Terminal-equipped electric wire and manufacturing method for same

A manufacturing method and wire technology, which can be applied to circuits, conductive connections, electrical components, etc., can solve problems such as poor contact, insufficient adhesion between insulating coating and waterproof resin, and corrosion of the connection between core wires and metal terminals. , to achieve the effect of improving water resistance and shortening preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

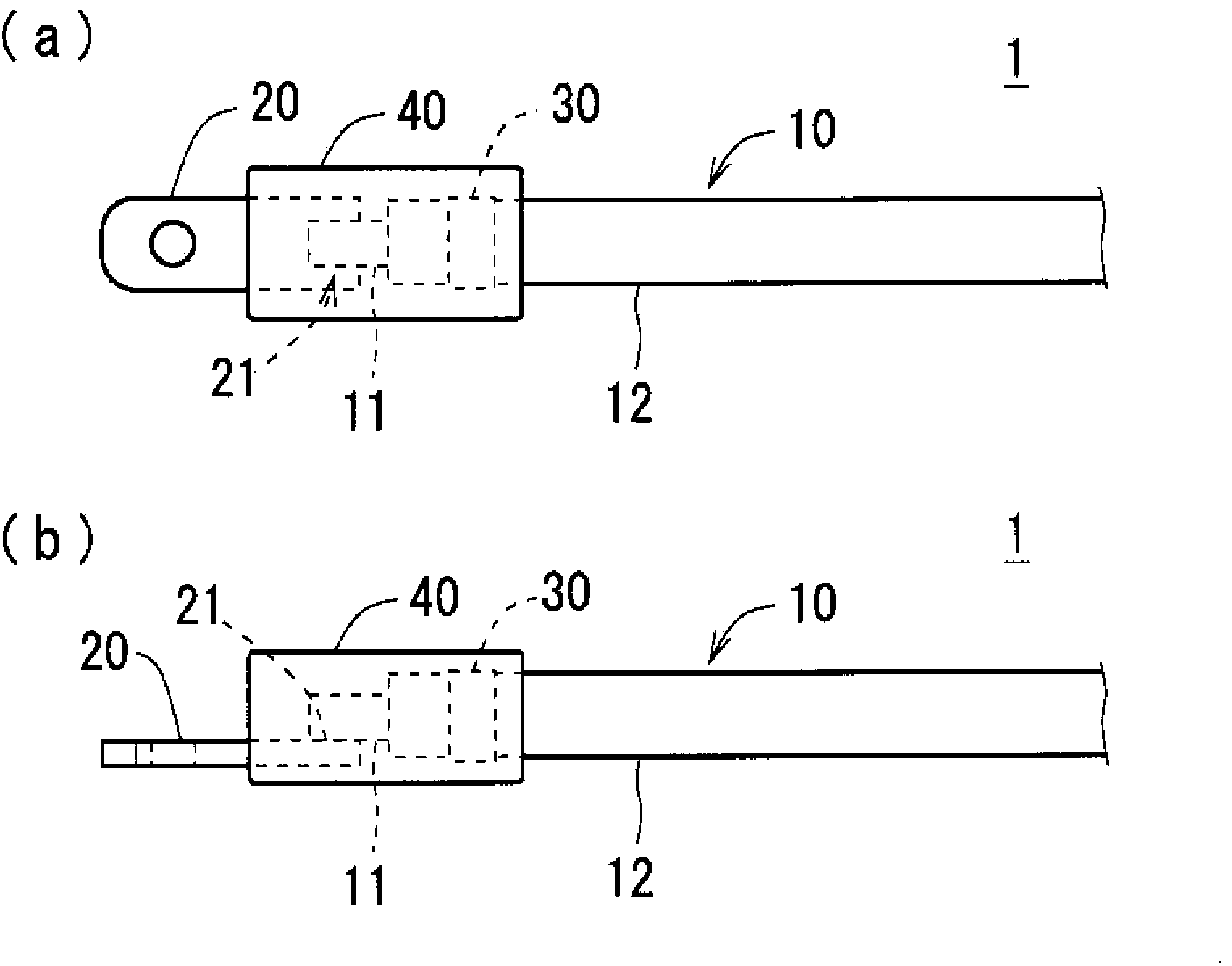

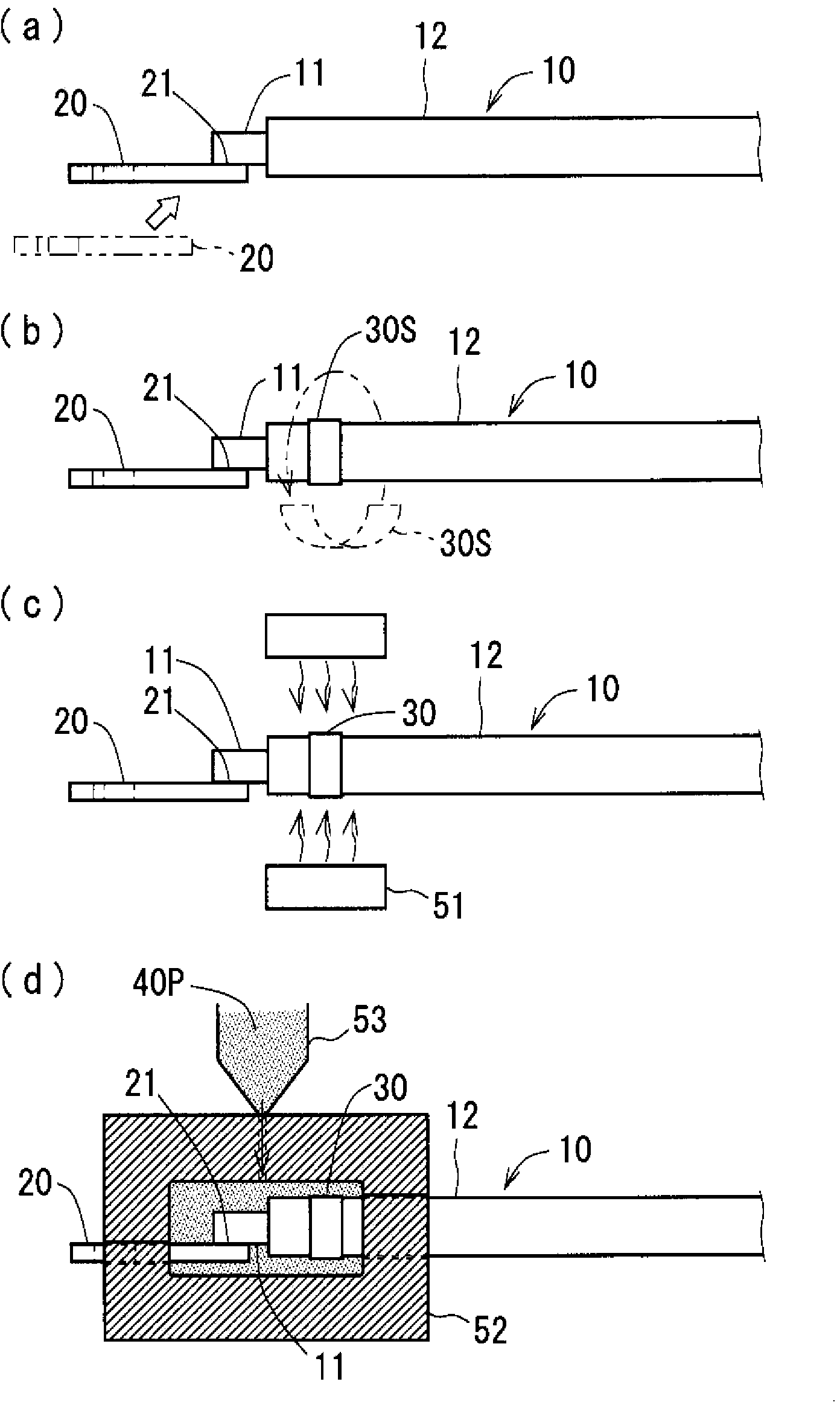

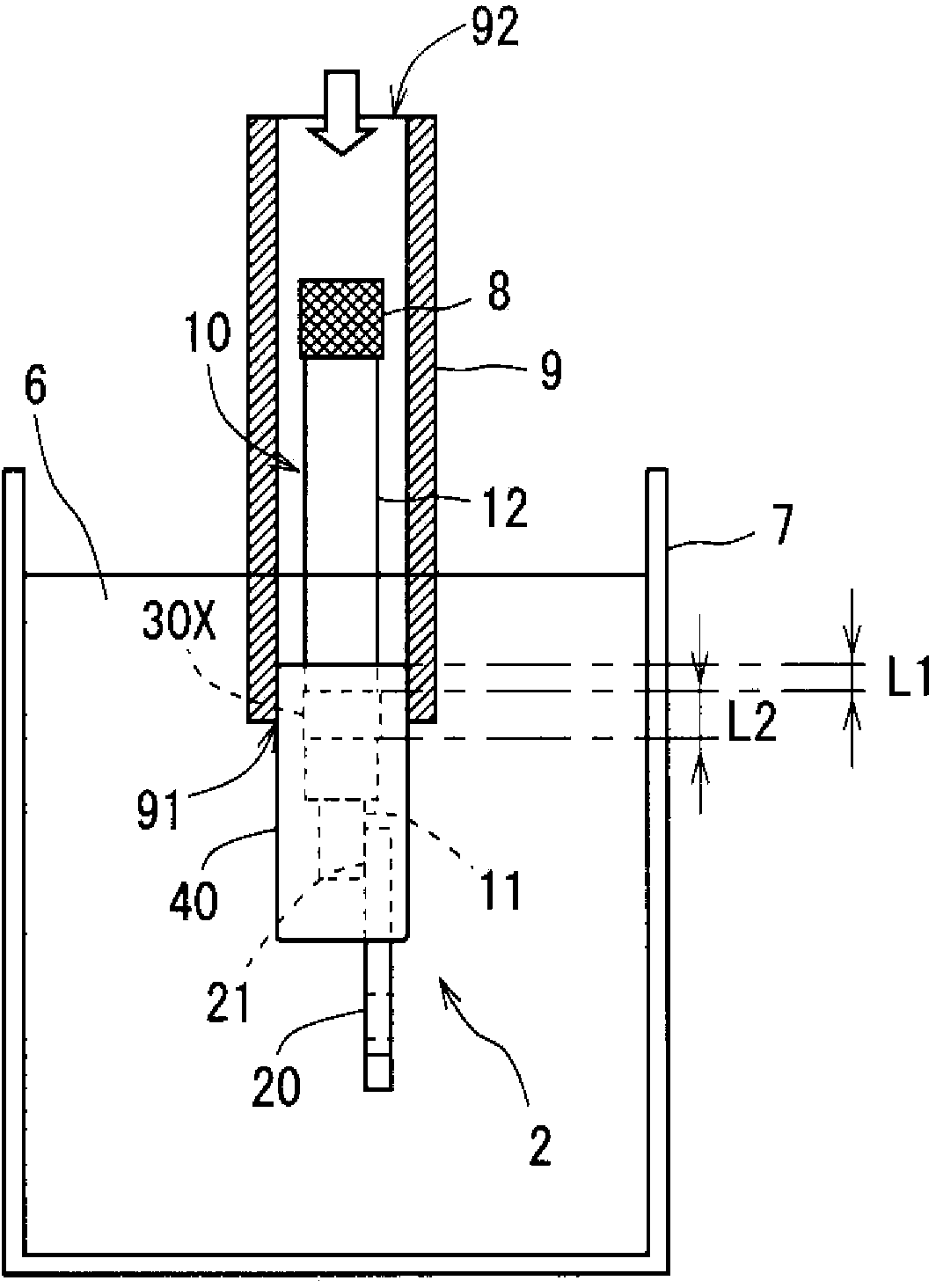

[0035] First, refer to figure 1 The configuration of the terminal-provided electric wire 1 according to the embodiment of the present invention will be described. Such as figure 1 As shown, the terminal-equipped electric wire 1 includes an insulated electric wire 10 , a metal terminal 20 , an adhesive layer 30 , and a waterproof resin portion 40 .

[0036] The insulated wire 10 has a conductive core wire 11 and an insulating coating layer 12 of polyolefin resin covering the periphery of the core wire 11 . In the insulated electric wire 10 , the end of the core wire 11 is formed by extending from the end of the insulating coating 12 .

[0037] The core wire 11 is made of metal materials such as copper, copper alloy, or aluminum alloy, for example. On the other hand, the insulating coating layer 12 is made of, for example, a polyolefin resin such as cross-linked polyethylene or cross-linked polypropylene.

[0038] The metal terminal 20 is a terminal electrically connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com