Technology for decomposing waste industrial salt organic matter

A technology for industrial salt and organic matter, applied in the chemical industry, can solve the problems of high consumption, poor equipment operation continuity, rising production costs, etc., and achieve the effect of eliminating pollution, making full use of it and making huge profits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

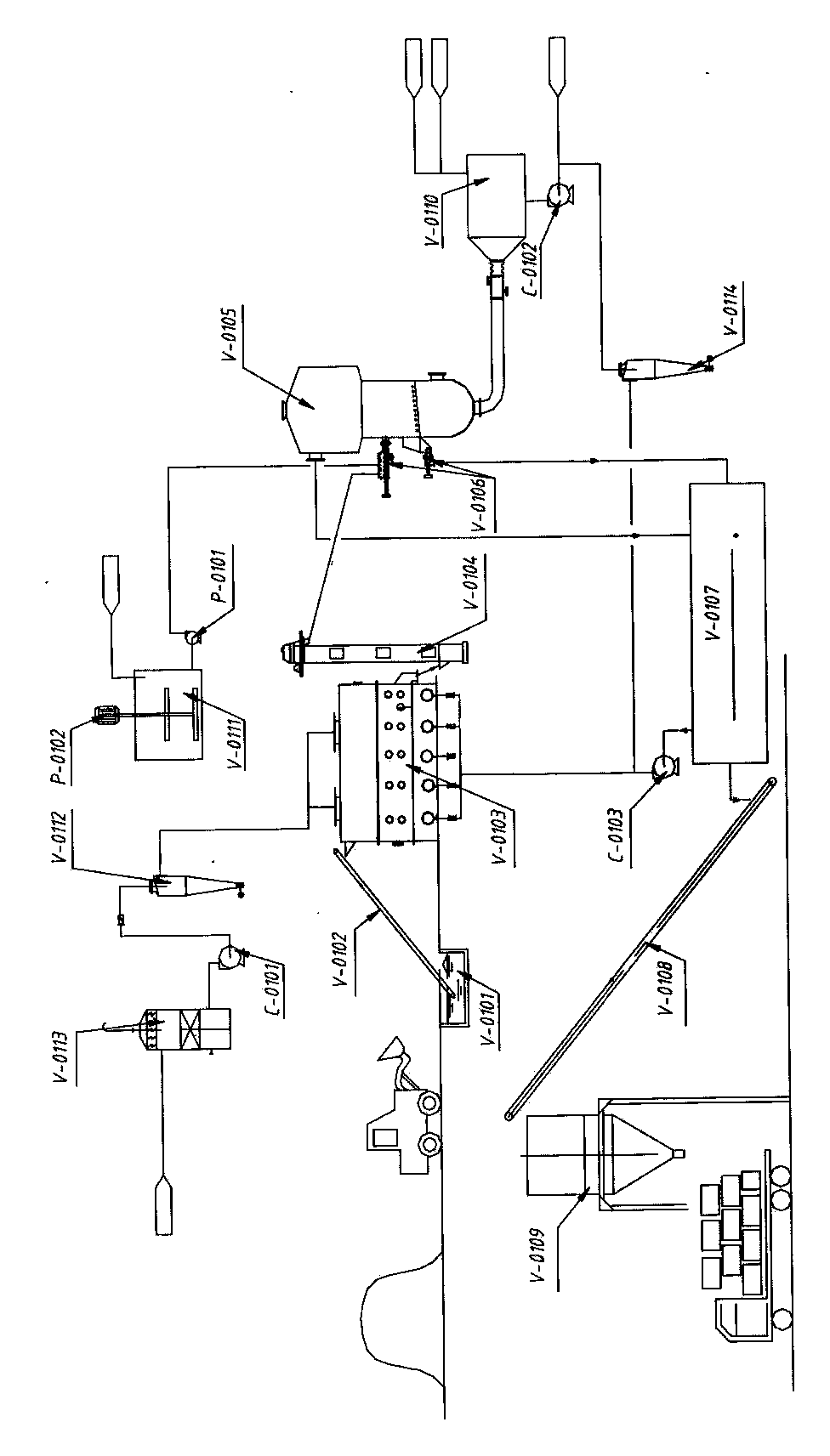

[0011] see figure 1 , this specific embodiment adopts the following technical scheme: the salt forklift shovels the waste industrial salt from the waste salt storage yard to the upper salt pond V-0101, and the waste industrial salt is evenly added to the upper salt pond V-0101 by the upper salt belt V-0102 to boil In the drying bed V-0103, the waste industrial salt is in gas-solid contact with the hot air entering the bottom of the drying bed in the boiling drying bed V-0103 to form a fluidized bed, and the hot air will be discarded in the boiling drying bed V-0103 The water in the industrial salt is completely dried and the salt is heated to about 85°C. The dried and heated waste industrial salt enters the bucket elevator V-0104 from the outlet of the boiling drying bed V-0103, and is lifted by the bucket elevator V-0104 To the feed port of industrial salt organic matter pyrolysis kettle V-0105, the catalyst required for the decomposition of organic matter is added to the cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com