A vanadium-containing iron water extraction vanadium dephosphorization agent

A technology of vanadium dephosphorization agent and dephosphorization agent, which is applied in vanadium-containing molten iron vanadium extraction dephosphorization agent, molten iron vanadium extraction dephosphorization field, can solve the problems of reduced vanadium extraction rate, high melting point of lime, serious temperature drop, etc., and achieve high Vanadium extraction rate and dephosphorization rate, effect of reducing dephosphorization load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation of the vanadium-containing hot metal extracting vanadium dephosphorization agent in the present invention involves the crushing and drying of raw materials, the preparation of the dephosphorizing agent and the vanadium extracting agent, and the preparation of the dephosphorizing agent to obtain a calcium ferrite dephosphorizing agent and a calcium ferrite dephosphorizing agent. Mixed with vanadium extractor. Each link will be described in detail below in the order of preparation.

[0016] 1. Selection and crushing of raw materials. Since the chemical components and proportions of the dephosphorization agent in the present invention are, Fe 2 O 3 45~55wt%, CaO35~47wt%, Al 2 O 3 2~5wt%, SiO 2 2 O 3 50~70wt%, Al 2 O 3 5~10wt%, SiO 2 5-20wt%, MgO5-15wt%; of course, these all contain appropriate amount of impurities, among which Al 2 O 3 All are flux. Therefore, the raw materials constituting the dephosphorization agent of the present invention ar...

example 1

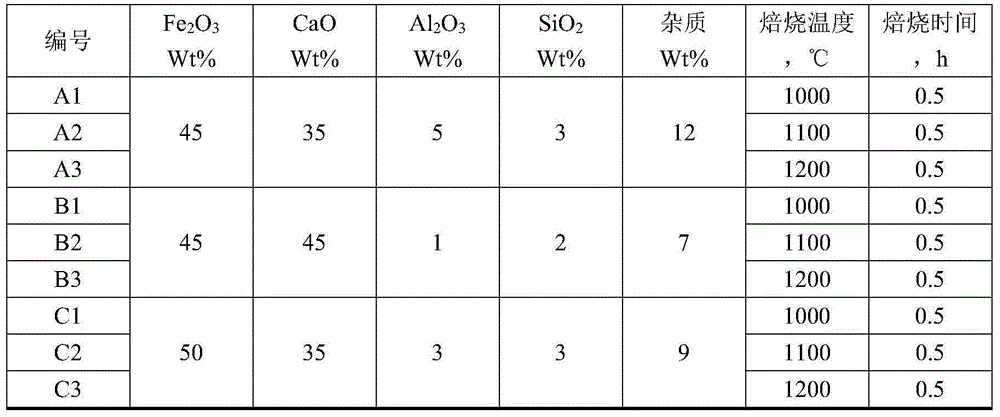

[0031] According to the above preparation method of vanadium extracting and dephosphorizing agent, 9 groups of calcium ferrite dephosphorizing agents were prepared. The main parameters of its composition and preparation are shown in Table 2. At the same time, three groups of vanadium-extracting agents with different components were prepared, as shown in Table 3. The obtained calcium ferrite dephosphorization agent and vanadium extraction agent were prepared into 11 groups of vanadium extraction and dephosphorization agents according to the ratio of 1:0.5.

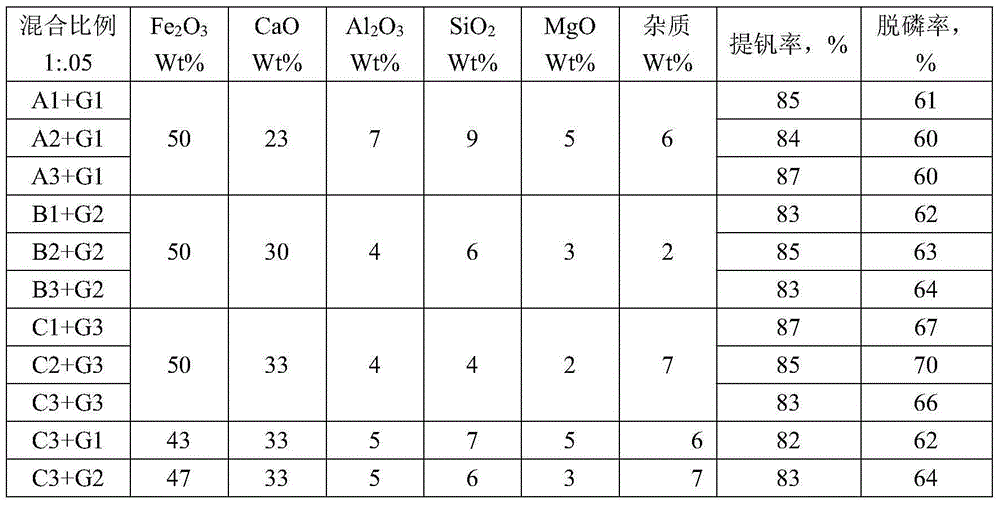

[0032]In an induction furnace equipped with 10kg of vanadium-containing molten iron (V0.3wt%, P0.08wt%), adding 40kg of vanadium-extracting and dephosphorizing agent per ton of molten iron, adding the above-prepared extractors of different compositions to the vanadium-containing molten iron. Vanadium dephosphorization agent. Table 4 shows the vanadium extraction and dephosphorization effect of vanadium extraction and deph...

example 2

[0040] According to the preparation method of the above-mentioned vanadium extracting and dephosphorizing agent, on the basis of Example 1, the roasting time of the calcium ferrite dephosphorizing agent was increased to 1 hour, and 9 groups of calcium ferrite dephosphorizing agents were prepared. The main parameters of its composition and preparation are shown in Table 5. The composition of vanadium extracting agent is shown in Table 3. The obtained calcium ferrite dephosphorizing agent and vanadium extracting agent were prepared according to the ratio of 1:1 to obtain 11 groups of vanadium extracting and dephosphorizing agent.

[0041] In an induction furnace equipped with 10kg of vanadium-containing molten iron (V0.28wt%, P0.09wt%), adding 50kg of vanadium-extracting and dephosphorizing agent per ton of molten iron, adding the above-prepared extractors of different compositions to the vanadium-containing molten iron. Vanadium dephosphorization agent. The composition of van...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com