Electric-arc-assisted laser welding-brazing method applicable to dissimilar material butt connection

A technology that assists lasers and dissimilar materials. It is applied in arc welding equipment, laser welding equipment, welding/welding/cutting items, etc. It can solve problems such as difficulty in obtaining qualified joints, liquid metal infiltration and spreading restrictions, and improve wetting and spreading. Performance, high-quality butt joints, the effect of improving joint performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

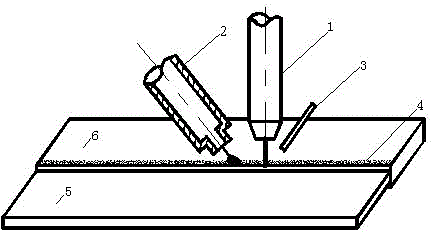

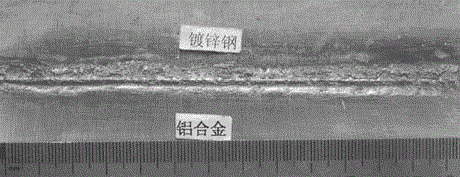

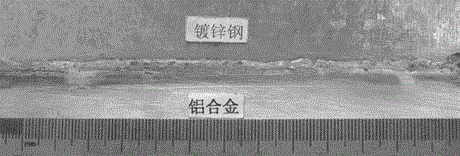

[0013] needle like figure 1 As shown, the present invention proposes an arc-assisted laser melting and brazing method for the butt joint of dissimilar materials, specifically a new process for connecting aluminum / steel dissimilar materials through an arc-assisted laser heat source. The method is to add a laser beam at a certain distance behind the laser beam Low-power auxiliary arc, the arc is separated from the laser (not recombined) and moves synchronously. The temperature field distribution of the welding process is changed by the auxiliary arc, the infiltration and spreading performance of the liquid metal is improved, and the high-quality connection of aluminum / steel dissimilar metals is obtained.

[0014] The invention is an arc-assisted laser melting and brazing method suitable for the butt joint of dissimilar materials, comprising the following steps:

[0015] (1) Wash the plate to be welded with acetone to remove the surface oil, and use mechanical grinding to remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com