Preparing method of picromerite by adopting mother liquor of potassium sulfate production by conversion method and sodium sulfate as raw materials

A technology of Magnesite and Potassium Sulfate, applied in the field of production technology for preparing Magnesite, and achieves the effects of high obtaining rate, less investment and less production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

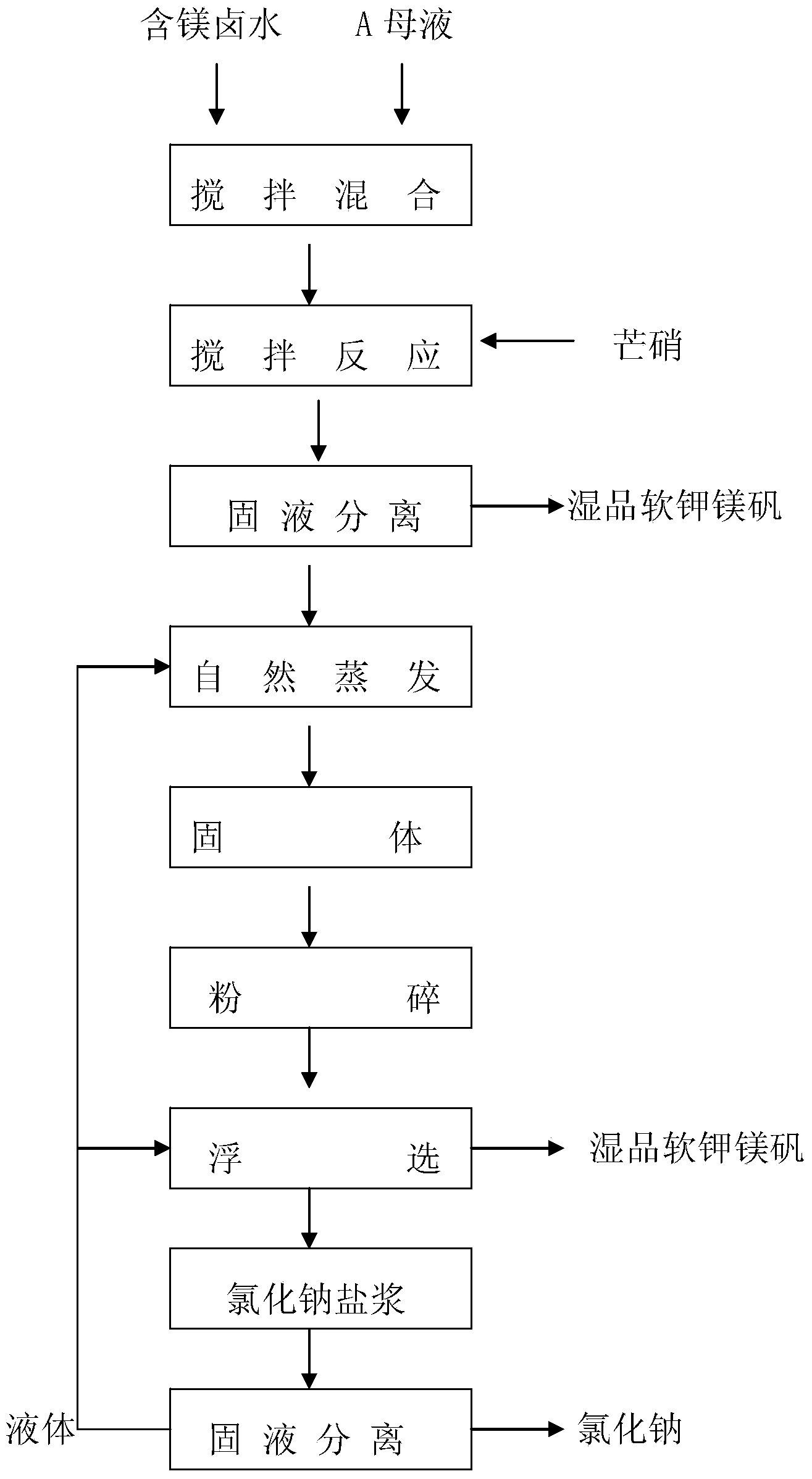

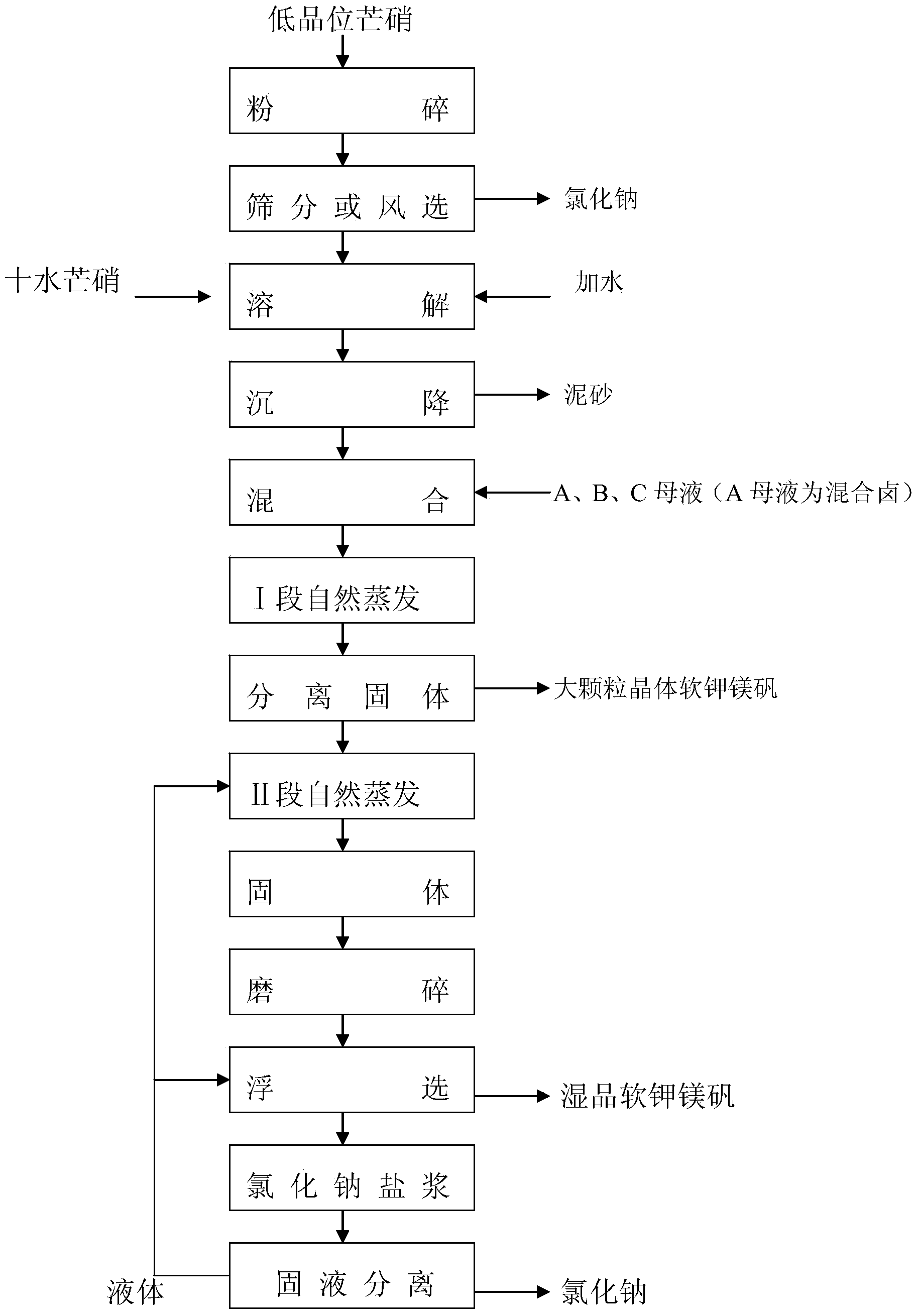

[0049] Embodiment 1: produce langbeinite with A mother liquor and Glauber's salt metathesis

[0050] Potassium sulfate mother liquor produced by potassium chloride and Glauber's salt, washing liquid when adding carnallite to produce potassium chloride, then adding Glauber's salt to produce kaleidite, potassium sulfate mother liquor, potassium chloride washing liquid, Glauber's salt composition are shown in Table 1, use K + 、Na + , Mg 2+ / SO 4 2- , Cl - ---H 2 The metastable phase diagram of the five-component system at 25°C is calculated, and the result of calculation is based on the composite point after mixing as the composition point of langbeinite: Glauber's salt 500g, potassium sulfate mother liquor: 1.07L, potassium chloride washing solution: 0.945L, after mixing, stir at 20-25°C, react for 2 hours, and carry out solid separation. The obtained solid 576g contains 15.21% of potassium ions, which is the wet product of langbeinite, and the recovery rate of potassium i...

Embodiment 2

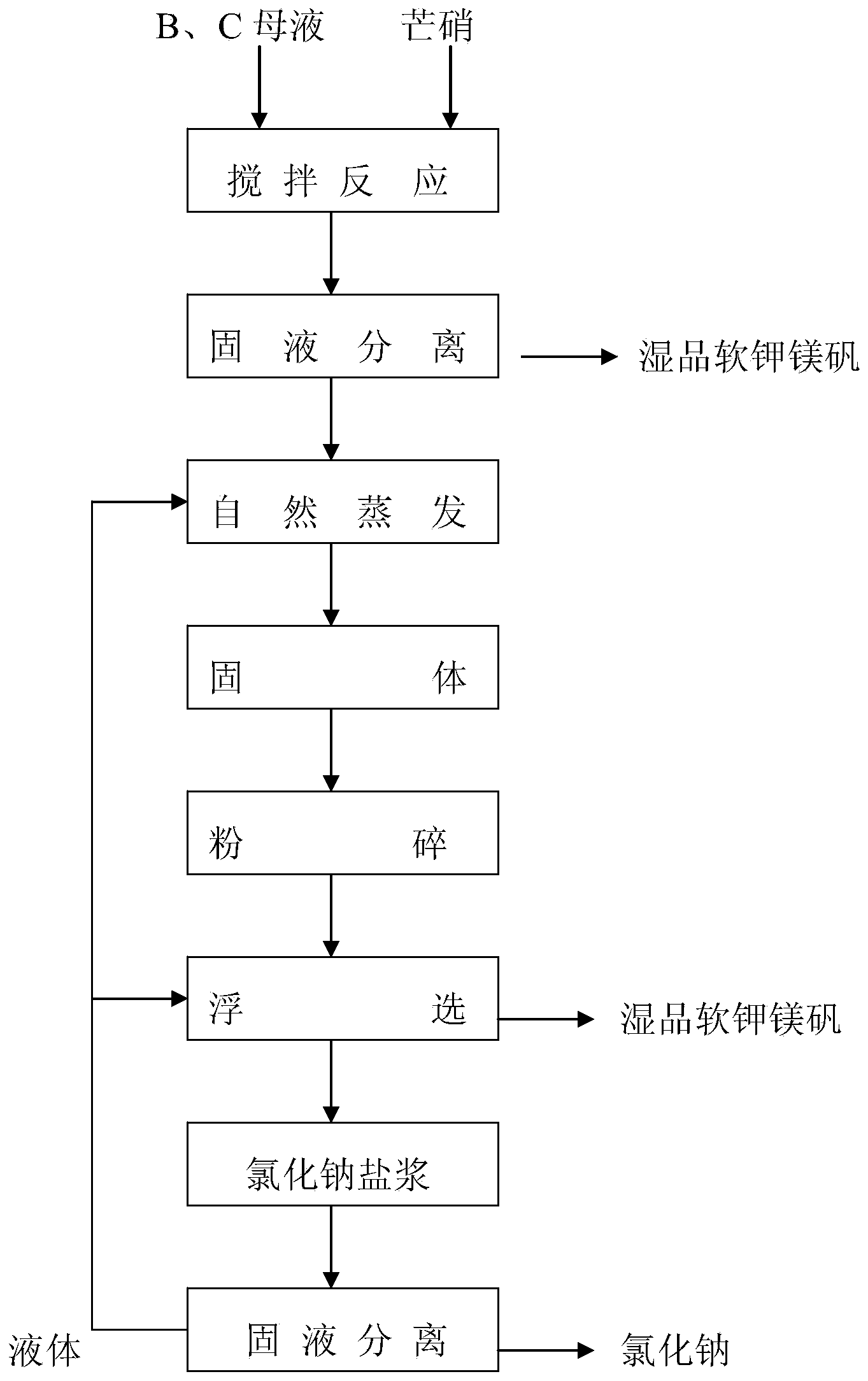

[0053] Embodiment 2: B mother liquor and Glauber's salt metathesis produce kaleinite

[0054] Potassium chloride and magnesium sulfate produce the mother liquor of potassium sulfate and Glauber's salt to produce langbeinite, the composition of potassium sulfate mother liquor and Glauber's salt are shown in Table 2, utilize K + 、Na + , Mg 2+ / SO 4 2- , Cl - ---H 2 The metastable phase diagram of the O quinary system at 25°C was calculated, and the result was calculated based on the composite point after mixing as the composition point of langbeinite: Glauber's salt: 500g, potassium sulfate mother liquor: 2.225L, after mixing, at 20 Stir at ~25°C, react for 2 hours, and carry out solid separation. The obtained solid is 580g, containing potassium ions: 16.63%. The composition of the langbeinite and sodium chloride saturated solution is shown in Table 2, and the mother liquor can continue to be evaporated to recover the lenbeinite.

[0055] Table 2

[0056]

Embodiment 3

[0057] Embodiment 3: C mother liquor and Glauber's salt metathesis produce kaleinite

[0058] Potassium sulfate mother liquor, Glauber's salt composition are shown in Table 3, utilize K + 、Na + , Mg 2+ / SO 4 2- , Cl - ---H 2 The metastable phase diagram of the O quinary system at 25°C is calculated, and the result of the calculation is based on the composite point after mixing as the composition point of langbeinite: Glauber's salt: 300g, potassium sulfate mother liquor: 1.160L, after mixing, at 20 Stir at a temperature of ~25°C, convert the reaction for 2 hours, and carry out solid separation. The obtained solid is 360g, containing potassium ions: 17.79%, which is the wet product of lenbeinite, and the recovery rate of potassium is 54.30%; the remaining mother liquor is 1.05L It is a saturated solution of langbeinite and sodium chloride, the composition of which is shown in Table 3, and the mother liquor can be continuously evaporated to recover lenbeinite.

[0059] ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com