Quantitative table salt and preparation method thereof

A salt and weight technology, applied in food preparation, food science, food forming, etc., can solve the problems of low production efficiency, large mold limit, high production cost, etc., and achieve high production efficiency, low production cost, and easy preservation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

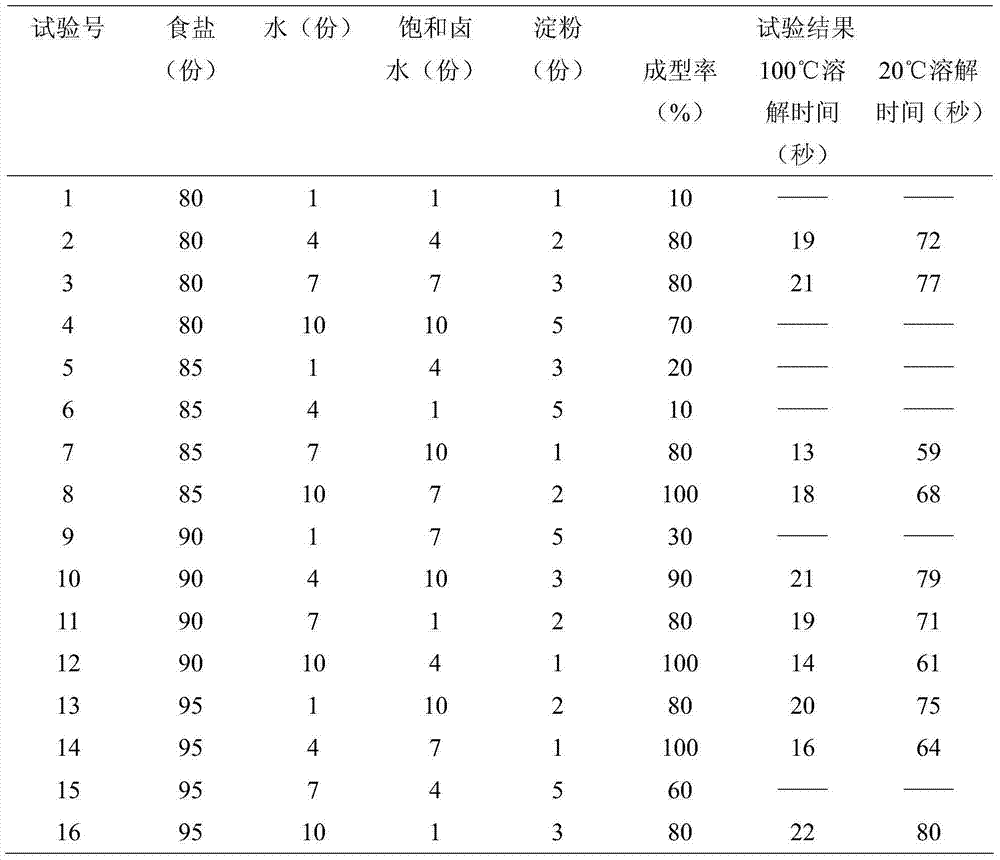

[0021] In order to understand the influence of different components in the formula on the molding rate and solubility of the finished product, and to obtain a better formula, four factors and four levels of orthogonal experiments are used to optimize the formula to make 1g of quantitative salt, and then extruded through the sealed automatic gap forming equipment , the tunnel drying equipment is dried into a cube-shaped (length*width*height: 16mm*8mm*6mm) finished product. Through 16 sets of orthogonal tests, 10 samples are made for each set of tests, and the molding rate is greater than or equal to 80%. Solubility test of the sample: Dissolving operation at 100°C and 20°C respectively at a certain stirring speed, compared with the dissolution time of 1g of bulk salt under the same conditions (10 seconds at 100°C, 55 seconds at 20°C), the specific results are shown in the table 1:

[0022] Table 1 The relationship between quantitative salt molding rate, dissolution time and tes...

Embodiment 2

[0025] Embodiment 2 A kind of preparation method of quantitative table salt, it comprises the steps:

[0026] (1) crushing: the salt is crushed to 100 mesh;

[0027] (2) Mixing: Mix 90 parts of table salt, 4 parts of saturated brine, 6 parts of water and 1 part of carrageenan;

[0028] (3) Molding: put the mixture mixed in step (2) into a 1g cylindrical mold or molding equipment, and make a cylindrical semi-finished product as required, specifically height: 3.5mm, diameter: 16mm;

[0029] (4) drying: the cylindrical semi-finished product obtained in step (3) is sent into a tunnel dryer, and dried to a water content of 1%, to obtain a quantitative salt product of 1 g / block.

Embodiment 3

[0030] Embodiment 3 A kind of preparation method of quantitative table salt, it comprises the steps:

[0031] (1) crushing: the salt is crushed to 80 mesh;

[0032] (2) Mixing: Mix 86 parts of table salt, 5 parts of saturated brine, 4 parts of water and 1 part of gelatin;

[0033] (3) Forming: put the mixture mixed in step (2) into a 2g cylindrical mold or molding equipment, and make a cylindrical semi-finished product as required, specifically height: 7mm, diameter: 16mm;

[0034] (4) drying: the cylindrical semi-finished product obtained in step (3) is sent into a tunnel dryer, and dried to a water content of 1.5%, to obtain a quantitative salt product of 2 g / block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com