Modified nitrile-butadiene rubber sealing gasket material and preparation method thereof

A technology of nitrile rubber and sealing gasket is applied in the field of modified nitrile rubber sealing gasket material and its preparation, which can solve the problems of unsatisfactory sealing effect, poor wear resistance, low strength, etc., and achieves good pressure resistance and convenient process. , the effect of simple ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

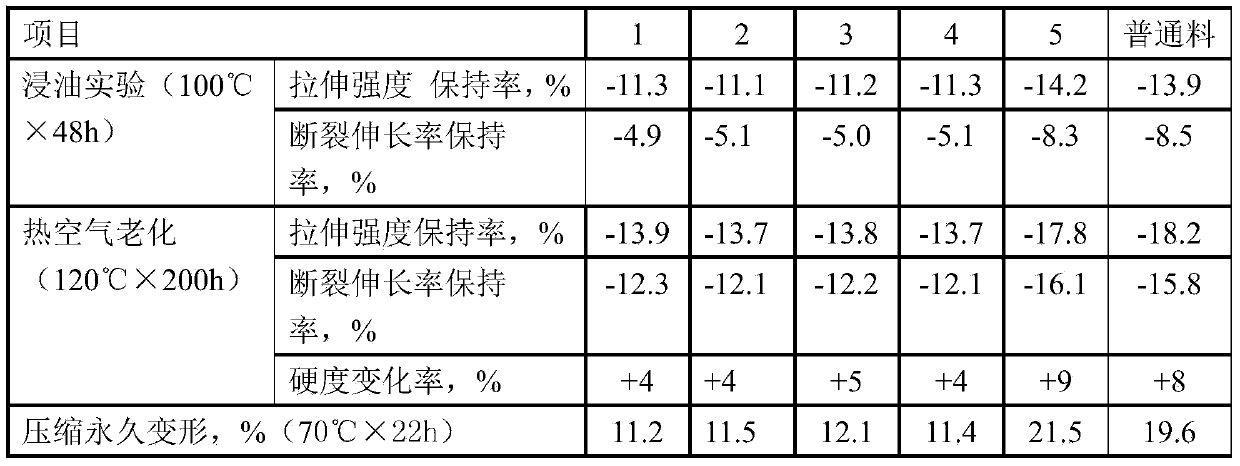

Examples

Embodiment 1

[0014] Add 100 parts of nitrile rubber and 10 parts of calcium terephthalate (length-to-diameter ratio: 11:1, particle size: 10um) into the internal mixer, heat to 80°C, knead for 3 minutes, then raise the temperature to 135°C, add 5 parts of anti-aging agent 4010, 3 parts of Si69, 5 parts of plasticizer DOP, 2.5 parts of accelerator M, 2 parts of sulfur, knead for 10 minutes, then add 30 parts of carbon black N330, 6 parts of stearic acid and continue kneading for 10 minutes, that is No. 1 rubber compound was obtained.

Embodiment 2

[0016] Add 100 parts of nitrile rubber and 20 parts of magnesium terephthalate (length-to-diameter ratio: 15:1, particle size: 13um) into the internal mixer, heat to 100°C, knead for 5 minutes, then raise the temperature to 135°C, add 1 part of anti-aging agent RD, 5 parts of Si69, 20 parts of plasticizer DTOP, 1 part of accelerator DM, 1 part of sulfur, knead for 5 minutes, then add 15 parts of carbon black N330, 3 parts of stearic acid and continue kneading for 5 minutes to obtain No. 2 Gum.

Embodiment 3

[0018] Add 100 parts of nitrile rubber and 15 parts of zinc terephthalate (with aspect ratio of 7:1 and particle size of 10um) into the internal mixer, heat to 90°C, knead for 4 minutes, then raise the temperature to 135°C, add 3 parts of anti-aging agent MB, 4 parts of Si694, 10 parts of plasticizer DBP, 1.5 parts of accelerator DTDM, 1.5 parts of sulfur, knead for 8 minutes, add 20 parts of carbon black N330, 5 parts of stearic acid and continue kneading for 8 minutes to obtain 3 Rubber material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com