An electromagnetic bandgap structure, combination of electromagnetic bandgap structures and mobile terminal mimo antenna

An electromagnetic bandgap structure, mobile terminal technology, applied in the direction of radiation element structure, antenna support/installation device, etc., can solve the problems of lack of flexibility, difficult to adapt, etc., to increase radiation efficiency, easy to implement, and improve the gain. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

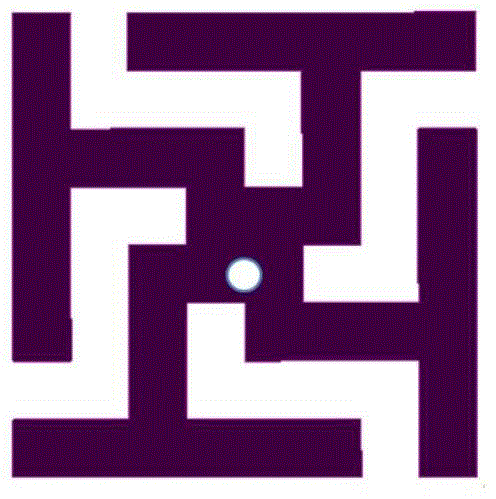

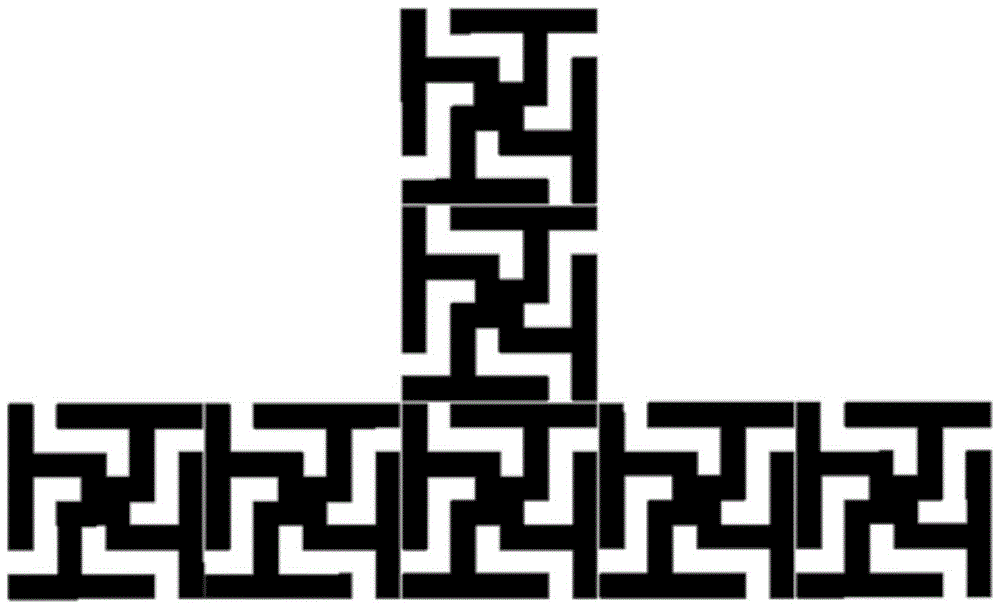

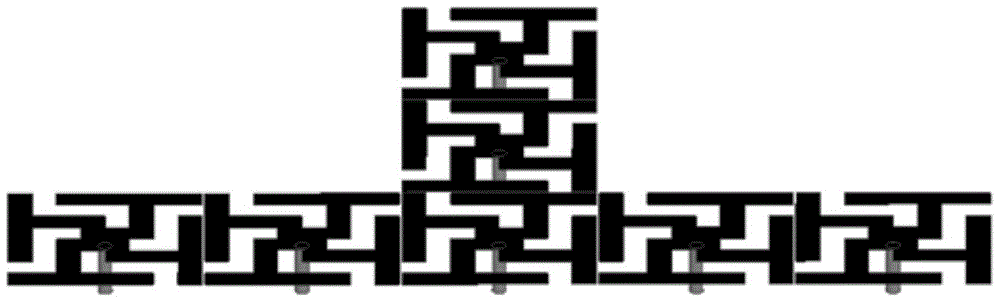

[0027] In order to improve the isolation of the antenna, the present invention provides an electromagnetic bandgap structure (or called an electromagnetic bandgap unit), which includes a metal patch, and the metal patch has a metal via hole. When using the electromagnetic bandgap structure, the metal vias can penetrate the dielectric plate, and the metal patches are connected to the metal bottom plate on the other side of the medium through the metal vias, thus forming a resonant electromagnetic bandgap structure. The axis of the metal via may not coincide with the center of the metal patch, so there is a certain offset. Preferably, the axis of the metal via hole is located in the middle of the metal patch.

[0028] Electromagnetic bandgap structure such as figure 1 As shown, in practice, the slits are etched for a square metal patch of 8mm×8mm, and the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com