Preparation method of remediation flora for Cr (VI) contaminated site from sludge

A site remediation and sludge technology, applied in the restoration of polluted soil, biochemical equipment and methods, microorganisms, etc., can solve the problems of high cultivation cost of remediation bacteria, difficulty in adapting to the surrounding environment, low treatment efficiency, etc. Environmental and economic benefits, strong tolerance, complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

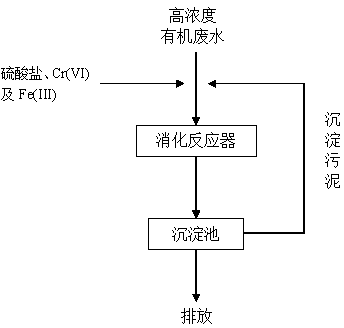

[0020] The flow chart of bacterial culture is as follows: figure 1 As shown, the specific cultivation is divided into start-up phase, domestication phase and continuous cultivation phase, the steps are as follows:

[0021] (1) In the start-up phase, mix digested sludge, facultative tank sludge and high-concentration organic wastewater at a ratio of 1:0.2:10, and add a certain amount of sulfate, Cr(VI) and Fe(III) at the same time to make the above The concentrations of the three in the mixture are: 200 mg / L (sulfate), 10 mg / L (Cr(VI)) and 5mg / L (Fe(III)). Put the above mixed liquid into the digestion reactor, stir continuously to make it evenly mixed, and at the same time, lead out the generated waste gas for discharge. After reacting the mixed liquid in the digestion reactor for 3 days, discharge 2 / 3 of the digestion liquid in the reactor and send it to the sedimentation tank; after the discharged digestion liquid is still in the sedimentation tank for 30 minutes, discharge ...

example 2

[0028] The flow chart of bacterial culture is as follows: figure 1 As shown, the specific cultivation is divided into start-up phase, domestication phase and continuous cultivation phase, the steps are as follows:

[0029] (1) In the start-up phase, mix digested sludge, facultative tank sludge and high-concentration organic wastewater at a ratio of 1:0.5:15, and add a certain amount of sulfate, Cr(VI) and Fe(III) at the same time to make the above The concentrations of the three in the mixture are: 200 mg / L (sulfate), 10 mg / L (Cr(VI)) and 5mg / L (Fe(III)). Put the above mixed liquid into the digestion reactor, stir continuously to make it evenly mixed, and at the same time, lead out the generated waste gas for discharge. After reacting the mixed liquid in the digestion reactor for 2 days, discharge 1 / 2 of the digestion liquid in the reactor and send it to the sedimentation tank; after the discharged digestion liquid is still in the sedimentation tank for 30 minutes, discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com