Wind power tower

A technology for wind power towers and cylinders, which is applied in wind power generation, wind turbine components, wind engines, etc., can solve problems such as single function, influence on wind energy utilization, and loosening of joints to ensure normal operation, The effect of prolonging the service life and not being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

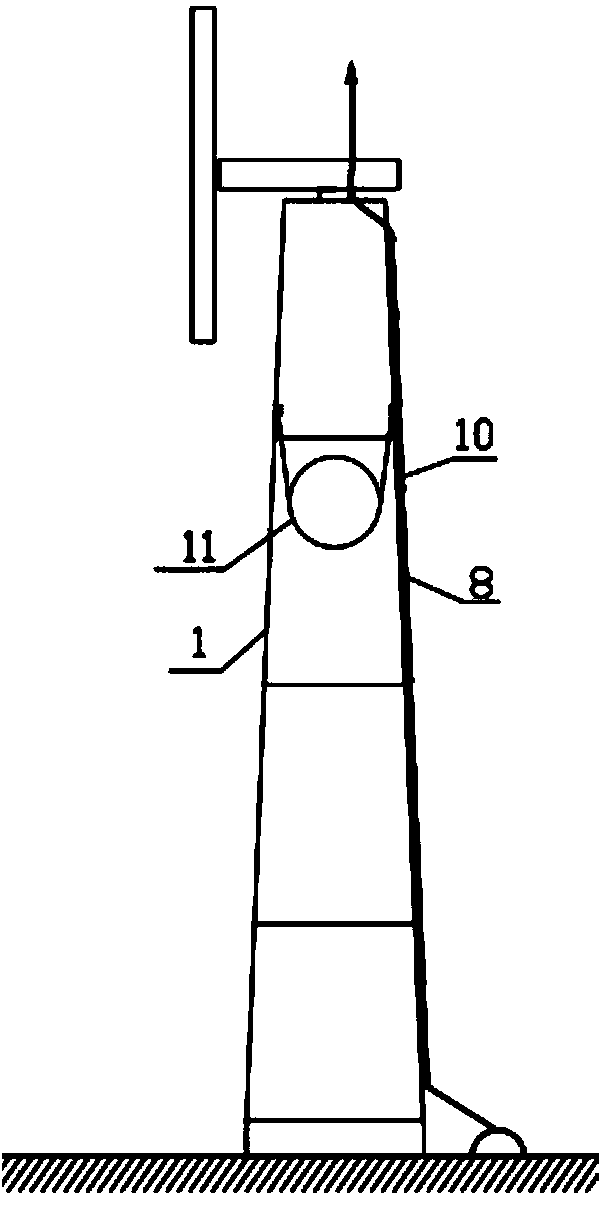

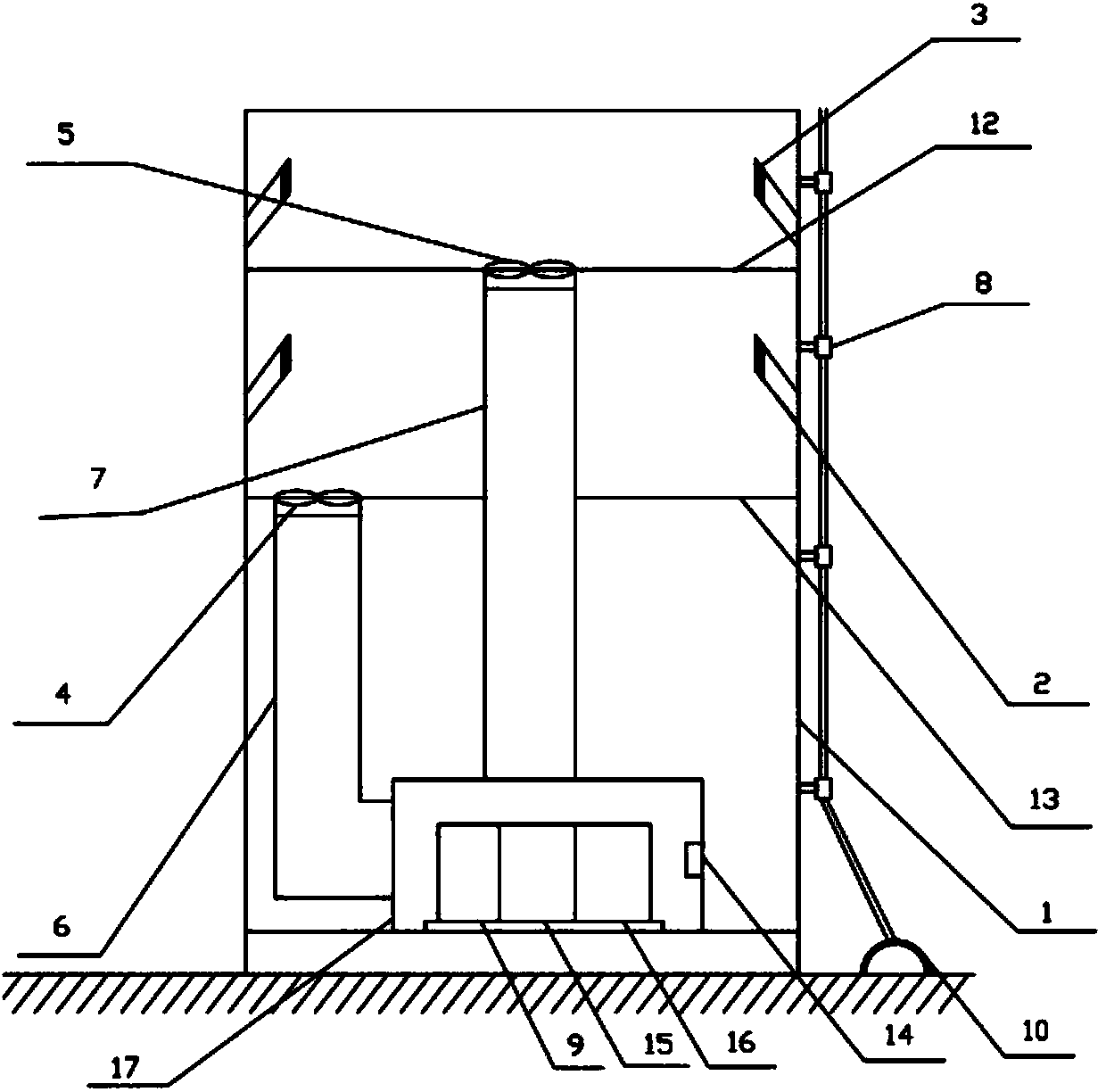

[0011] In the figure, 1. Cylinder body, 2. Ventilation pipe, 3. Filter screen, 4. Fan A, 5. Fan B, 6. Air supply pipe, 7. Air outlet pipe, 8. Insulator, 9. Frequency converter, 10 , lightning protection device, 11, wind damper, 12, upper partition plate, 13, lower partition plate, 14, temperature control device, 15, reactor, 16, transformer, 17, studio.

[0012] Such as figure 1 , figure 2 As shown, the lightning protection device 10 is arranged outside the cylinder body 1, and is fixedly connected with the cylinder body 1 with an insulator 8. The ventilation pipe 2 is fixedly connected on the inner wall of the cylinder body 1. The ventilation pipe 2 is divided into upper and lower layers, and each layer is composed of several Two ventilation pipes 2 form a circle, and the interval between the ventilation pipe 2 and the ventilation pipe 2 is the same. , the lower partit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com