Automobile spare tire cover plate and its processing technology and processing equipment

A technology of automobile spare tire cover and processing technology, which is applied in spare tire arrangement, vehicle components, lamination and other directions, can solve the problems of high cost, many processes, complicated operation, etc., and achieves low cost, reduced product weight, and reduced use. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 A car spare tire cover

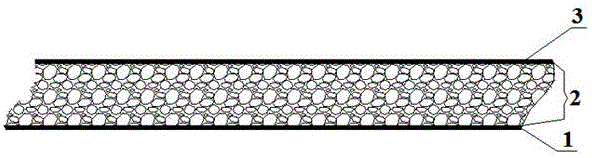

[0041] Such as figure 1 As shown, the automobile spare tire cover plate of the present embodiment is a three-layer composite layer structure along its thickness direction, including a mixture layer 2 of rigid polyurethane and fiber formed by high-pressure foaming and spraying as the core, and a high-pressure foaming spray-molded mixture layer 2 respectively. The first hard polyurethane surface layer 1 and the second hard polyurethane surface layer 3 are formed by foaming and spraying on both sides of the core. in,

[0042] The fiber is glass fiber (it can also be hemp fiber, man-made fiber or synthetic fiber, or a mixture of two or more of glass fiber, hemp fiber, man-made fiber and synthetic fiber, depending on the type of fiber in this case) equipped with a corresponding number of fiber cutters).

Embodiment 21—27

[0043] Embodiment 21-27 A kind of processing technology of automobile spare tire cover plate

[0044]

[0045]

[0046]Embodiments 21-27 are respectively a process for processing the spare tire cover of an automobile, which are used to process the product of Embodiment 1. They are carried out in the following order respectively:

[0047] ①Use a high-pressure foaming machine to spray the rigid polyurethane at 22-28°C to the lower mold of the mold to form the first rigid polyurethane surface layer 1 with a gram weight of 200-500g / m 2 ;

[0048] ② The rigid polyurethane at 22-28°C is sprayed onto the first rigid polyurethane surface layer 1 with a high-pressure foaming machine, and the chopped fibers are sprinkled at the same time, so that the rigid polyurethane and the fibers are fully infiltrated or partially soaked when spraying. Infiltration, after reaching the first hard polyurethane surface layer 1, it is completely infiltrated (the final realization of full infiltr...

Embodiment 3

[0058] Embodiment 3 A kind of processing equipment of automobile spare tire cover plate

[0059] The processing equipment of the present embodiment is used for processing the product of embodiment 1, and its work process can realize the technology of embodiment 21-27.

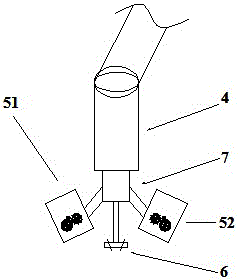

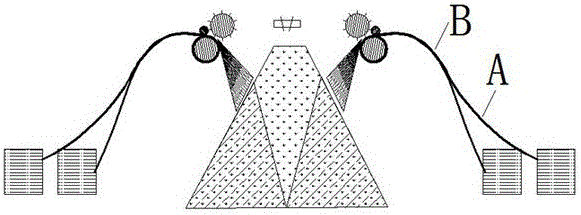

[0060] The present embodiment comprises mechanical arm 4 under main program control, two fiber cutting machines 51 and 52 (sprinkle into one or two kinds of fibers and join two; If want to spread into more kinds of fibers at the same time, then need to be equipped with corresponding number fiber cutting machine), high-pressure foaming rigid polyurethane spraying machine, mould, molding press and mold temperature controller, among which:

[0061] The two fiber cutting machines 51 and 52 are independent devices, and have bolts for connecting external devices, so that the installation angle can be adjusted freely.

[0062] The two sides of the spraying head 6 respectively located in the high-pressure foaming rigi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com