Diesel generator cogeneration device based on ORC (organic Rankine cycle) system

A technology for diesel generators and thermal power generation, which is applied in steam engine devices, machines/engines, mechanical equipment, etc. It can solve the problems of limited application and popularization, complex cost and control, cracking failure of ORC refrigerant, etc., and achieves compact structure and improved fuel efficiency. Economical and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

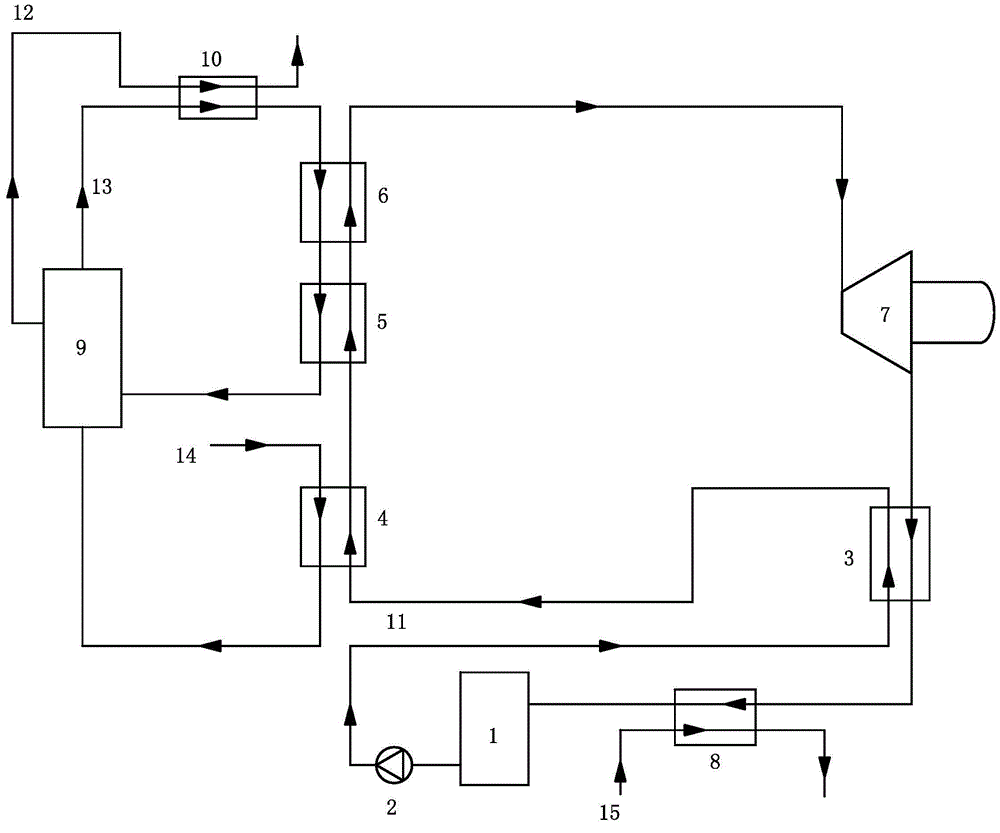

[0024] Referring to the accompanying drawings, an ORC system-based diesel generator waste heat power generation device of the present invention includes five subsystems such as an ORC refrigerant circulation system, an engine jacket water circulation system, an engine exhaust system, a pressurized air system and an external cooling water system. The specific workflow and energy transfer process of the five subsystems are introduced below:

[0025] 1) ORC refrigerant circulation system

[0026] The refrigerant working medium 2 in the liquid storage tank 1 is first pressurized by the refrigerant pump 2, and then enters the air cooler 4 to absorb the heat of the pressurized air flowing through the air cooler at a temperature of 150-200°C; then it passes through the preheater in turn 5. The evaporator 6 absorbs the heat of the jacket water, evaporates and changes its phase, and becomes high-temperature and high-pressure steam; the high-temperature and high-pressure refrigerant flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com