Wind power generation system based on full wave chop-control rectifying circuits

A technology of wind power generation system and rectifier circuit, which is applied in wind power generation, irreversible AC power input conversion into DC power output, single-grid parallel feeding arrangement, etc. The effect of low maintenance cost, simple control and protection, and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

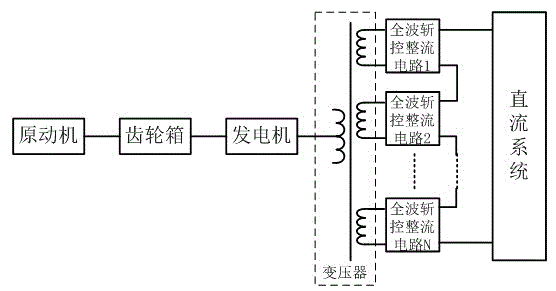

[0049] A wind power generation system based on a full-wave chopper-controlled rectifier circuit is characterized in that it is composed of a prime mover, a gear box, a generator, a transformer, N full-wave chopper-controlled rectifier circuits and a DC system.

[0050] Among them, the prime mover converts the wind force into the mechanical energy of the wind blade rotation, and after being accelerated by the gearbox, it drives the rotor of the generator to rotate, and the generator converts the mechanical energy into electrical energy.

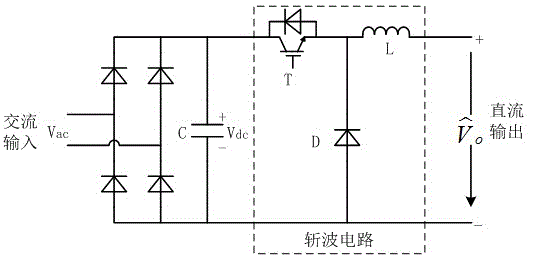

[0051] The output of the generator is connected to the primary winding of the transformer, and the secondary winding of the transformer has N mutually isolated coils, and each coil is connected to the AC input of the full-wave chopper-controlled rectifier circuit.

[0052] The DC outputs of the N full-wave chopper-controlled rectifier circuits are connected in series, and then connected to the DC system.

[0053] The DC system is used for the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com