Rope head provided with coating and preparation method of rope head

A technology of rope head and coating, applied in the field of coated rope head and its preparation, can solve problems such as difficult to realize, achieve the effects of reducing pollution, less harm to human body, and achieving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A coated rope end with a glossy effect and a hard feel. Including the uncoated white rope body and the yellow coated rope end, the total length is 1500mm, of which the length of the coated rope end is 30mm.

[0059] The preparation method of the coated rope end is as follows:

[0060] (1) singeing

[0061] Put the rope on the singeing machine to singe the whole rope.

[0062] (2) Paint mixing

[0063] Modulated by:

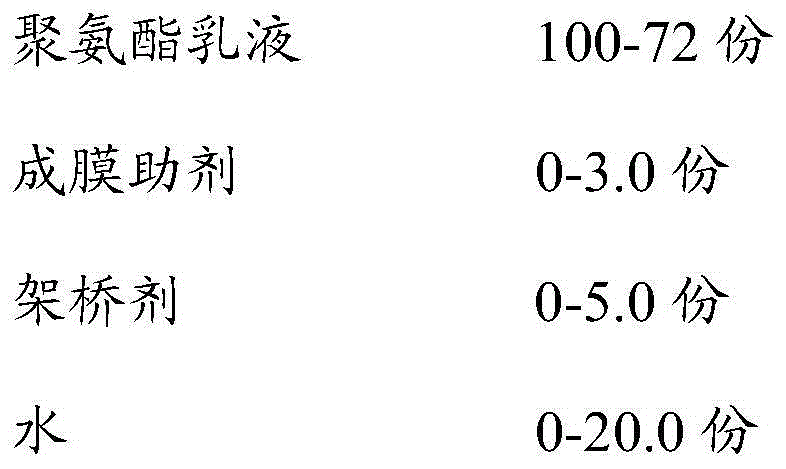

[0064] Each raw material is by weight ratio in the primer:

[0065] Polyurethane emulsion: bridging agent: water = 85:5.0:10.

[0066] Under stirring, first add the bridging agent into the water, and disperse evenly, then slowly add the mixture into the polyurethane emulsion, disperse evenly, and obtain a primer with a viscosity of 15-20S and a solid content of 32-35%.

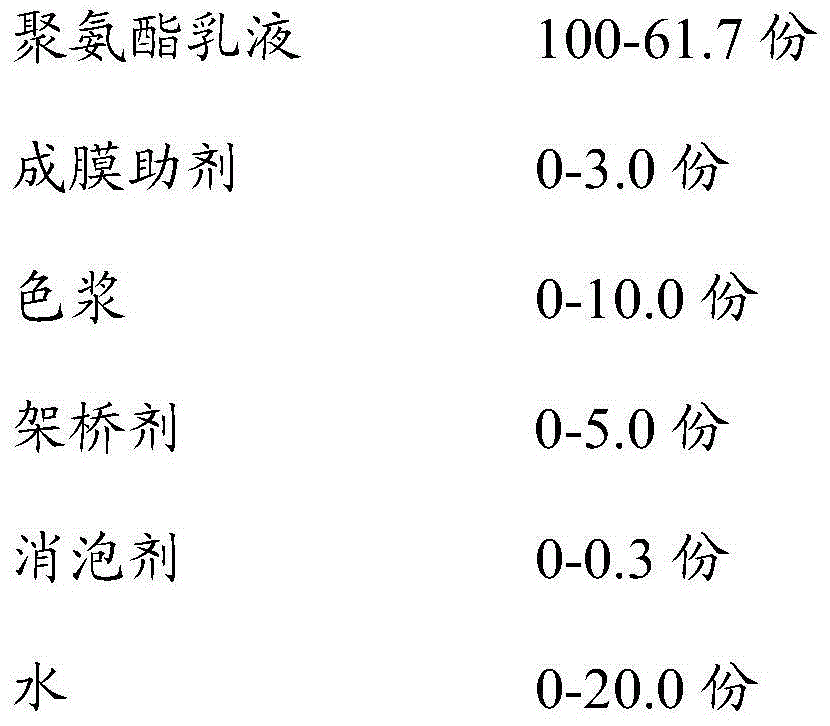

[0067] Each raw material is by weight ratio in the colored paint:

[0068] Yellow paint, polyurethane emulsion: yellow color paste: bridging agent: defoamer: water = 77.7:7.0:5.0:0.3...

Embodiment 2

[0091] A coated rope end with a glossy effect and a stiffer feel. Including the uncoated white rope body and the red and blue coated rope heads from top to bottom, the total length is 1500mm, of which the length of the coated rope head is 30mm, the length of the red coating is 10mm, and the length of the blue coating is 10mm. The coating length is 20 mm.

[0092] The preparation method of the coated rope end is as follows:

[0093] (1) singeing

[0094] Put the rope on the singeing machine to singe the part of the rope to be coated.

[0095] (2) Paint mixing

[0096] Modulated by:

[0097] Each raw material is by weight ratio in the primer:

[0098] Polyurethane emulsion: water = 90:10.

[0099] Under stirring, slowly add water into the polyurethane emulsion, disperse evenly, and obtain a primer with a viscosity of 15-25S and a solid content of 30-35%.

[0100] Each raw material is by weight ratio in the colored paint:

[0101] Red color paint, polyurethane emulsion: r...

Embodiment 3

[0126] A coated rope end with a matte, loose finish and a medium-soft coating. Including the uncoated white rope body and the red and blue coated rope heads from top to bottom, the total length is 1500mm, of which the length of the coated rope head is 30mm, the length of the red coating is 10mm, and the length of the blue coating is 10mm. The length of the coating is 20mm, and the length of the loose head is 10mm.

[0127] The preparation method is as follows:

[0128] (1) singeing

[0129] Put the rope on the singeing machine to singe the whole rope.

[0130] (2) Paint mixing

[0131] Modulated by:

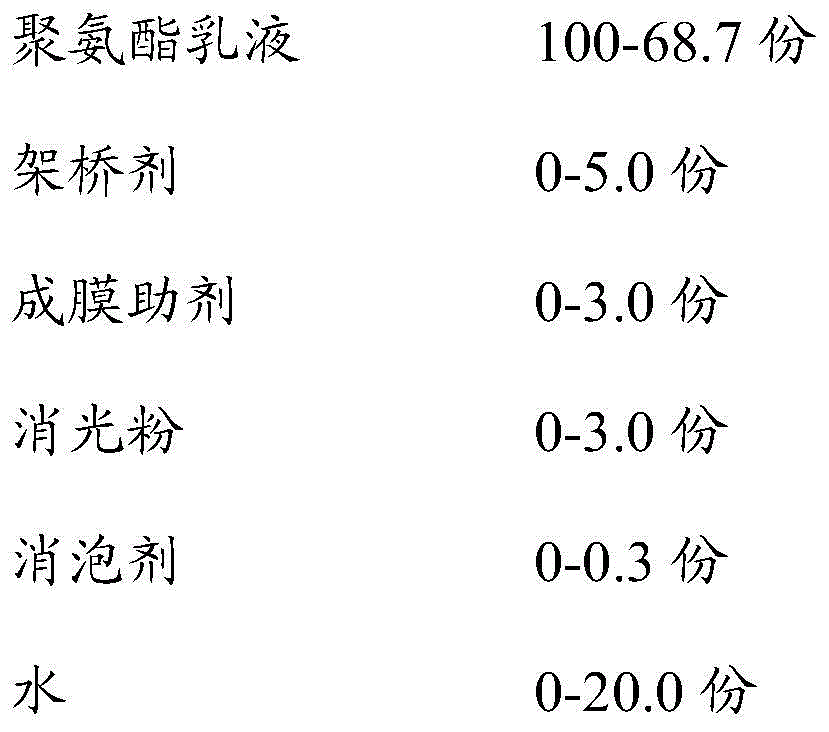

[0132] Each raw material is by weight ratio in the primer:

[0133] Polyurethane emulsion: coalescent: bridging agent: water = 86:2.0:2.0:10.

[0134] Under stirring, first add the film-forming aid (specifically isopropanol: propylene glycol butyl ether: alcohol ester twelve weight parts ratio is 1:2:3) and bridging agent into the water, after the dispersion is uniform, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com