Encircling type high-density injection waveguide laser device and laser generating method

A waveguide laser, high-density technology, applied in the field of lasers, can solve the problems of output power reduction, gain fiber length limitation, heat increase, etc., and achieve the effect of increasing power, increasing reflection ability, and high electrical-optical conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

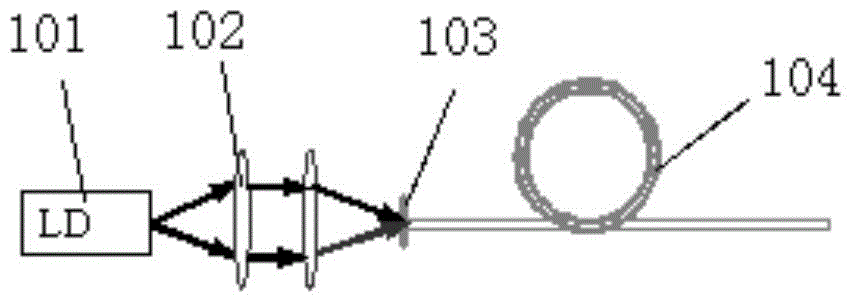

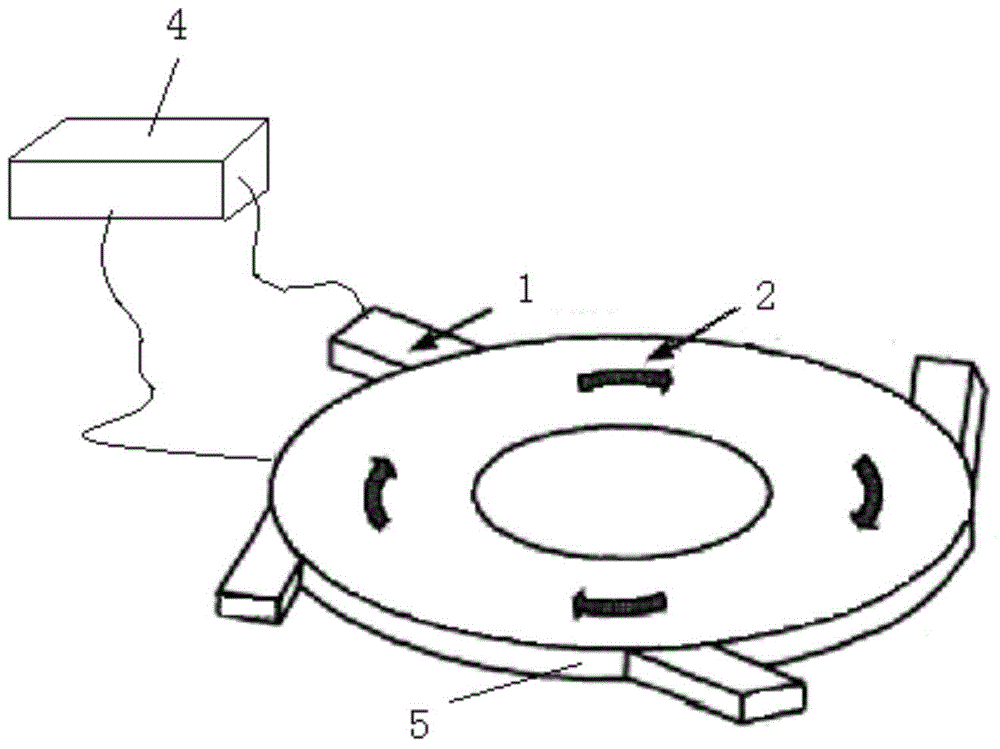

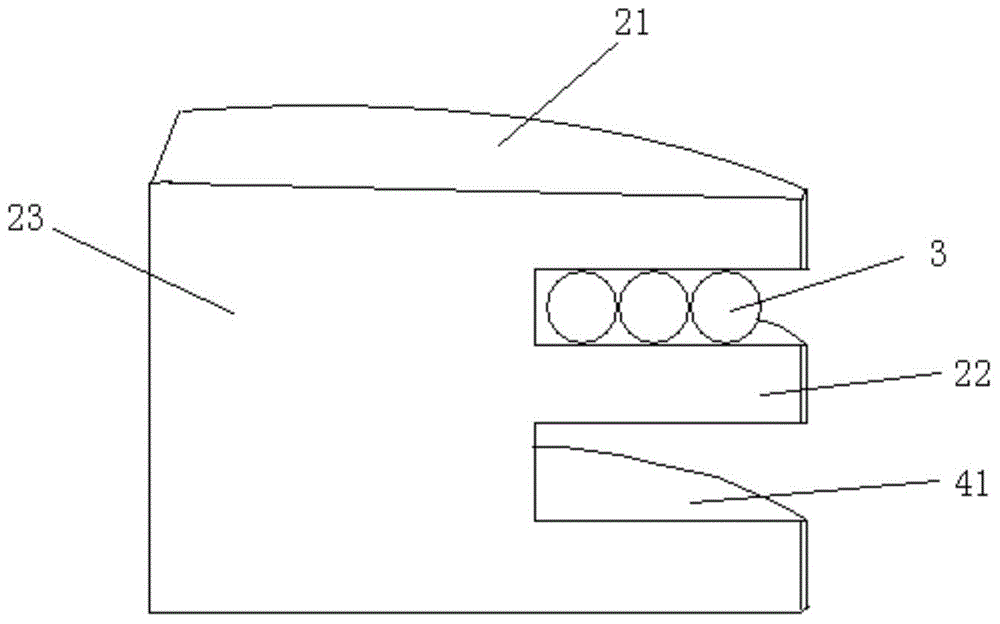

[0032] The structure of this laser designed by the present invention is: mainly by LD pumping array 1, metal waveguide 2, gain fiber 3 and cooling system 4 several parts, as figure 2 shown.

[0033] The LD pump itself belongs to the existing technology products, with high power, high stability, high beam quality, small size, light weight, firm structure, long life and many other advantages. It is used in various fields such as industry, communication, military and medical treatment. The so-called pump array is to combine multiple pumps into the laser in a certain way to achieve high-power laser output. The LD pumping array 1 is mainly composed of LD, power drive, temperature control and other parts. Considering the need to achieve high-power laser output, the pump source uses a high-power semiconductor laser diode array. The arrangement of the pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com