Preparation method for PtCu/C catalyst

A catalyst, sodium borohydride technology, is applied in the field of preparation of PtCu/C catalysts, which can solve the problems of easy agglomeration of PtCu nanoparticles and easy oxidation of Cu nanoparticles, and achieve the effects of preventing oxidation, preventing aggregation and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

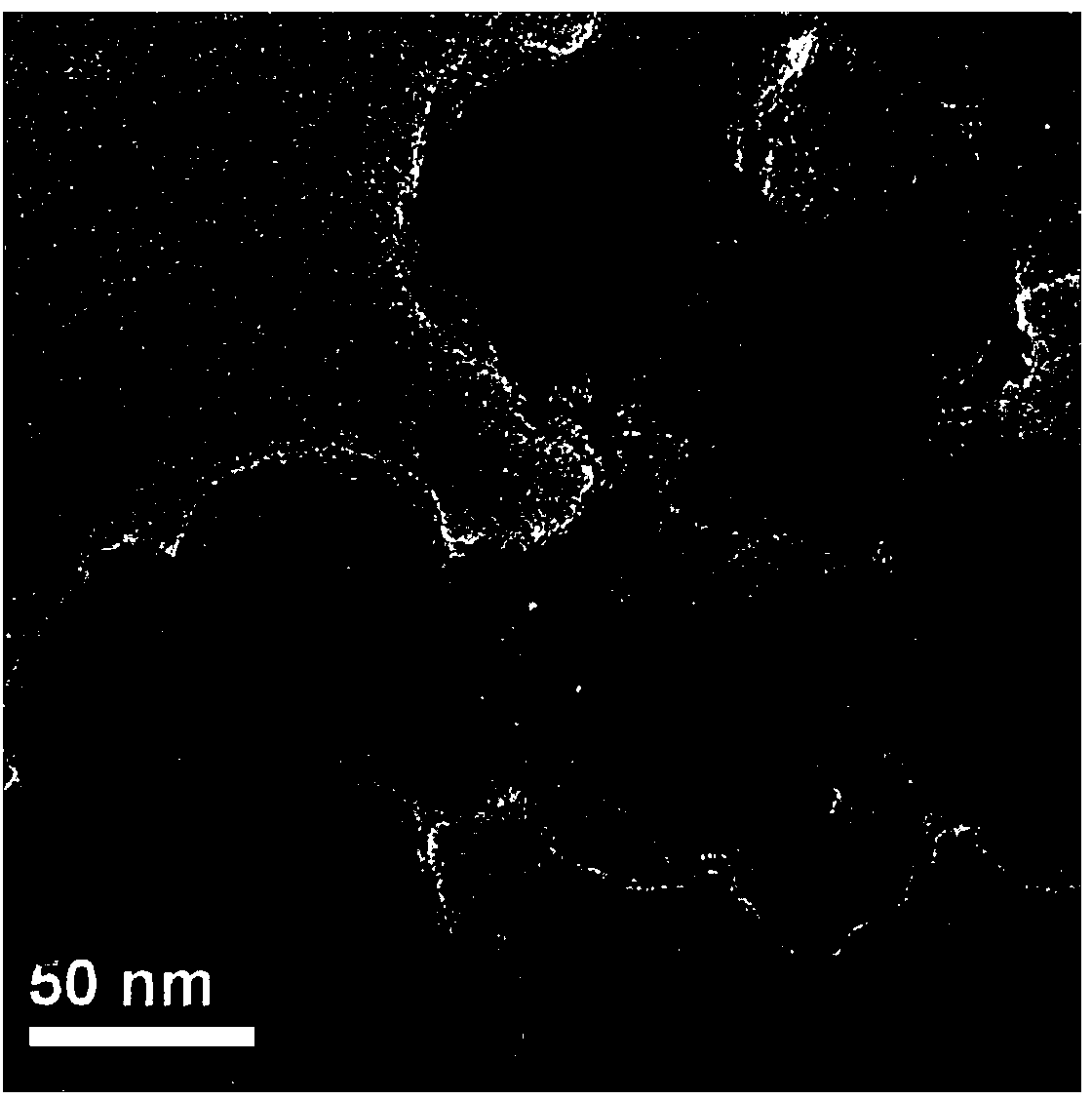

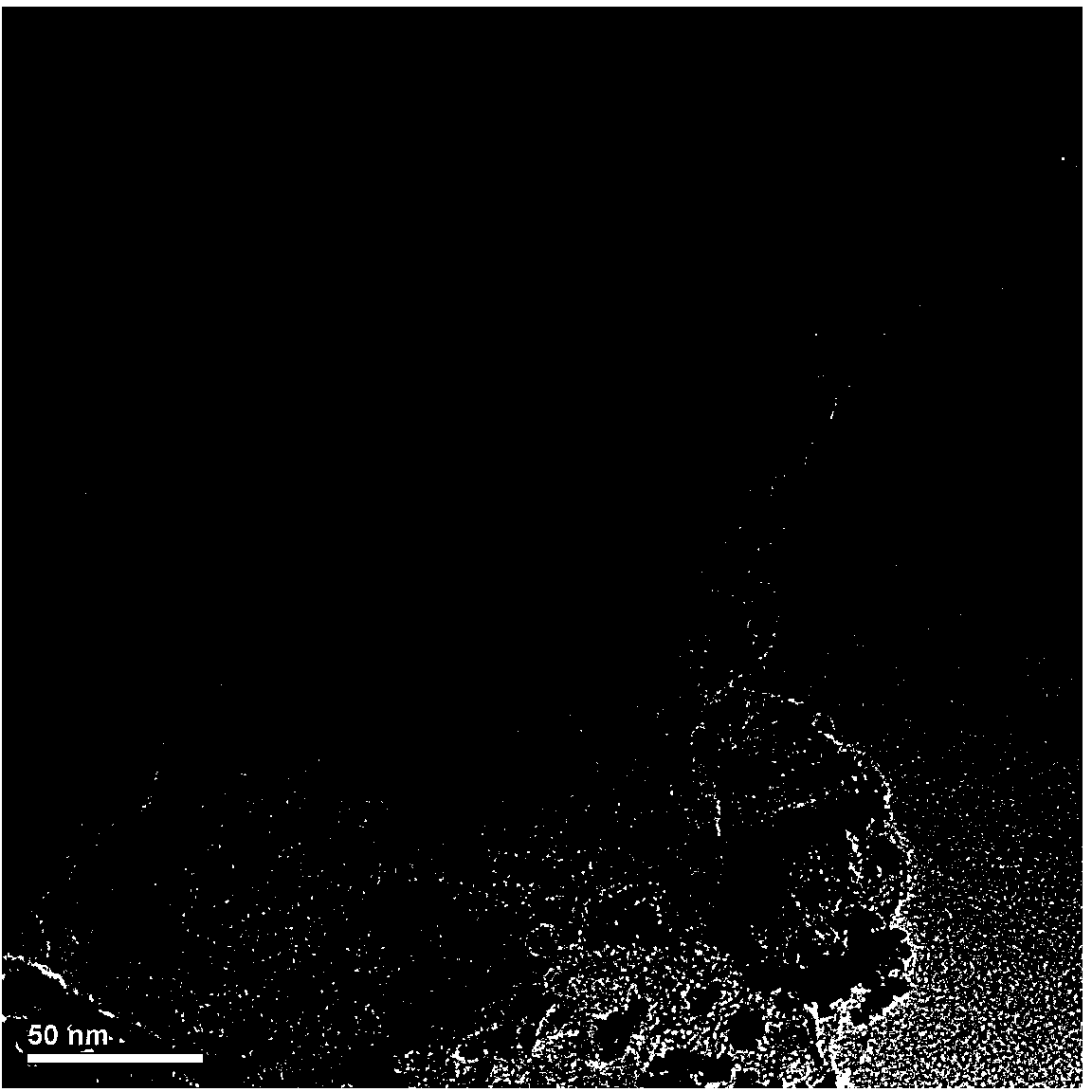

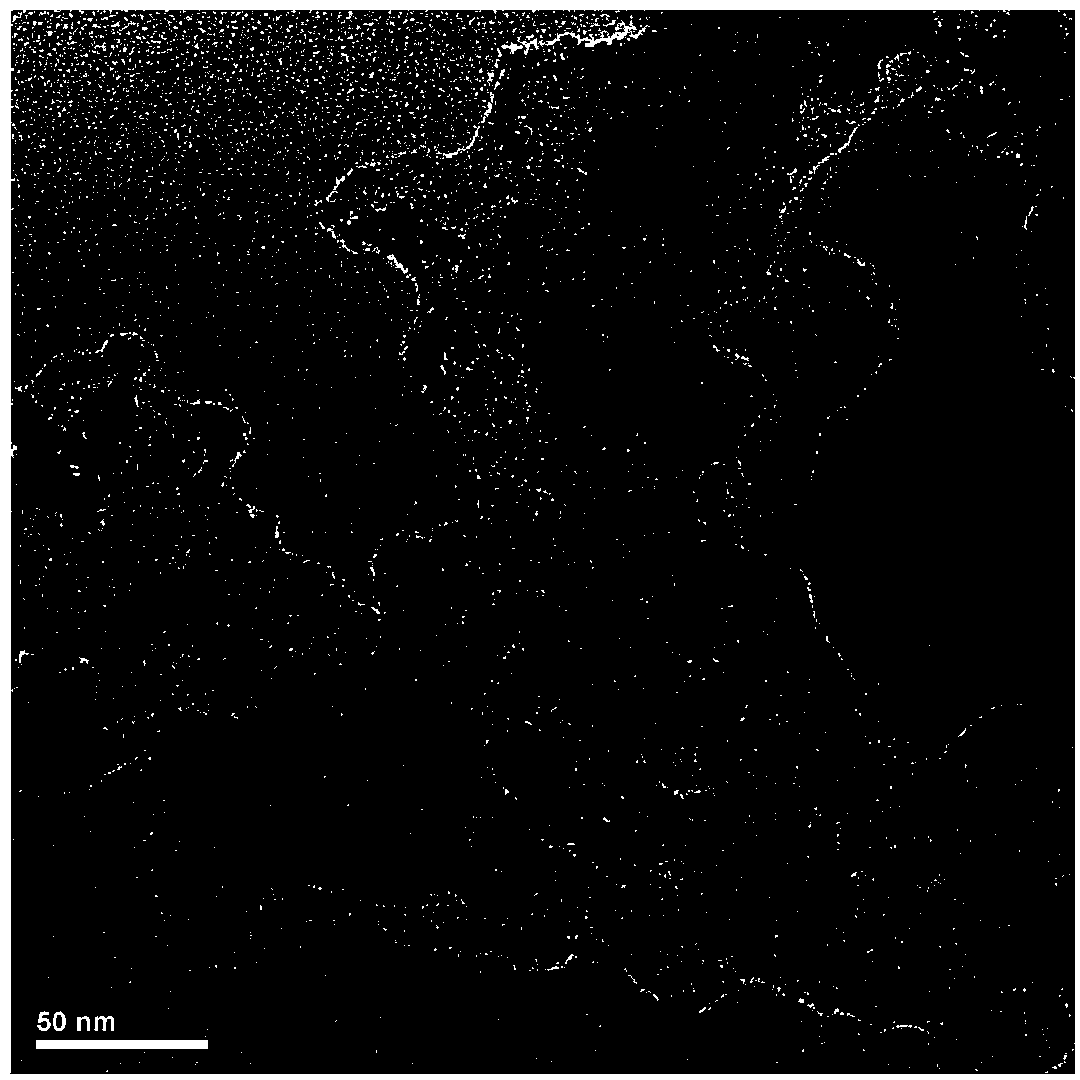

Image

Examples

preparation example Construction

[0027] The present invention provides a kind of preparation method of PtCu / C catalyst, comprising:

[0028] Step 1: mixing the copper source and the carbon carrier in the solution to obtain a suspension;

[0029] Step 2: Under the protection of argon, mix the suspension obtained in Step 1 with sodium borohydride, and then add citric acid solution to obtain a mixed solution;

[0030] Step 3: Mix the mixed solution obtained in Step 2 with a platinum source to obtain a PtCu / C catalyst.

[0031] According to the present invention, in step 1, the copper source and the carbon carrier are first mixed in the solution, the carbon carrier is first added to deionized water and stirred evenly, preferably dispersed by ultrasonic for 1-2h, and then the copper source is added to obtain Suspension; the carbon carrier is a carbon carrier well known to those skilled in the art, without special limitations, preferably activated carbon, carbon nanotubes or graphene, more preferably VulcanXC-72 o...

Embodiment 1

[0042] 1) Add 96mg of VulcanXC-72 into 120mL of deionized water, ultrasonically disperse for 1 hour, then add 24mL of 0.01MCuCl 2 aqueous solution to obtain a suspension;

[0043] 2) Bubble argon into the suspension in 1) for 1 hour to remove the oxygen in the solution, and then add 12 mL containing 18.64 mg of NaBH 4 The aqueous solution, let stand for 3h, then add 24mL0.005M citric acid aqueous solution (molar ratio CuCl 2 : citric acid=1:0.5), obtain mixed solution;

[0044] 3) Add 24mL of 0.005M H to the mixture in 2) 2 PtCl 6 For the aqueous solution, the temperature of the water bath was controlled at 30° C., and the stirring was continued for 12 hours. The obtained mixed solution was filtered, washed, and vacuum-dried at 60° C. to obtain a PtCu / C catalyst.

[0045] Add 5 mg of the above-mentioned PtCu / C catalyst to 50 μL of the Nafion solution produced by Ladrich with a mass concentration of 5%, and disperse it ultrasonically for 30 minutes to obtain a solution; tak...

Embodiment 2

[0047] 1) Add 96mg of VulcanXC-72 into 120mL of deionized water, ultrasonically disperse for 1 hour, then add 24mL of 0.01MCuCl 2 aqueous solution to obtain a suspension;

[0048] 2) Bubble argon into the suspension in 1) for 1 hour to remove the oxygen in the solution, and then add 12 mL containing 18.64 mg of NaBH 4 The aqueous solution was left to stand for 3h, and then 24mL of 0.01M citric acid aqueous solution (molar ratio CuCl2:citric acid=1:1) was added to obtain a mixed solution;

[0049] 3) Add 24mL of 0.005M H to the mixture in 2) 2 PtCl 6 For the aqueous solution, the temperature of the water bath was controlled at 30° C., and the stirring was continued for 12 hours. The obtained mixed solution was filtered, washed, and vacuum-dried at 60° C. to obtain the PtCu / C catalyst.

[0050] Add 5 mg of the above-mentioned PtCu / C catalyst to 50 μL of the Nafion solution produced by Ladrich with a mass concentration of 5%, and disperse it ultrasonically for 30 minutes to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com