Integrated semi-dry purifying method for sintering flue gas

A sintering flue gas, semi-dry technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc. Flue gas purification device and other problems, to achieve the effect of easy control and adjustment, small footprint, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

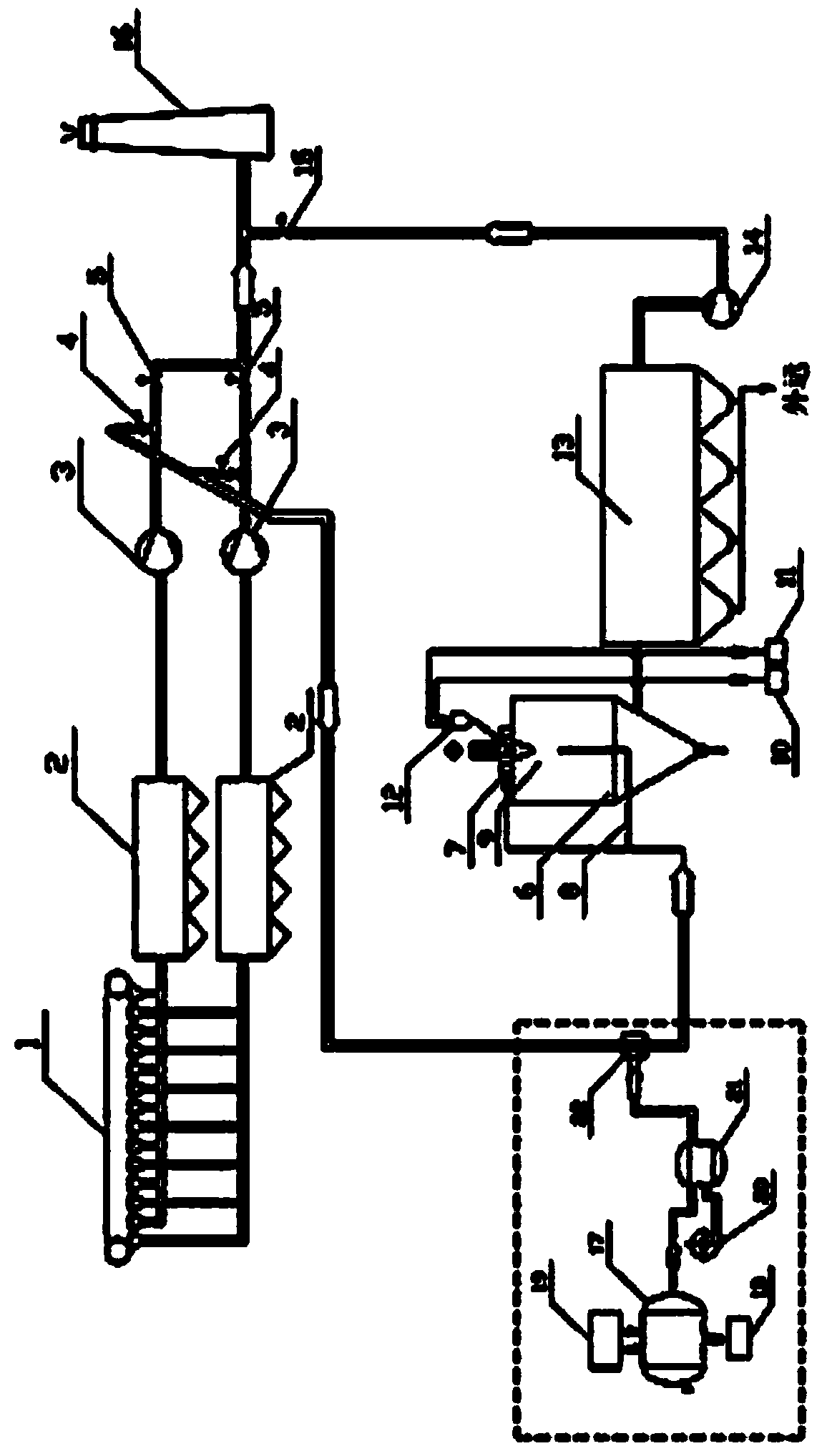

[0058] [Example 1] Applying a semi-dry sintering flue gas integrated purification method of the present invention to the B series 328m 2 Purification of sintering machine flue gas

[0059] In this embodiment, the B series 328m 2 The original rotary spray drying desulfurization system of the sintering machine is modified, and the oxidant generation and distribution device is connected to the flue gas pipeline in front of the rotary spray drying desulfurization tower 6. The modified device includes a rotary spray drying desulfurization tower 6 and a bag-type dust removal purification and discharge device connected through a flue gas delivery pipeline. The rotary spray drying desulfurization tower 6 is also connected to a lime slurry preparation and delivery device 10 and a process cooling water supply device 11. The flue gas input pipe in front of the rotary spray drying desulfurization tower 6 is additionally connected to the oxidant generating and distributing device.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com