Method for sealing tenon on instrument shell

A tenon and shell technology, applied in the field of instrument shell sealing, can solve problems such as difficult operation, loss of protection function, and high labor intensity, and achieve the effect of simple coating construction operation, saving time and cost, and prolonging the protection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

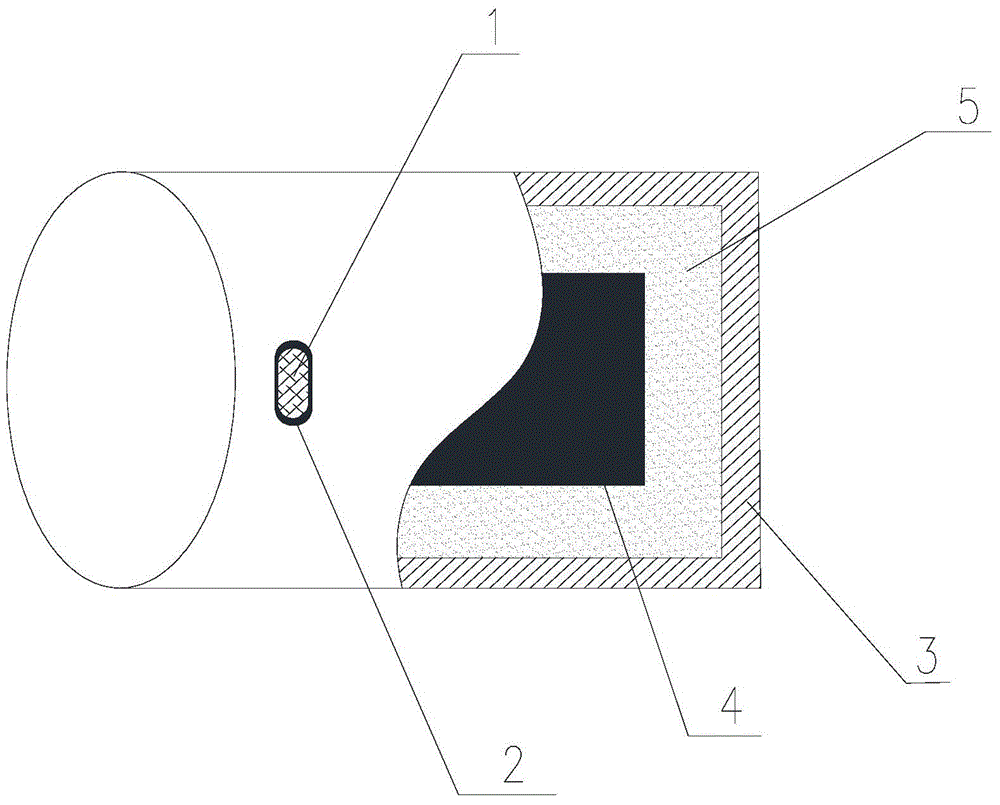

[0020] Attached below figure 1 An embodiment of the present invention is described.

[0021] A method for sealing a tenon on an instrument housing, comprising the following steps:

[0022] 1) Put the shell 3 flat before applying the glue, so that the inner plate of the tenon 1 is vertically upward;

[0023] 2) Use a knife or a needle to carefully clean the remaining paraffin wax 5 or other pollutants at the gap 2 around the tenon 1;

[0024] 3) Use a hair dryer to blow at the 2 gaps around the tenon 1, so that the residual wax in the 2 gaps flows back into the shell 3, and then use a cotton cloth dipped in gasoline to repeatedly scrub the flowed residual wax 2 to 3 times until it is clean;

[0025] 4) When applying the glue, first tie or cut a small hole in the mouth of the rubber tube, apply the glue to the gap 2 along the tenon 1, and drive the glue silted around the gap 2 of the tenon 1 to the gap 2; The glue is a quick-drying adhesive with α-ethyl cyanoacrylate as the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com