Ship ballast water treating method

A technology of ship ballast water and treatment method, applied in the field of water treatment, can solve the problems of secondary pollution of sea water, large equipment volume, incomplete sterilization, etc., and achieve the effect of wide application scope, small equipment volume, and small negative impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

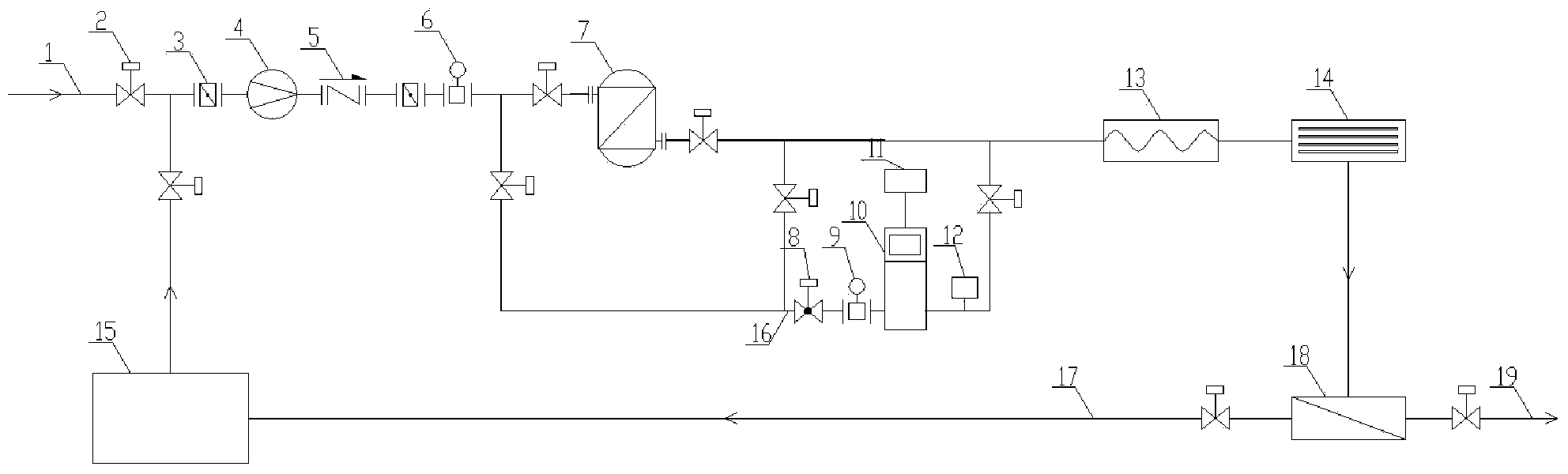

[0036] The ship ballast water treatment method of the present invention comprises the following steps:

[0037] 1) Filter the seawater prepared as ballast water through a 25 μm filter; to remove plankton and the like larger than 25 μm.

[0038] 2) Dissolve ozone in 10% of the filtered seawater to make 2-3mg / L ozone aqueous solution, and then mix it with the remaining 90% of seawater in the pipeline for ozone oxidation sterilization. The biochemical reaction time is 5-10 Second. The ozone is generated by an ozone generator that electrolyzes pure water to produce ozone, and the ozone is dissolved into the seawater by using a gas-liquid mixing pump to efficiently dissolve the ozone into the seawater.

[0039] 3) The seawater sterilized by ozone oxidation is subjected to ultrasonic cavitation sterilization with low-frequency sound waves with a frequency around 15 kHz; the ultrasonic waves are generated by ultrasonic transducers.

[0040] 4) The seawater sterilized by ultrasonic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com