Manufacturing device and method for injection mold with conformal cooling pipeline

A technology of conformal cooling and injection molding, which is applied in the field of mold manufacturing, can solve the problems of metal powder blockage in pipeline arrangement, reduce cooling effect, rough inner wall of pipeline, etc., and achieve the effect of improving effective flow and cooling capacity, and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

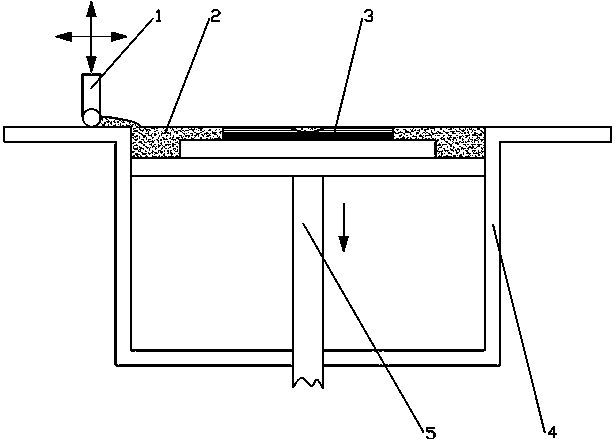

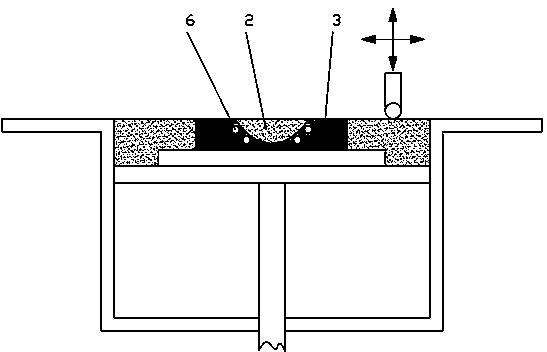

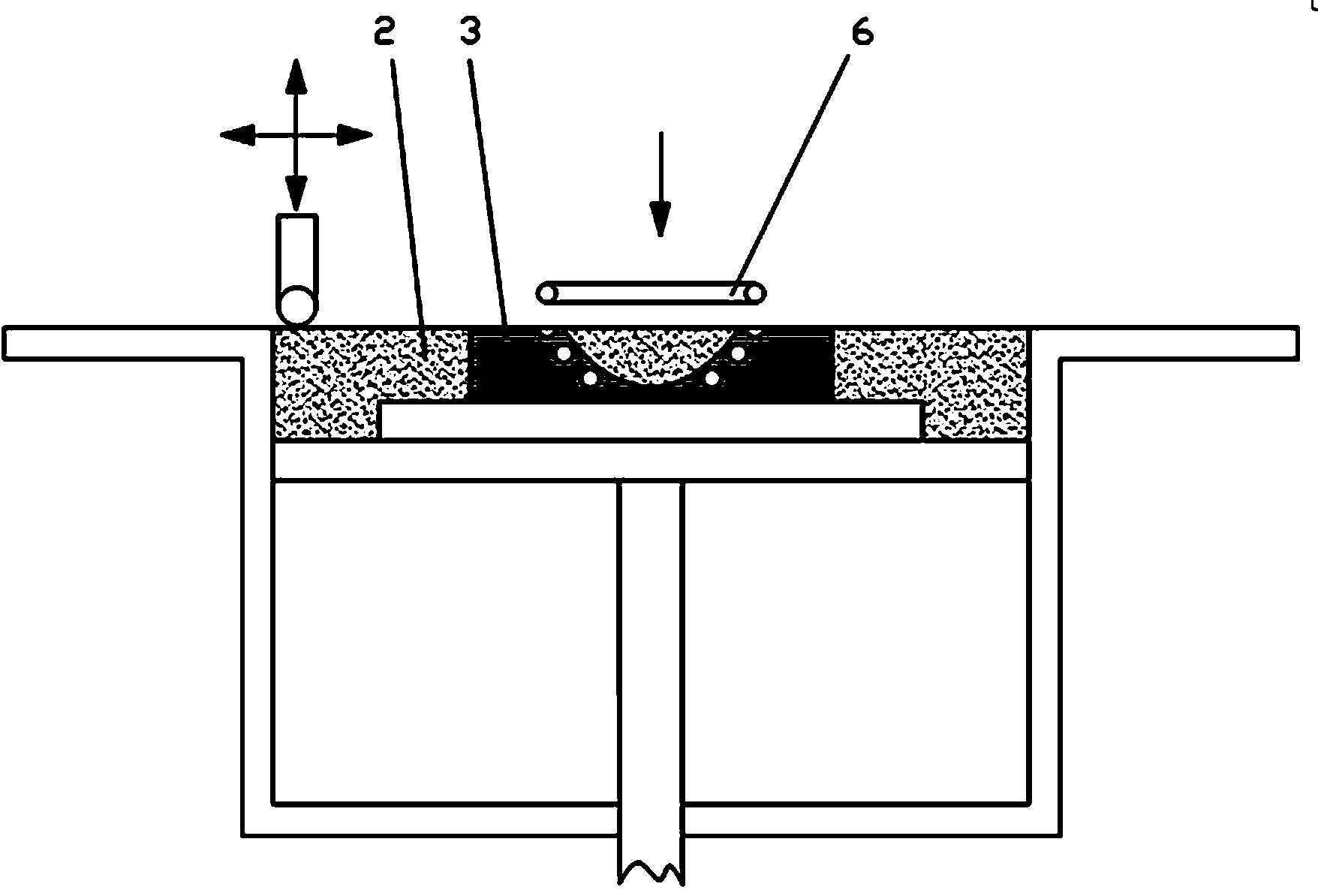

[0032] Such as figure 1 As shown, an injection mold manufacturing device with a conformal cooling pipeline includes selective laser melting equipment, and the selective laser melting equipment includes a laser scanning system, a powder feeding mechanism, a molding working chamber 4, a lifting table 5, a flexible The powder spreading and leveling device 1, the lifting platform 5 is set in the forming working chamber 4 and can move up and down, the flexible powder spreading and leveling device 1 is movable above the forming working chamber 4 and can move horizontally and vertically Moving, the flexible powder spreading and scraping device 1 can lift up a certain distance by itself when it is in contact with the protruding part of the conformal cooling pipe 6 during the horizontal powder spreading and scraping process, and cross the contour of the conformal cooling pipe 6 After the protruding part, it can drop to the original height by itself to ensure the smooth progress of the ...

Embodiment 2

[0035] A method for manufacturing an injection mold with a conformal cooling pipeline, comprising the steps of:

[0036] Step 1. Through the selective laser melting technology based on layered manufacturing principle, the laser beam of the laser scanning system is controlled to act on the metal powder in the area to be formed to form a part of the mold cavity entity 3 (see figure 1 ), according to the physical performance requirements of the mold cavity entity, select appropriate metal powder as the raw material for mold manufacturing, such as austenitic stainless steel, nickel-based alloy, cobalt-chromium alloy, etc.;

[0037] Step 2. Process a semicircular groove for embedding the conformal cooling channel 6 at a moderate height inside the mold cavity entity 3 through selective laser melting technology based on the layered manufacturing principle, and then clean out the metal in the groove powder, and then put the conformal cooling pipe 6 into the semicircular groove accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com