Sludge dewatering treatment method

A technology of sludge dewatering and treatment method, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve the problems of high water content and decrease, and achieve the effect of increasing the dehydration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

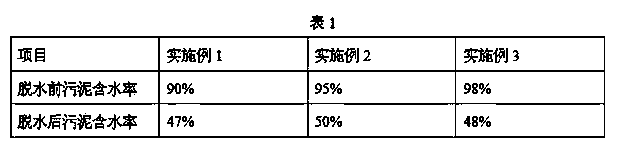

Embodiment 1

[0023] Embodiment 1: Take the sludge at the bottom of the sedimentation tank in the seawater circulating water fish farming system, add water to reconcile the sludge water with a water content of 90%. Measured by sludge water, add 1500 mg / L of cationic surfactant, cetyltrimethylammonium bromide, and stir for 5 minutes. Then add 5000 mg / L ferric chloride and stir for 5 minutes; then add 250 mg / L polyacrylamide and stir for 10 minutes. Put the sludge water into the agitator, which is a cylindrical utensil made of plexiglass, and the agitator can be connected to a regulated DC power supply for electrochemical treatment. Stirrer with Ir / RuO 2 The electrode plate is the anode, Ti / RuO 2 The mesh pole plate is the cathode, and the pole plate distance between the cathode and the anode is 4cm. During the electrochemical treatment, the voltage was 28V, and the electrochemical reaction took 20 minutes. Put the treated sludge water into a centrifugal dehydrator to concentrate, remove ...

Embodiment 2

[0024] Embodiment 2: Take the sludge at the bottom of the sedimentation tank in the seawater circulating water fish farming system, add water to reconcile into sludge water with a water content of 95%. Measured by sludge water, add cationic surfactant, 2000 mg / L of dodecyl dimethyl benzyl ammonium chloride, and stir for 8 minutes. Then add ferric chloride 6500 mg / L and stir for 8 minutes; then add polyacrylamide 325 mg / L and stir for 7 minutes. Put the sludge water into the agitator, which is a cylindrical utensil made of plexiglass, and the agitator can be connected to a regulated DC power supply for electrochemical treatment. Stirrer with Ir / RuO 2 The electrode plate is the anode, Ti / RuO 2 The mesh pole plate is the cathode, and the pole plate distance between the cathode and the anode is 4cm. During the electrochemical treatment, the voltage was 29V, and the electrochemical reaction took 25 minutes. Put the treated sludge water into a centrifugal dehydrator to concentra...

Embodiment 3

[0025] Embodiment 3: take the sludge at the bottom of the sedimentation tank in the seawater circulating water fish farming system, add water to reconcile into sludge water with a water content of 98%. Measured by sludge water, add 2500 mg / L of cationic surfactant, cetyltrimethylammonium bromide, and stir for 10 minutes. Then add 8000 mg / L ferric chloride and stir for 10 minutes; then add 400 mg / L polyacrylamide and stir for 5 minutes. Put the sludge water into the agitator, which is a cylindrical utensil made of plexiglass, and the agitator can be connected to a regulated DC power supply for electrochemical treatment. Stirrer with Ir / RuO 2 The electrode plate is the anode, Ti / RuO 2 The mesh pole plate is the cathode, and the pole plate distance between the cathode and the anode is 4cm. During the electrochemical treatment, the voltage was 30V, and the electrochemical reaction was performed for 30 minutes. Put the treated sludge water into a centrifugal dehydrator to conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com