GPC / LS chart of the narrow molecular weight distribution polysiloxane in the examples of the present invention.

[0030] After testing, the molecular weight of the prepared polysiloxane was 15000, and the distribution was 1.09.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com