A kind of hot-melt non-adhesive nylon hook and loop fastener and its manufacturing method

A manufacturing method and technology of Velcro, applied in fasteners, textiles, papermaking, fabrics, etc., can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

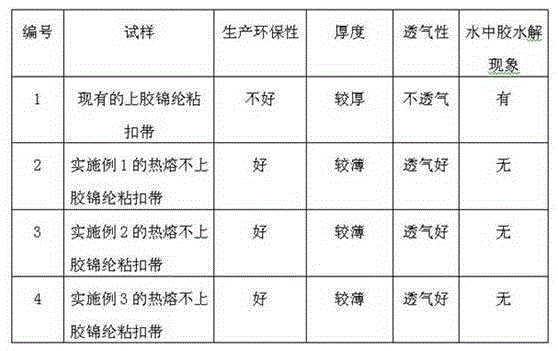

Examples

Embodiment 1

[0024] Step 1: Reasonably design the structure of the hook and loop fastener. The arrangement of the warp yarns in the fabric is 2 nylon multifilament warp yarns: 1 nylon hot-melt yarn monofilament warp yarn: 1 nylon monofilament hook yarn: 1 nylon hot-melt yarn single Silk warp yarns are arranged in such a cycle; the weft yarns in the fabric are arranged in the following way: 3 nylon multifilament weft yarns: 1 nylon hot-melt filament monofilament weft yarn, so circularly arranged.

[0025] Step 2: Optimize the raw material parameters of the hook and loop fastener. The linear density of the nylon multifilament warp yarn is 200D, the diameter of the nylon monofilament hook yarn is 0.15mm, the linear density of the nylon hot-melt monofilament is 50D, and the melting temperature is 70°C. The linear density of the multifilament weft yarn is 250D.

[0026] Step 3: Three pan heads are required for warping, one pan head for nylon hot-melt monofilament, one pan head for nylon monofil...

Embodiment 2

[0030] Step 1: Reasonably design the structure of the hook and loop fastener. The arrangement of the warp yarns in the fabric is 2 nylon multifilament warp yarns: 1 nylon hot-melt yarn monofilament warp yarn: 1 nylon monofilament hook yarn: 1 nylon hot-melt yarn single Silk warp yarns are arranged in such a cycle; the weft yarns in the fabric are arranged in the following way: 3 nylon multifilament weft yarns: 1 nylon hot-melt filament monofilament weft yarn, so circularly arranged.

[0031] Step 2: Optimizing the raw material parameters of the hook and loop, the linear density of nylon multifilament warp yarn is 230D, the diameter of nylon monofilament hook yarn is 0.20mm, the linear density of nylon hot-melt monofilament is 75D, and the linear density of nylon multifilament weft yarn for 280D.

[0032] Step 3: Three pan heads are required for warping, one pan head for nylon hot-melt monofilament, one pan head for nylon monofilament hook yarn, and one pan head for nylon multi...

Embodiment 3

[0036] Step 1: Reasonably design the structure of the hook and loop fastener. The arrangement of the warp yarns in the fabric is 2 nylon multifilament warp yarns: 1 nylon hot-melt yarn monofilament warp yarn: 1 nylon monofilament hook yarn: 1 nylon hot-melt yarn single Silk warp yarns are arranged in such a cycle; the weft yarns in the fabric are arranged in the following way: 3 nylon multifilament weft yarns: 1 nylon hot-melt filament monofilament weft yarn, so circularly arranged.

[0037] Step 2: Optimize the raw material parameters of the hook and loop fastener. The linear density of the nylon multifilament warp yarn is 260D, the diameter of the nylon monofilament hook yarn is 0.30mm, the linear density of the nylon hot-melt monofilament is 100D, and the linear density of the nylon multifilament weft yarn It is 300D.

[0038] Step 3: Three pan heads are required for warping, one pan head for nylon hot-melt monofilament, one pan head for nylon monofilament hook yarn, and on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com