Vanadium dioxide-graphene compound and its use as lithium ion battery positive electrode material

A lithium-ion battery and graphene composite technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor conductivity and poor cycle performance, and achieve high conductivity, large specific capacity, and excellent high-rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A vanadium dioxide-graphene composite, which is prepared through the following steps:

[0039] (1) Mix 1800mg of vanadium pentoxide and 400mg of graphene oxide (the mass ratio of the two is 4.5:1), disperse them into 200mL of water, then seal them in a hydrothermal kettle, and react at 180±5°C for 12 hours about;

[0040] (2) Add 2-10mL (35wt%) hydrazine hydrate to the system after step (1), and carry out the reduction reaction at 80±2°C for about 5 hours;

[0041] (3) Freeze-dry at -40°C to obtain a solid product, which is a vanadium dioxide-graphene composite.

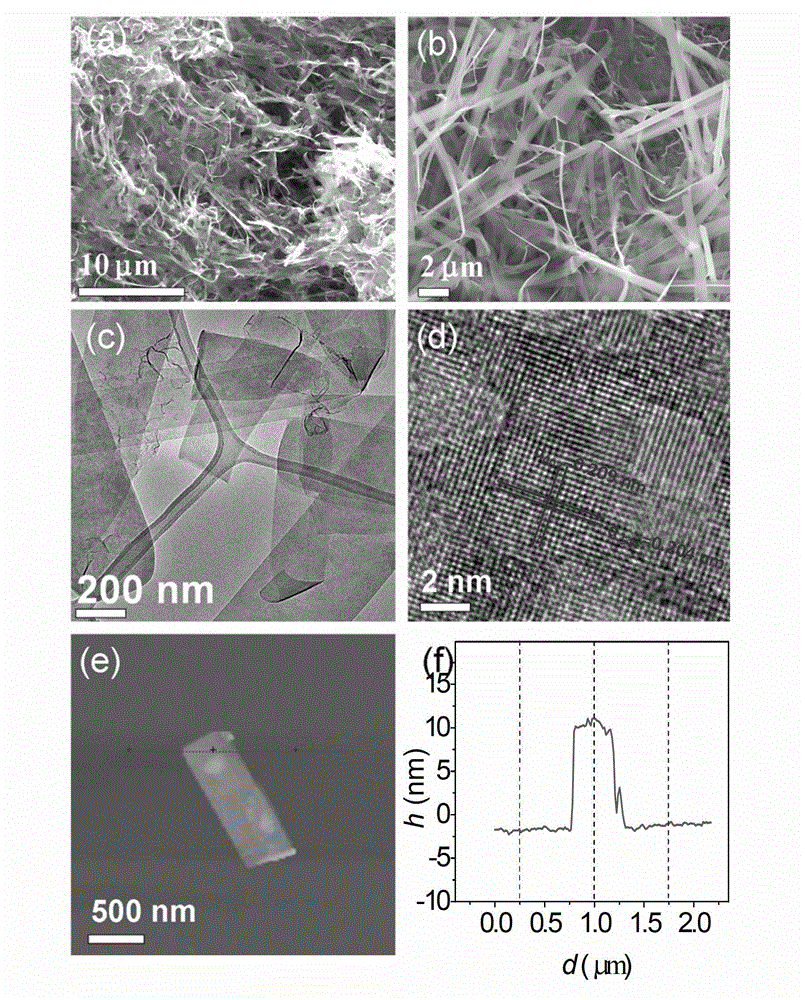

[0042] Characterize the morphology of the obtained vanadium dioxide-graphene composite, the results can be found in figure 1 . The vanadium dioxide-graphene composite is composed of vanadium dioxide-graphene composite strips with an average length of 1-100 μm, a width of 20-500 nm, and a thickness of 1-50 nm, with a specific surface area of 420 m 2 / g.

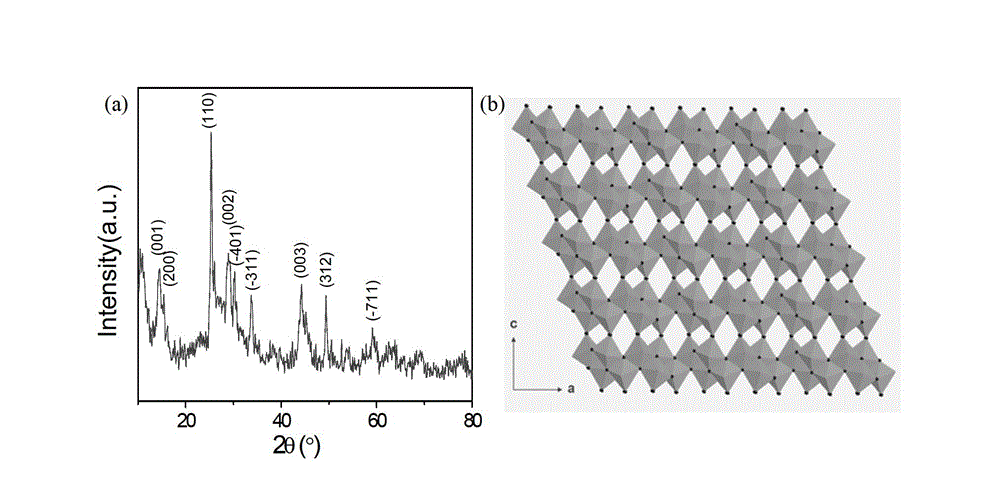

[0043] Characterize the structure of the vanadiu...

Embodiment 2

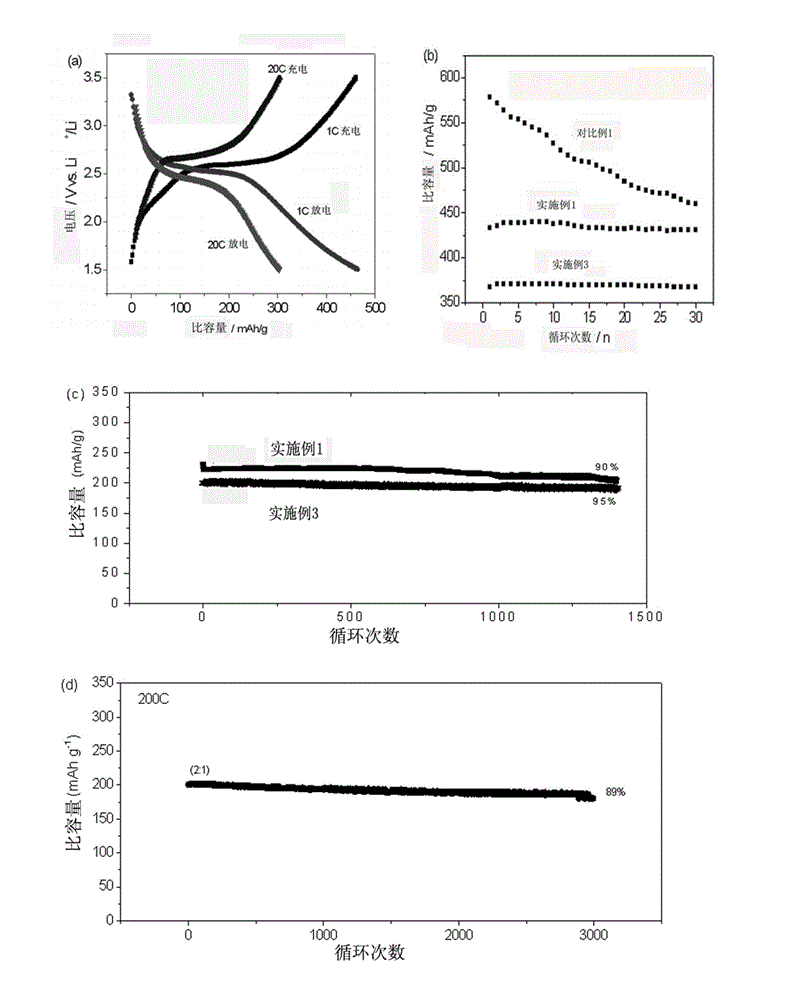

[0046] Embodiment 2 provides a vanadium dioxide-graphene composite, the preparation method of which is basically the same as that of Embodiment 1, except that the mass ratio of the raw material vanadium oxide to graphene oxide is 3:1. The vanadium dioxide-graphene composite is made into a working electrode according to the method provided by the present invention and the corresponding electrochemical performance test is carried out. The results are as follows: the first Coulombic efficiency is more than 90%, and when charging and discharging at 1C, the stable specific capacity is 390mAh / g; when charging and discharging at 20C, the stable specific capacity is 295mAh / g; when charging and discharging at 200C, the stable specific capacity is 204mAh / g; when charging and discharging at the above rate, the capacity can be maintained after 1400 repeated charging and discharging More than 90% of the initial capacity.

Embodiment 3

[0048] This example provides a vanadium dioxide-graphene composite, the preparation method of which is basically the same as in Example 1, except that the mass ratio of vanadium oxide and graphene oxide as raw materials is 2:1.

[0049] The vanadium dioxide-graphene composite is made into a working electrode according to the method provided by the present invention and the corresponding electrical performance test is carried out. The results are as follows: the first coulombic efficiency is 92%, and when charging and discharging at 1C, the stable specific capacity is 370mAh / g; when charging and discharging at 20C, the stable specific capacity is 284mAh / g; when charging and discharging at 200C, the stable specific capacity is 194mAh / g; and when charging and discharging at the above rate, the capacity can be maintained after 1400 repeated charging and discharging More than 92% of the original capacity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap