A method for improving optical performance by introducing auxiliary ions into modified Si film

An optical performance and auxiliary technology, applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of low luminous efficiency, hindering thin films, and slow exciton fluorescence annihilation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

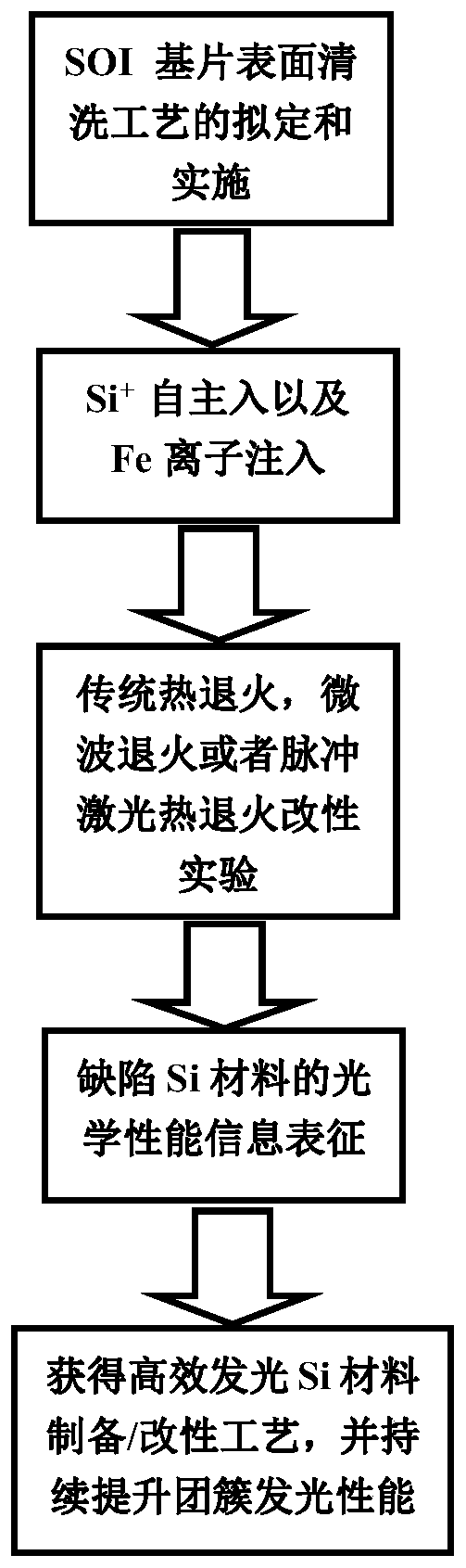

[0018] The method of introducing auxiliary ions into the modified Si film to improve the optical properties described in this example specifically includes the following steps:

[0019] (1) Select the SOI sheet of the P-type Si film with the top crystal orientation of (100), and clean it with the RCA standard cleaning method;

[0020] (2) Use an ion implanter to first implant the Si + The ions were implanted into the SOI silicon film layer, and the incident direction of the ions was 7° from the surface normal of the SOI silicon film, and was carried out in a vacuum room temperature environment. + The ion implantation dose is 2×10 17 cm -2 , the injection energy is 70keV;

[0021] (3) Si + After the ion implantation is completed, the iron ions are implanted into the layer, and the implantation dose is 1×10 15 cm -2 , the injection energy is 70keV. The ion incident direction is 7° from the surface normal of the SOI silicon film, and the ion implantation process is carried...

Embodiment 2

[0024] Step (1), step (2), step (4) are the same as in Example 1;

[0025] The difference in step (3) is:

[0026] Si + After the ion implantation is completed, the iron ions are implanted into the layer, and the implantation dose is 5×10 15 cm -2 , the injection energy is 70keV.

Embodiment 3

[0028] Step (1), step (2), step (4) are the same as in Example 1;

[0029] The difference in step (3) is:

[0030] Si + After the ion implantation is completed, cobalt ions are implanted into the layer, and the implantation dose is 1×10 15 cm -2 , the injection energy is 70keV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com