Non-ionic surfactant and preparation method and application thereof

A technology of non-ionic surface and active agent, applied in the field of non-ionic surface active agent and its preparation, can solve the problem that the low temperature performance of asphalt affects the large-scale transformation of mixing equipment, etc. The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh myristic acid (0.05mol) and polyetheramine (0.06mol) with a molecular weight of 230 in a flask, and add xylene as a solvent. React at 140-160°C for 10-18 hours, and monitor the reaction by titrating the primary amine value. During the reaction process, water separator was used to remove the water in the reaction process. After the reaction was over, water and xylene were distilled off under reduced pressure to obtain compound 14A, and the number of carbon atoms in the saturated fatty acid was changed (the number of carbon atoms was 8, 10, and so on). , 12, 16, 18), to obtain compounds 8A, 10A, 12A, 16A, 18A, respectively.

[0031]

Embodiment 2

[0033] Weigh oleic acid (0.05mol) and polyetheramine (0.06mol) with a molecular weight of 230 in a flask, and add xylene as a solvent. React at 140-160°C for 10-18 hours, and monitor the reaction by titrating the primary amine value. During the reaction, a water separator was used to remove the water in the reaction process. After the reaction, the water and xylene were distilled off under reduced pressure to obtain compound 18a.

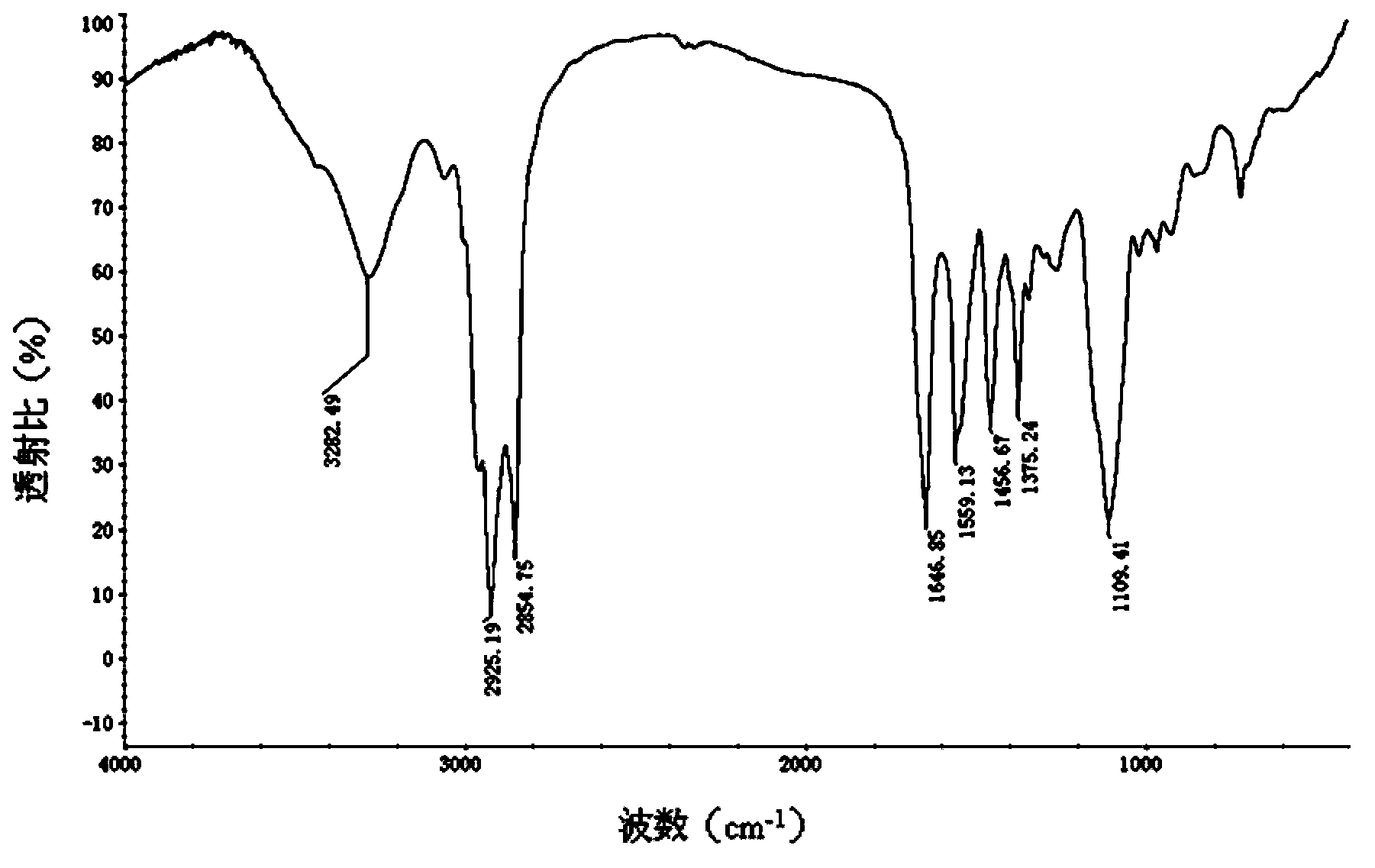

[0034] Further confirmed by infrared spectrum, the infrared spectrum of 18a is as follows figure 1 shown. figure 1 Medium wave number 3282cm -1 is the terminal amino group in 18a (-NH 2 ) and the carbon-hydrogen (-C=C-H) stretching vibration absorption peak on the carbon-carbon double construction, the wave number is 2925cm -1 It is the C-H stretching vibration absorption peak of the methyl group, with a wave number of 2854cm -1 It is the C-H stretching vibration absorption peak of methylene, with a wave number of 1646cm -1 It is the carbonyl ...

Embodiment 3

[0037] Weigh myristic acid (0.05mol) and polyetheramine (0.06mol) with a molecular weight of 400 in a flask, and add xylene as a solvent. React at 140-160°C for 10-18 hours, and monitor the reaction by titrating the primary amine value. During the reaction, a water separator was used to remove the water in the reaction process. After the reaction, the water and xylene were distilled off under reduced pressure to obtain compound 14B. By changing the number of carbon atoms in the saturated fatty acid (the number of carbon atoms is 8, 10, 12, 16, 18 in sequence), compounds 8B, 10B, 12B, 16B, and 18B were obtained respectively.

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com