Feeding device and cooling system for slag cooler of fluidized bed garbage incinerator

A technology of waste incinerator and feeding device, which is applied to incinerators, combustion methods, combustion types, etc., can solve the problems of air leakage at the dredging port, equipment wear, and unstable circulation, so as to avoid dangerous operations, high work efficiency, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

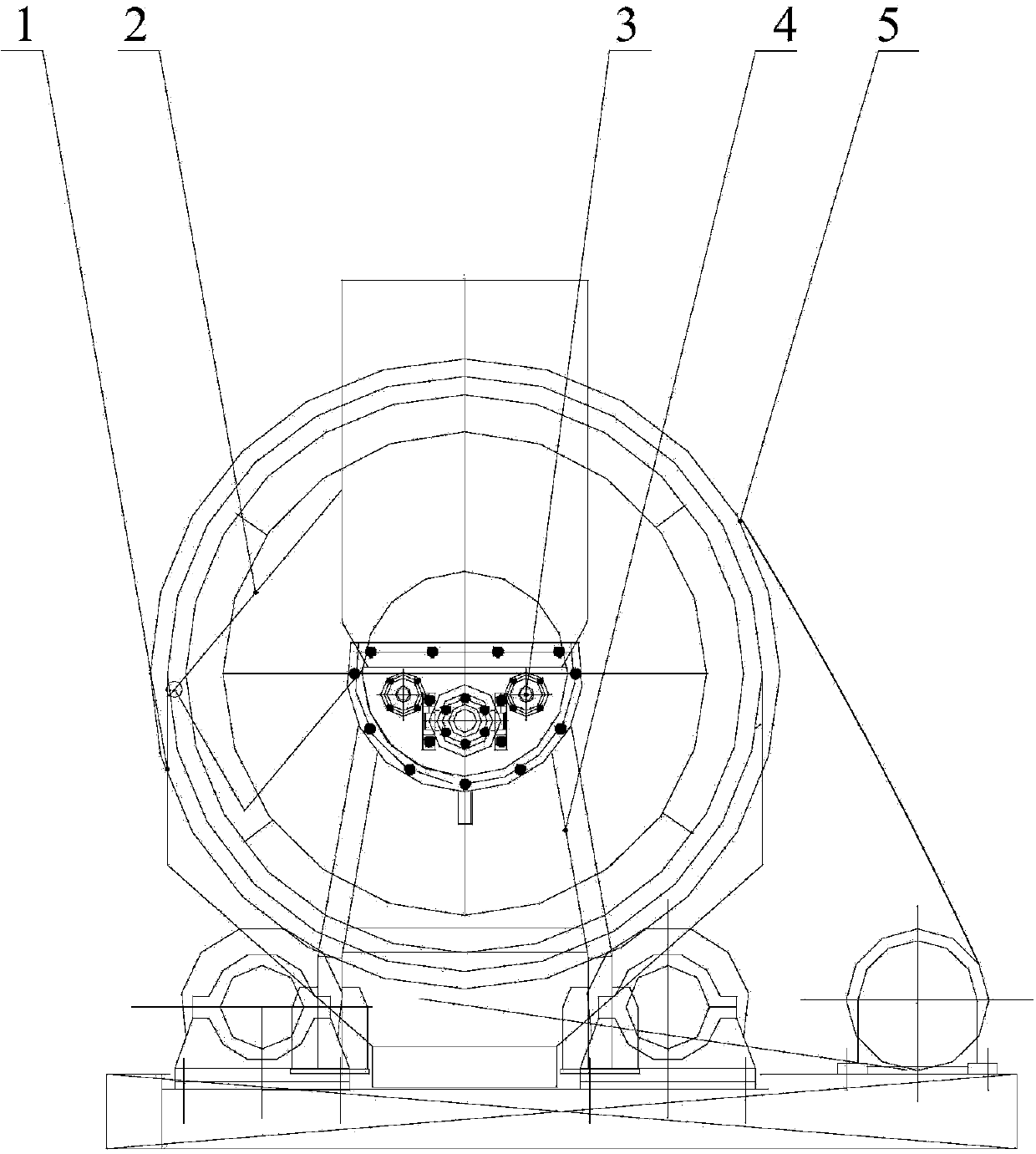

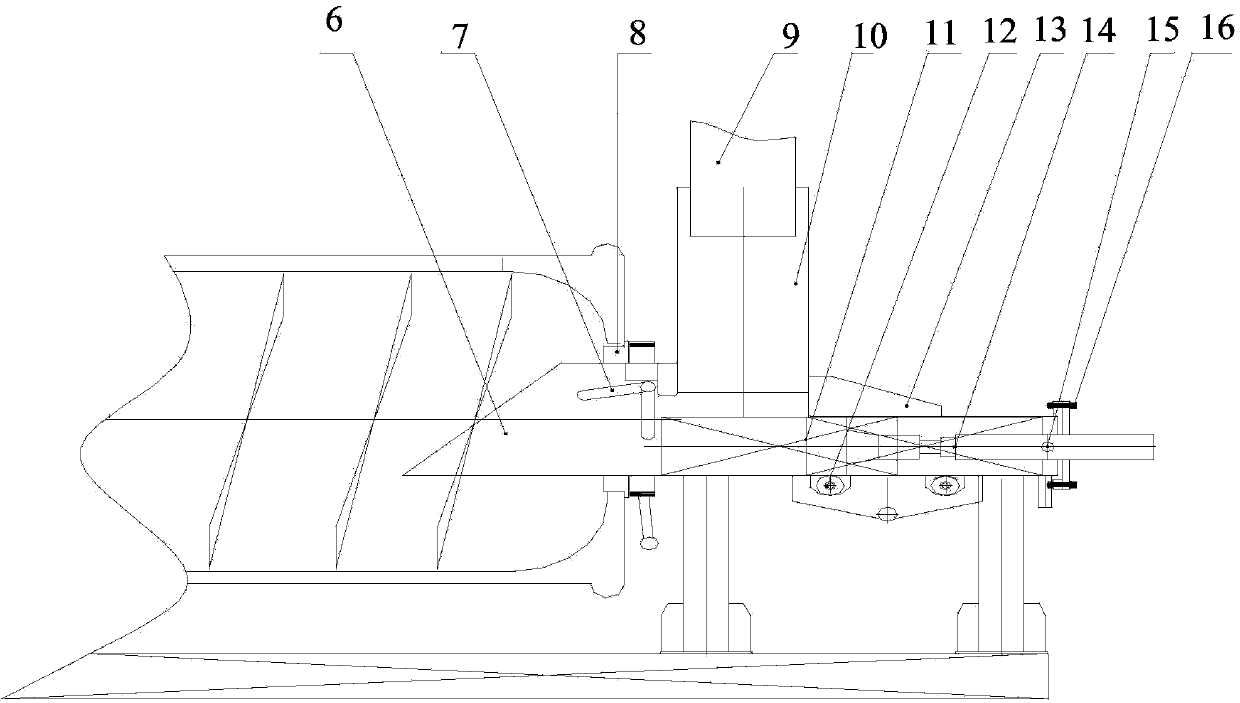

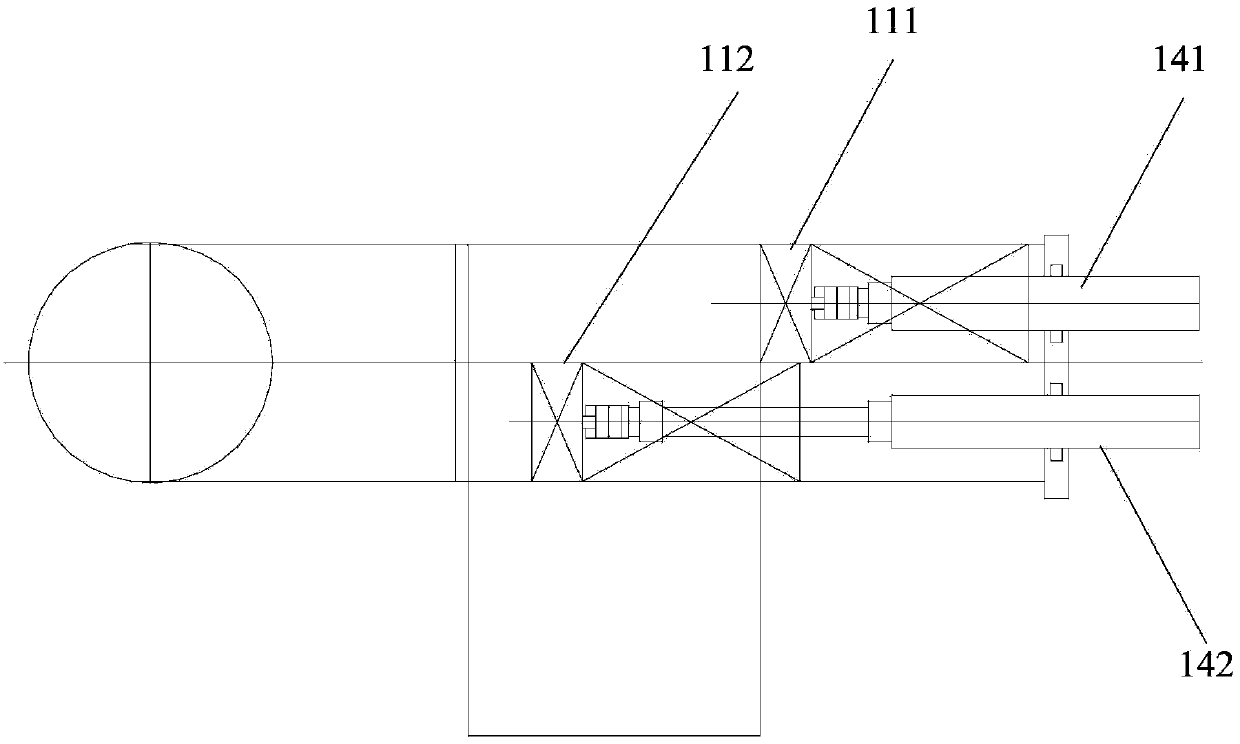

[0050] In the embodiment of the feeding device used in the slag cooling machine of the fluidized bed garbage incinerator, the push box assembly includes a push box driving device and at least one push box; the push box is reciprocating along a straight line under the action of the push box driving device ; The push box assembly is connected with the boiler lower slag pipe of the fluidized bed garbage incinerator, and is used to receive the material from the boiler lower slag pipe and push the material to the slag cooler.

[0051] Compared with the free falling of materials, because of the forced conveying of one, two or more push boxes, the red-hot iron wire and molten glass soft ash are forcibly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com