Stone texture imitating permeable concrete prefabricated brick and preparation method thereof

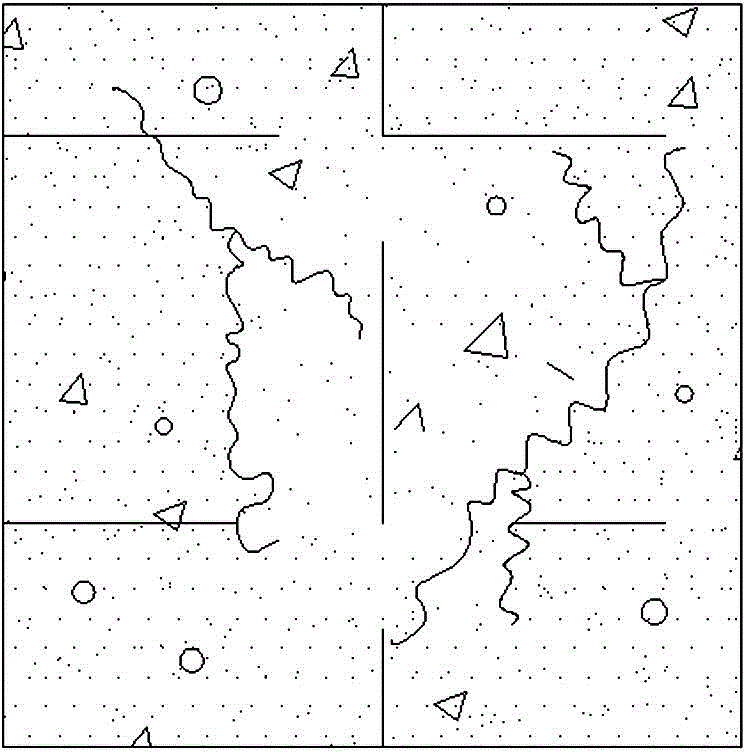

A technology of permeable concrete and imitation stone, which is applied to the pavement paved with prefabricated blocks, manufacturing tools, ceramic molding machines, etc., can solve the problems of lack of texture pavement of cast-in-place imitation stone and poor decorative effect of permeable bricks, etc., to achieve Alleviate the heat island effect, diversify the decorative effect, and have natural and diverse textures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

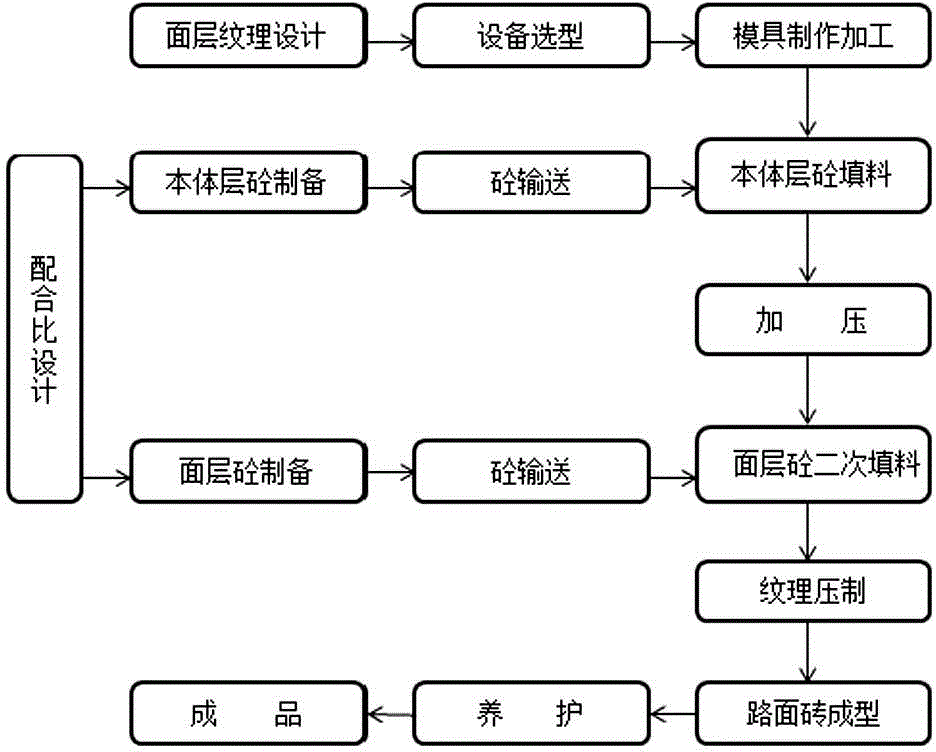

Method used

Image

Examples

Embodiment 1

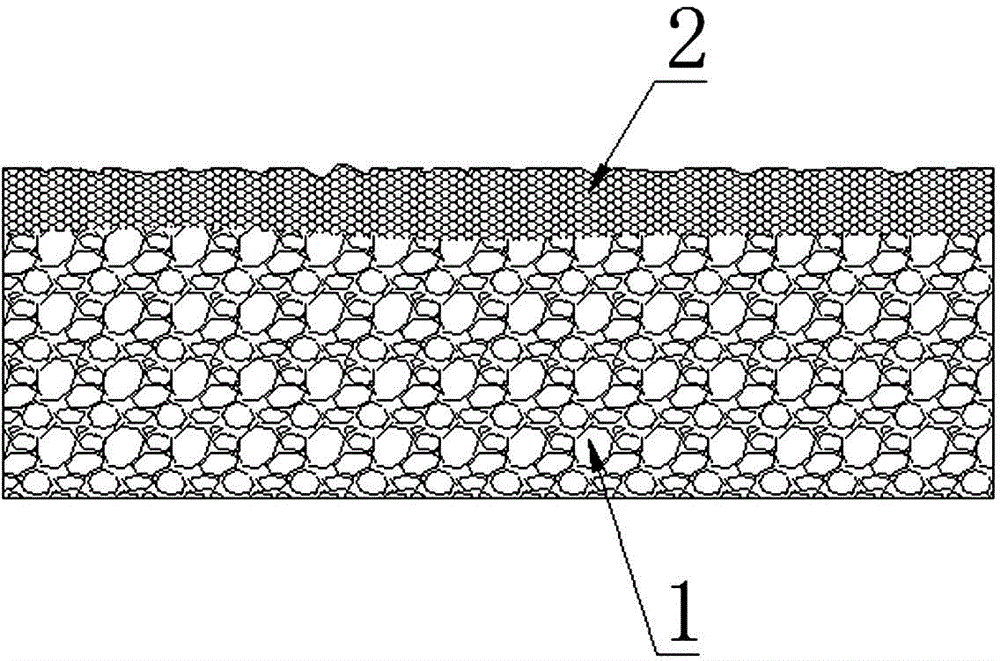

[0037] The weight ratio of the raw materials used in the permeable concrete prefabricated brick permeable body layer 1 with imitation stone texture and the mortar per cubic meter is: (a) the aggregate is crushed stone, and the dosage is 1400kg / m 3 , Gravel particle size is 5mm ~ 10mm. (b) Cement (P.O42.5R): 350kg / m 3 . (c) Water reducer: 3.5kg / m 3 . (d) Fly ash: 35kg / m 3 .

[0038] Stone-like texture permeable concrete prefabricated brick imitation stone-textured permeable surface layer 2 The weight ratio of raw materials and mortar per cubic meter is: (a) The fine aggregate is quartz sand, and the addition amount is 1500kg / m 3 . The gradation of quartz sand is: 20 mesh accounts for 70%; 48 mesh accounts for 30%. (b) Cement: 360kg / m 3 . (c) Pigment: 8kg / m 3 . (d) Water reducing agent: 4kg / m 3 . (e) Silica fume: 45kg / m 3 . (f) Fly ash: 40kg / m 3 .

[0039] Performance indicators of prefabricated bricks: strength of permeable body layer: 32.5MPa; strength of...

Embodiment 2

[0041] The weight ratio of the raw materials used in the permeable concrete prefabricated brick permeable body layer 1 with imitation stone texture and the mortar per cubic meter is: (a) the aggregate is crushed stone, and the dosage is 1530kg / m 3 , Gravel particle size is 5mm ~ 10mm. (b) Cement: 340kg / m 3 . (c) Water reducer: 3.4kg / m 3 . (d) Fly ash: 34kg / m 3 .

[0042] The stone-like texture permeable concrete prefabricated brick imitation stone texture permeable surface layer 2 uses the raw materials and the weight ratio per cubic meter of mortar: (a) The fine aggregate is quartz sand, and the addition amount is 1722kg / m 3 . The gradation of quartz sand is: 20 mesh accounts for 80%; 48 mesh accounts for 20%. (b) Cement: 340kg / m 3 . (c) Pigment: 3kg / m 3 . (d) Water reducer: 3.5kg / m 3 . (e) Silica fume: 40kg / m 3 . (f) Fly ash: 30kg / m 3 .

[0043] Performance indicators of prefabricated bricks: strength of permeable body layer: 25.8MPa; strength of permeabl...

Embodiment 3

[0045] The weight ratio of the raw materials used in the permeable concrete prefabricated brick permeable body layer 1 with imitation stone texture and the mortar per cubic meter is: (a) the aggregate is crushed stone, and the dosage is 1550kg / m 3 , Gravel particle size is 5mm ~ 10mm. (b) Cement: 310kg / m 3 . (c) Water reducer: 3.1kg / m 3 . (d) Fly ash: 31kg / m 3 .

[0046] Stone texture imitation permeable concrete prefabricated bricks imitation stone texture permeable surface layer 2 The weight ratio of raw materials and mortar per cubic meter is: (a) The fine aggregate is quartz sand, and the addition amount is 1800kg / m 3 . The gradation of quartz sand is: 20 mesh accounts for 90%; 48 mesh accounts for 10%. (b) Cement: 330kg / m 3 . (c) Pigment: 4kg / m 3 . (d) Water reducer: 3.3kg / m 3 . (e) Silica fume: 40kg / m 3 . (f) Fly ash: 30kg / m 3 .

[0047] Performance indicators of prefabricated bricks: strength of permeable body layer: 21.5MPa; strength of permeable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com