Novel frequency conversion system for thermal power plant

A technology for thermal power plants and frequency conversion systems, applied in control systems, control generators, electrical components, etc., can solve problems such as hindering promotion and high prices, and achieve high internal efficiency, less land occupation, and increased driving power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

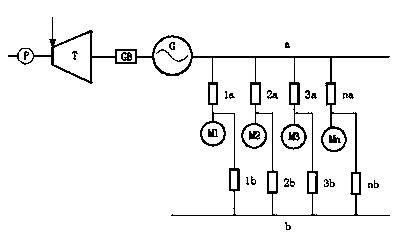

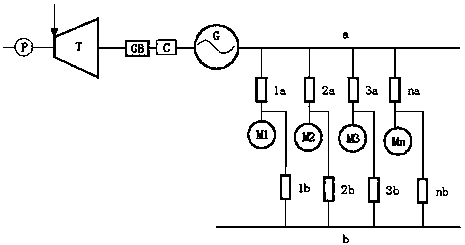

[0036] like figure 2 As shown, another specific embodiment of a new frequency conversion system of the present invention for a thermal power plant includes a steam turbine T, a feed water pump P, a generator G, a transmission gearbox GB, a clutch C, a frequency conversion bus a and a power frequency Busbar b. Auxiliary M 1 ,M 2 ,M 3 ... M n It is connected to the frequency conversion bus a through the switches 1a, 2a, 3a,..., na, and connected to the power frequency bus b through the switches 1b, 2b, 3b..., nb. As the unit load changes, the steam extraction volume and parameters entering the steam turbine will change accordingly, and the speed of the steam turbine will change synchronously, thereby changing the speed of the feed water pump on the one hand, and changing the frequency of the alternating current output by the generator on the other hand. This generator provides frequency conversion power supply for all auxiliary machines connected to the frequency conversio...

specific Embodiment approach 3

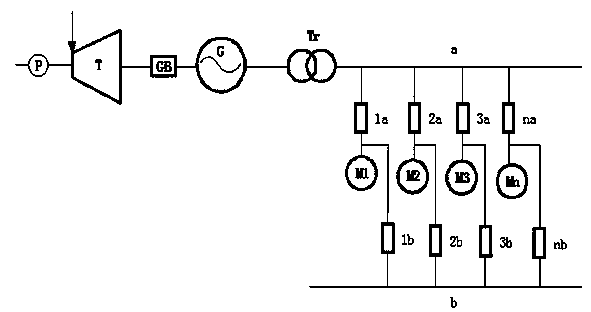

[0039] like image 3 As shown, another specific embodiment of a novel frequency conversion system for a thermal power plant of the present invention includes a steam turbine T, a feed water pump P, a generator G, a variable speed gearbox GB, a double-winding transformer Tr, a frequency conversion bus a and Power frequency bus b. Auxiliary M 1 ,M 2 ,M 3 ... M n It is connected to the frequency conversion bus a through the switches 1a, 2a, 3a,..., na, and connected to the power frequency bus b through the switches 1b, 2b, 3b..., nb. As the unit load changes, the steam extraction volume and parameters entering the steam turbine will change accordingly, and the speed of the steam turbine will change synchronously, thereby changing the speed of the feed water pump on the one hand, and changing the frequency of the alternating current output by the generator on the other hand. This generator provides frequency conversion power supply for all auxiliary machines connected to the ...

specific Embodiment approach 4

[0042] like Figure 4 As shown, another specific embodiment of a novel frequency conversion system used in a thermal power plant of the present invention includes a steam turbine T, a feed water pump P, a generator G, a variable speed gearbox GB, a double-winding transformer Tr, a frequency conversion bus a, Power frequency bus b, frequency conversion bus c, power frequency bus d. Auxiliary M 1 ,M 2 ,M 3 ... M n It is connected to the frequency conversion bus a through switches 1a, 2a, 3a,..., na, and connected to the power frequency bus b through switches 1b, 2b, 3b..., nb; the auxiliary machine M 1 ’, M 2 ’, M 3 ’…M n ’ is connected to the frequency conversion bus c through switches 1c, 2c, 3c,..., nc, and connected to the power frequency bus d through switches 1d, 2d, 3d..., nd. As the unit load changes, the steam extraction volume and parameters entering the steam turbine will change accordingly, and the speed of the steam turbine will change synchronously, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com