Micro-pressure sensor and manufacturing and detecting method thereof

A technology of micro pressure sensor and pressure sensor, which is applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc., can solve the problems of difficult processing, difficult film thickness, poor linearity, etc., and achieve the convenience of sensitive pressure detection, The effect of high quality factor and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A typical implementation of a micro pressure sensor of the present invention and its preparation and detection methods will be described in detail below in conjunction with the accompanying drawings:

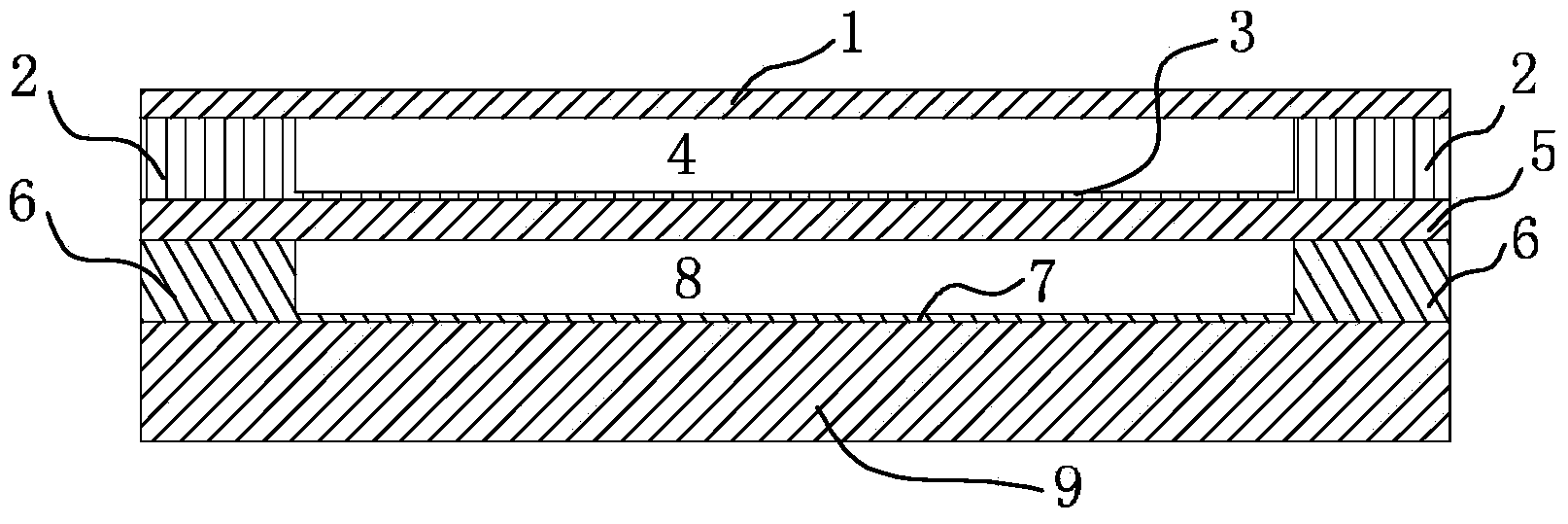

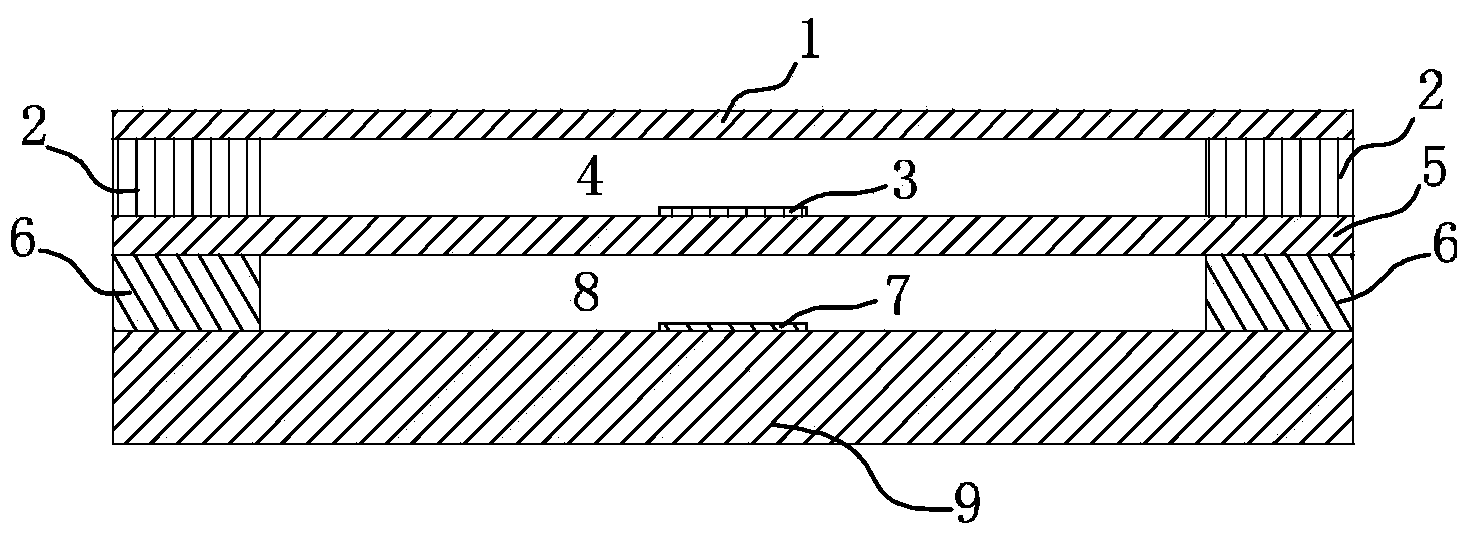

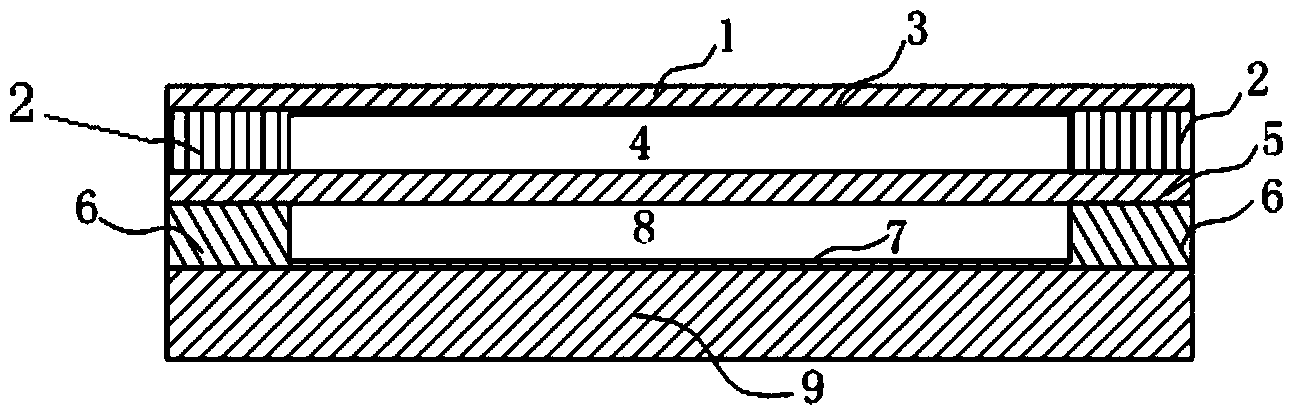

[0038] See attached figure 1 , the detailed structural features of the present invention are described:

[0039] A micro pressure sensor according to the present invention, the main body structure of the sensor includes an upper thin plate 1, a middle thin plate 5 and a base 9 from top to bottom; wherein, an upper pillar 2, an upper insulating layer 3 and The upper cavity 4, the upper pillar 2 surrounds the upper cavity 4, the upper side and the lower side of the upper pillar 2 are the upper thin plate 1 and the middle thin plate 5 respectively, the upper insulating layer 3 is located on the upper surface of the middle thin plate 5, the upper thin plate 1, the upper pillar 2 and the middle thin plate 5 together form an upper cavity 4; wherein, a lower pillar 6, a lower i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com